Inclination sensors

Inclination sensors

Inclination sensors

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Control systemsfor mobile vehiclesCatalogue 2009/2010www.ifm.com/gb/mobilefluid <strong>sensors</strong>and diagnosticsystemsposition<strong>sensors</strong>and objectrecognitionbus,identificationand control systems

The easy way to find what you are looking forHeader1 Section2 Heading3 Product4 Product group name5 Heading repeated6 Illustration1 2 3 4 5 6Sensors formobile applications<strong>Inclination</strong> <strong>sensors</strong>Sensors with CAN interface<strong>Inclination</strong> <strong>sensors</strong>Parameter setting of the displayresolution via the CAN bus.Compact and robust design.Signal output via CAN or via twoanalogue current interfaces.InclinometerZero point levelling and position detection of mobile machinesAngular Number Resolution / InterfaceDeviceWiring DrawingOrderrangeof axesaccuracyconnection diagramno.no. no.±15° 2 0.001° / 0.025° CAN M12 25 1 CR2101±45° 2 0.1° / 0.5° analogue / CAN M12 27 2 CR2102GeneralinformationList of articles14CAN interface with CANopen protocol.e1 type approval of the GermanFederal Office for Motor Traffic.Application exampleBlock diagram CR2101I/O modules Mobilecontrollers101112Inclinometers2-axis inclination sensorThe automation of vehicles and mobile machines can nolonger be imagined without controller electronics and<strong>sensors</strong>. Often the horizontal alignment of machines ormachine parts is an important requirement for reliableoperation. Typical examples are mobile cranes or accessplatforms.The inclinometer detects precisely the deviations of thetwo measurement axes (X and Y direction). As the sensormust often be mounted at difficult positions in thevehicle, special attention has been given to the mechanicaland electrical properties of the sensor during development.The high accuracy is achieved with measuringcells which operate to the conductometric principle. Thechange in conductivity of a liquid is determined. Dependingon the sensor inclination the electrodes are surroundedby a different level of liquid. This results in abehaviour comparable to that of a potentiometer. Dueto a suitable arrangement of the electrodes the signedvalues for the two axes are obtained.Connectors and splitter boxesType Description Orderno.Adapter cable for CAN deviceswith M12 connector (5-pole)Socket M128-pole, straight, 2 mSocket M128-pole, angled, 2 mSocket M12wirable, 5-pole, straightEC2062E80021E80022E11511Common technical dataHousing: aluminiumTemperature range: -30...80 °CProtection rating: IP 67Ub: 10...32 V DCCurrent consumption: 80 mA (at 24 V DC)Interface: CANCANopen: CiA DS 301 V 3 (V 4 CR2102)profile WDP 410Baud rate: 20...1,000 Kbits/sCE, e1 (only CR2102)+UBresetclockCAN8-bit2 1μController5+UB3 4Block diagram CR2102+UBreset DMUXclockAIout-X I A U DIout-Y I A 16-bitU D μControllerCANEEPROMsensorhybridEEPROMsensorGALclock generatorTechnical Accessories Connection SignalSensorsDiagnosis Dialogueinformationtechnology converters for mobile and service modulesand customerapplicationsservice151613Further accessories are available starting on page 143Further connectors and splitter boxes are availablestarting on page 127You can find scale drawings from page 187Sensors formobile applicationsSensorswith CANinterfaceAnalogue<strong>sensors</strong> /switchesSensors formobile applicationsInductiveefector m<strong>sensors</strong>Sensors formobile applicationsPressure <strong>sensors</strong>for mobilehydraulicapplications<strong>Inclination</strong><strong>sensors</strong>Inductive<strong>sensors</strong>Pressure<strong>sensors</strong>Page110 - 111112 - 113114 - 117118 - 1191101117 89Navigation bar7 Current heading8 Arrow = You are here9 Other headingsRight14 Technical data15 Block diagram, wiring diagrams of theunits or common technical data16 Current sectionLeft10 Special features of the units11 Recommended accessoriesand connectors12 Product description13 Notes for further details

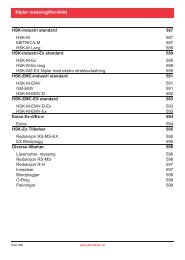

General informationNotes and explanations5 - 20GeneralinformationList of articlesOrder numbersin alphanumeric order23 - 25List of articlesMobile controllersControllers and software27 - 51MobilecontrollersI/O modulesI/O moduleswith CANopen interface53 - 67I/O-modulesDialogue modulesDisplays, input modulesand camera systems69 - 85DialoguemodulesDiagnosis and serviceRemote maintenance and data memory,CAN interface and CAN diagnosis87 - 99Diagnosisand serviceSensors formobile applications<strong>Inclination</strong> <strong>sensors</strong>,inductive <strong>sensors</strong>,pressure <strong>sensors</strong>101 - 119Sensorsfor mobileapplicationsSignal convertersFrequency, currentand voltage converters121 - 127SignalconvertersConnection technologyM12 connectors for <strong>sensors</strong>and actuators129 - 136ConnectiontechnologyAccessoriesAccessories for control systems139 - 152AccessoriesTechnical informationand customer serviceWiring diagramsScale drawingsTechnical glossaryifm information and ordering service156 - 178180 - 195196 - 200202 - 211Technicalinformationand customerservice3

General informationNotes and explanationsGeneral introduction 6 - 20Technicalinformationand customerserviceAccessoriesConnectiontechnologySignalconvertersGeneralinformationMobilecontrollersI/O-modulesSensorsfor mobileapplicationsDiagnosisand serviceDialoguemodulesList of articles5

General informationNotes and explanationsGeneral introductionControl technology for mobile applicationsLife today cannot be imagined without electronics in modern motor vehiclesand mobile machines. Many necessary and convenient functions could notbe implemented without electronic support. In contrast to electronics inconsumer goods and “normal” industrial applications such as packagingmachines and conveyors the requirements for components for mobile applicationsare much higher.RequirementsMobile machines and installations are often specially tailored to the applicationsand thus very expensive. Consequently, a high uptime of these costintensivemachines and installations is of utmost priority. The machine needsto provide extensive, simple and reliable diagnostic information enablingoperators to locate faults quickly, therefore reducing downtime. Safe operatingconcepts, adapted to the respective operating situation, help to avoidincorrect handling. Displays provide the necessary overview for the operator.The operating and system states must be stored for statistics and documentationby means of an operational data logger. Due to increasing legalrequirements for the machine manufacturers the systems are becomingmore and more complex. Against this background, networked electronicsystems are used in order to reduce wiring complexity.The bus system enables the decentralised arrangement of powerful input /output modules close to the <strong>sensors</strong> and actuators. The components aremounted where data are provided or required. In addition, the componentsmust be easy to mount and handle in case of service. This is achieved by themechanical design as well as by easy and clear integration during programming.Last but not least the components and devices used must withstand extrememechanical, climatic and electrical conditions and reliably function for a longtime. All above-mentioned requirements aim at: The development of reliable,cost-optimised and thus competitive machines.Electronic requirementsThe components need to be carefully selected, mainly because of the extrememechanical stress caused by impacts and shocks and the use at extremeoperating temperatures. The direct influence of dirt, humidity and wateroften cannot be excluded in field applications. Therefore a high protectionrating and a special selection of the materials are required for the devices.In addition to mechanical and environmental influences, electrical interferenceaffecting the whole system as well as individual devices, have to be takeninto account. A wide supply voltage range and well-adapted protectivemeasures ensure safe operation of the devices even in case of large voltagefluctuations by the battery / generator system. Strong conducted or radiatedinterference must not influence the function either.Modern shredderfor wood andwood waste. Onlyan extremelypowerful controlsystem such asecomatmobileallows safe andreliable operation.When therecycling materialis processed thewhole machineand thus also theelectronics areexposed to highimpacts.The electronicsare protected bymeans of specialhousing andinstallation concepts.As the electronicsare installedwithin themachine thecomponents areexposed to hightemperaturesfrom the dieselengine.Visit our website: www.ifm.com6

Notes and explanationsFor device networking the CAN bus has become the successful standard inthe last few years. Whereas for the high volume production of passengercars special, optimised and well-adapted protocols are used, the CANopenprotocol has become indispensable in mobile machines. Manufacturer andindustry-specific protocols, such as diagnostic engine data according to SAEJ 1939, the agricultural bus system (ISO bus) and the truck-trailer interfacefor articulated lorries can be coupled to the machine process via gateways.The most important functional unitsModern mobile machines consist of different segments. The automationcomponents of the ecomatmobile control system, particularly suited formobile applications, can be used for various tasks in these segments.Depending on the requirements they assume for example controlling, monitoringor displaying functions. Networking is made via the CAN bus with theCANopen protocol.Segment driveIn contrast to utility vehicles, often consisting of a truck and a body (e.g.a refuse truck), special machines are assembled from single elements by themanufacturer. The drive is therefore precisely adapted to the machine andthe later task (e.g. a mobile crane). It has to fulfil two essential tasks, onhighway as a vehicle and off highway operation as a construction machine.If safe operation on the highway is to be possible the control componentsmust meet safety requirements for road traffic use, defined by e1 type approval.Without e1 type approval the operating permit is invalid.When the vehicle arrives at the site where it is used it becomes a constructionmachine. Now, different conditions apply. The vehicle has to be suitedfor off-road use and needs to be easily manoeuvrable. The control componentsused are thus switched to the respective operating situation.Segment diesel engineSo-called industrial engines are mainly used in construction machines. Theseare engines which are ideally tailored to the requirements of the machinebuilder. Depending on the mechanical design and the performance ratingthey can be used for different purposes. Modern engines moreover featurea CAN interface which is accessible for the user. It is mainly designed accordingto the US standard SAE J 1939. In this standard the different CAN identifiersare assigned to the specific data of the engine, such as operating temperature,oil pressure, torque or rotational speed.For the control of the operating process these data are filtered by means ofthe gateway function of the R 360 controller and – if necessary – also processedwith the software. It is also possible to use the R 360 gateway functionto connect two networks operating at different transmission rates.The mobile craneat the constructionsite. Onlya sensible andreliable machinecontrol can meetthe requirements.GeneralinformationList of articlesMobilecontrollersI/O-modulesDialoguemodulesDiagnosisand serviceSensorsfor mobileapplicationsSignalconvertersConnectiontechnologyAccessoriesTechnicalinformationand customerserviceVisit our website: www.ifm.com7

General informationNotes and explanationsGeneral introductionSegment input and outputThe machine is operated by means of different control elements. By usingcabinet modules, I/O modules for use in operating and control panels, theinformation from joysticks, switches and pushbuttons is transmitted to theprocess controller via CAN bus where it is processed. The PDM360 graphicdisplay informs the operator about the machine’s operational status.Meaningful symbols and texts help to quickly locate possible errors. Operationaland diagnostic data can be stored on memory cards if necessary. Incase of service they provide significant information on the application andthe cause of the failure. If, in addition, the CAN / GSM radio modem CANcomis integrated into the network error messages can directly be sent to the servicedepartment or to the machine manufacturer. Especially with machineswhich are used worldwide considerable service cost savings can be made.Segment working element or vehicle bodyThis segment is the actual operating process of the machine. Decentralisedoutput modules trigger the hydraulic valves. For the operation of proportionalvalves these modules also feature current-controlled PWM outputs. Thecurrent value is transmitted via the bus and controlled by the module.Furthermore sensor signals are read by the bus modules and transmitted tothe process controller.In small machines as well as in large and complex systems whole functionalunits are controlled by intelligent slave modules such as the SmartController.These freely programmable devices directly process all relevant signals of thecorresponding machine function. Depending on the type of machine orvehicle only status messages and processed data are transmitted to otherparticipants in the network.The CAN / GSMradio modemdirectly transmitsmachine dataand error messagesto the servicedepartment.Robust I/O modulesfor decentraliseduse in mobileapplicationsVisit our website: www.ifm.com8

Notes and explanationsSafety technologyThere are functions in almost all mobile machines which may endangermaterial and persons. Many movements cannot be secured due to themachine’s size and the extreme conditions under which they are used. Thisalso explains why only a few, instructed people are allowed into the operatingareas of these systems. Of course the manufacturers do their best todesign safe machines which minimise the risk of accidents. Today, everymanufacturer has to comply with the general regulations for a safe machinedesign. But as these regulations and standards apply for many differentmachines they cannot be precisely adapted to the function of a specialmachine. Therefore there is an increasing number of product standardswhich are specifically tailored to these requirements.In some types of applications (e.g. vehicle lifts) there have been clear, definedproduct standards for some time now. The employers’ liability insuranceassociations also often have clear requirements towards the manufacturersof machines.For this reason there is an increasing demand for certified electronic assembliesfor mobile machines. The SafetyController can be used in applicationswhich require components up to safety category 3. The safety conceptmonitors all internal and external functions and safely switches off in thecase of an error. In future the CANopen protocol will also be used for thetransmission of safe data. The protocol addition CANopen Safety enablesthe transmission of safe and ”non-safe“ data on the same bus cable.GeneralinformationList of articlesMobilecontrollersI/O-modulesDialoguemodulesDiagnosisand servicebasic safety standardssafety groupstandardsproductstandardsB1 standardsgeneralsafetyrequirementstype Astandardsbasicsafetyrequirementsfor all machinestype B standardsB2 standardsspecialsafetyrequirementstype C standardsspecialsafety requirementsfor individual machinesClassificationof the differentsafety standardsfor machines andinstallations.Technicalinformationand customerserviceSensorsfor mobileapplicationsSignalconvertersConnectiontechnologyAccessoriesVisit our website: www.ifm.com9

General informationNotes and explanationsGeneral introductionRequirements for mobile and robust machine conceptsElectronic components are not only increasingly used in “normal” motorvehicles but also in modern mobile machines and installations.The following points sum up the main reasons for this development:High uptime of the machines and installations to minimise downtimecosts.Extensive, simple and safe system diagnosis for fast error locationdirectly by the operators.Safe and simple handling via displays and other input modulesaccording to the respective operating situation.Simple handling for mounting and service of the componentsin use owing to the modular concept.Reduced wiring by means of decentralisation: Powerful input / outputmodules are used where data are provided or required.Documentation of the operating and system states by meansof an operational data logger. With real-time clock, statistic andprotocol functions informative system reports can be created.These requirements can only be met with components precisely developedand made for the corresponding application.ifm electronic develops and makes such automation components andsystems. This includes a wide range of sensing and control products e.g. proximityswitches, pressure <strong>sensors</strong>, complex control systems and much more.ecomatmobilestands for highreliability underextreme operatingconditions.ecomatmobile, control technology for extreme conditionsThe components presented in this catalogue have been developed and optimisedfor increased requirements in close co-operation with our customersover a period of several years. ifm electronic now supplies a sophisticatedcontrol and automation system which conforms to the needs of the market.In addition to flexibility and performance attention was given to thefollowing points:Use even at extreme operating temperatures.Safety under extreme mechanical stress caused by impacts and shocks.Use even with direct exposure to dirt, water and humidityOperational reliability despite strong supply voltage fluctuationsby the battery / generator system.Insensitivity to conducted and radiated interferencein the whole electrical system.Application-related networking possible with the CAN bus systemsuitable for mobile applications.All componentswithstand impactsand shocks aswell as electricalinterference.Visit our website: www.ifm.com10

Notes and explanationsCAN – The fieldbus for mobile machinesThe basicsAt the beginning of the 1980s a bus system was developed in co-operationwith some automotive manufacturers, which preferably was to be used forengine management. About 20 years later this bus system – CAN (ControllerArea Network) – has become the standard in modern vehicles and mobilemachines and installations. When several machine parts (e.g. engine, driveand operating function) are networked to form a whole system, CAN providesdecisive advantages. Also, when the CAN bus was developed, the specialoperating conditions had already been taken into account.Therefore ifm electronic also uses this safe and reliable bus system for theecomatmobile control system.The “Controller Area Network” (CAN) is defined in the international standardISO 11898. It is based on the Producer / Consumer Network Model.It allows data to be very efficiently distributed to the other network participantsby means of the broadcast method. At the same time the Producer /Consumer Model also allows communication according to the master / slaveor peer-to-peer principles. These different principles are used depending onthe type of mobile machine and its special design.Especially whenseveral machineparts are interconnectedCANoffers decisiveadvantages.GeneralinformationList of articlesMobilecontrollersI/O-modulesDialoguemodulesvisualisationnetworkingWAN, Internet TCP/IPLAN, H1, Ethernet, ProfinetThe CAN busis used to read,write and processsensor and actuatorsignals.Diagnosisand serviceSensorsfor mobileapplicationscontrolprocessingInterbus, DeviceNet, Modbus,Profibus, CANAS-interfaceSignalconvertersinput/outputConnectiontechnologyThe CAN communication servicesIrrespective of the network configuration the transmission of the messagesalways takes place between a sending node (producer) and a receiving node(consumer). With CAN data transmission no addresses are assigned to theindividual participants. Instead, each message to be transmitted (e.g. oiltemperature, rotational engine speed) is given a clear identification mark(identifier) which is valid in the whole network. This identifier also definesthe priority of the message.This ensures that even in the case of simultaneous access by several participantsthe more important message is transmitted first. In contrast to otherbus systems the messages are not assigned a target address but an identificationmark (identifier). The message can be clearly identified by means ofthis identifier. CAN is therefore not a participant-oriented protocol but amessage-oriented protocol.AccessoriesTechnicalinformationand customerserviceVisit our website: www.ifm.com11

General informationNotes and explanationsGeneral introductionstation 1 station 2 station 3 station 4processmessagegeneratemessageprocessmessageCAN is not a participant-orientedbut a messageorientedprotocol.checkmessagesendmessagecheckmessagecheckmessagereceivemessagereceivemessagereceivemessageIn this example station 2, as the producer, generates a message and gives itto the bus. All other CAN participants receive this message at the same timeas consumers and check the identifier of the sent message. On the basis ofthe identifier each receiver decides whether it has to process the message (inthe example stations 1 and 4) or whether no reaction is required (in theexample station 3).This mechanism is called acceptance filtering. Transmission according to thebroadcast method thus relieves the network because several consumers canbe addressed by a single message at the same time. As each participant inthe network is constantly “listening” all participants have the same datainformation. Complex synchronisation and data management are not necessary.Due to the definition of certain identifiers which are used by a transmitterfor its messages and which at the same time trigger a reaction of one receiverpeer-to-peer connections can also be established. In this case all nodesare listening but only one participant reacts due to the identifier of the sentmessage. Peer-to-peer communication represents a possible variant to thebroadcast communication. Peer-to-peer connections are mainly used for thetransmission of device configuration data or for the upload / download ofprograms. The allocation of the identifiers to the respective messages of thebus participants can also be carried out in such a way that communication iscentrally managed via a master. Such a master / slave architecture is recommendedwhen new nodes are to be integrated into a CAN network withoutconsiderable configuration efforts. These only have to establish a communicationchannel to the master module, which then forwards the messages.Given that the bus is only accessed when data are to be transmitted the busloading can be easily controlled and monitored.An agriculturalmachine withcentralised controlunit.The structure of a CAN messageThe identifierA CAN message is composed of three main parts: The identifier, the datafield and the help and protective information for the data transmission. Theidentifier can be used as an 11-bit or 29-bit variant. 2,048 different messagescan be distinguished by means of the 11-bit identifier. This is sufficientfor most CAN protocols such as CANopen. The extended 29-bit identifier isfor example used in agricultural technology and also for the exchange ofengine data in accordance with SAE J 1939. Due to the large amount of differentmessages possible (536,870,912) certain information and data can beassigned to specific identifiers. For example this then allows all engine manufacturersto use the same specific messages.Visit our website: www.ifm.com12

Notes and explanationsstart ofmessagecontrolbitsend ofmessageStructure of theCAN message.GeneralinformationidentifierdataCRCList of articlesThe user data0 to 8 data bytes can be transmitted in the data field. It contains the actualinformation for the other network participants.Help and protective information for error detectionIn contrast to other bus systems, the CAN protocol does not acknowledgereceived data. If a bus participant detects an error, e.g. because of a faultychecksum (CRC), it immediately sends an error message and thus causes theabortion of the transmission or the rejection of the correct messages alreadyreceived by the other participants. It is therefore ensured that all participantshave correct and uniform data. Since the error message is directly transmittedthe sender can repeat the disturbed message immediately, as opposed tofieldbus systems (they wait until a defined acknowledgement time haselapsed).CAN data safetyWith the introduction of safety-related systems in mobile machines andinstallations the requirements for the safety of data transmission have increased.To avoid dangerous states the data protection must be high and theprobability of undiscovered errors must be low.Errors mainly occur if data are distorted by external influences (e.g. electromagneticinterference). A sensible statement on error probability can beachieved by means of a calculation model.If a data rate of 500 Kbits/s, an average bus load of 50 % and an averagemessage length of 80 bits are assumed you obtain the following values:With an operating time for the system of 8 hours a day on 365 days a yearand an error rate of 0.7 errors/s the statistical mean value is one undiscoverederror in 1000 years.Designing a CAN systemWith CAN, equal network participants (e.g. controllers, <strong>sensors</strong>, decentralisedinput / output modules) are interconnected via a serial bus. The electricalconnection is a three-wire line, consisting of the CAN H , CAN L and CAN GNDcables which are, depending on the requirements, screened or unscreened.MobilecontrollersI/O-modulesDialoguemodulesDiagnosisand serviceSensorsfor mobileapplicationsSignalconvertersConnectiontechnologyAccessoriesTechnicalinformationand customerserviceVisit our website: www.ifm.com13

General informationNotes and explanationsGeneral introductionThe structure of the networkThe ISO 11898 standard assumes a line structure of the CAN network. Inaddition the CAN H and CAN L cables must be provided with a 120 Ω terminatingresistor on each end.Node 1Node nGeneralstructure of aCAN network.CAN_H120CAN Bus Line120CAN_LIdeally, no spur should lead to the bus participants (node 1... node n) becausedepending on the total cable length and the transmission time, reflectionsmay occur on the bus. However, in practice this requirement often cannot beimplemented. In order to avoid that the spurs to a bus participant (e.g. to anI/O module) cause system errors they should not exceed a certain length.Spurs up to a length of 2 m are considered to pose no problem. The sum ofall spurs in the whole system should not exceed 30 m. In any case a networkdesign should be examined under real conditions (field test) in practice.The length of the bus cable depends on the characteristics of the bus connection(cable, connector), the cable resistance and the necessary transmissionrate (baud rate). As described above, the length of the spurs must alsobe considered for the network design. Simplified, the following dependencebetween bus length and baud rate can be assumed:The maximumdata transmissionrate depends onthe length of thebus cable.baud rate [Kbits/s]10005002001005020105010 50 100 200 100010000bus length [m]Visit our website: www.ifm.com14

Notes and explanationsCANopenTo make things even simpler for the CAN user the standardised protocollayer CANopen is based on the existing definitions. More and more manufacturersof machines and installations join to form “user groups” to maketheir specific definitions on the basis of these standards. This is why CANwith the protocol layer CANopen provides the future-oriented and flexiblebasis for a bus system in mobile machines and installations.General information on CANopenThe CAN functions described above control the physical link and the datatransmission between the bus participants. For a practical CAN applicationthis means that the programmer is responsible for the definition of the dataprotocol for the specific application.To obtain a uniform protocol for networking different CAN participantsCANopen has been defined. It defines the meaning of the data for the correspondingdevice type (e.g. I/O module, drive, encoder, etc.). With thesedefinitions the application programmer can access many components fromdifferent manufacturers with CANopen capability without any intensivework on the protocol. CANopen participants which belong to the same devicefamily have their data organised in the same way. The characteristics ofthese device classes are indicated in the “device profiles”.Despite this definition the basic CAN structure which allows each bus participantto send messages (data) to the network is maintained. Only the networkmaster (NMT master) exists once and is used, among others, for theinitialisation and monitoring of the system.A list of device parameters is defined in CANopen nodes in the object directory(OD) in which all settings are described and stored. It does not onlyserve as a device description but also as an interface for the access to thedata by other CANopen devices.Larger, non time-critical data volumes are transmitted via “Service DataObjects” (SDOs). In addition there are at least two “Process Data Objects”(PDOs) for transmitting and receiving time-critical process data.Monitoring of the participants and the network is also carried out via CANobjects. The “Nodeguarding Object” or the “Heartbeat” monitors if a participantresponds within a defined time. “Emergency Objects” are transmittedfor the display of hardware and software errors.CAN in ecomatmobile componentsAll devices described in this catalogue with CAN interface support theCANopen protocol.When using CANopen devices from ifm electronic configuration can becarried out by means of the programming software and the control modules(network master) but also by means of external tools (PC software, CANviewanalyser).Which tool is best suited depends on the complexity and on the systemrequirements. ifm electronic supports project engineers and programmerswith the appropriate tools and services.GeneralinformationList of articlesMobilecontrollersI/O-modulesDialoguemodulesDiagnosisand serviceSensorsfor mobileapplicationsSignalconvertersConnectiontechnologyAccessoriesTechnicalinformationand customerserviceVisit our website: www.ifm.com15

General informationNotes and explanationsGeneral introductionAutomation of a mobile machineWhich devices are suited for the individual applications mainly depends onthe design of the machine or installation. Also, the service and mountingconcept is important for the device selection.For the sake of simplicity a distinction is made between three concepts:Machines with central controllerIn general, these are machines with fewer operating functions. Only a fewcontroller inputs and outputs are needed.Controller module with suitable I/O configuration (e.g. CR0020).Dialogue module to display system states and diagnostic data. Dependingon the requirements a PDM360 display with graphic capabilities(e.g. CR1050) or the PDM360 smart display (e.g. CR1070).F1esc F2 F3 F4 F5 F6Extreme shockand vibration:Reliable functionof the sensitiveelectronics mustbe guaranteedunder harshoperating conditionsas well.Typical applications:Equipment mounted on agricultural machines, access platforms, compactconstruction machines, simple monitoring and diagnostic modules.Machines with distributed intelligenceMachines, which can be split up in logical function blocks, can often be operatedwith several stand-alone controller modules. The input and outputrequirement of these machines is higher and often includes several independentcontroller elements. Only a few data have to be exchanged between theindividual controllers.Two or more controller modules with suitable I/O configuration (e.g.CR0020 / CR0505). Each module has its own application program. Data,which are important for the whole system, are provided via the CAN bus.Dialogue module to display system states and diagnostic data.Depending on the requirements a PDM360 colour display with graphiccapabilities (e.g. CR1051) or the PDM360 smart display (e.g. CR1070).Typical applications:Complex construction machines, mobile cranes, aircraft tractors, multipleunitvehicles, fork-lift trucks.Typical exampleof a machinewith a centralcontroller.Distributedintelligence: Inthe differentfunctionalsegments ofmobile cranessegment-specificcontrol units areoften used.Visit our website: www.ifm.com16

Notes and explanationsMachines with decentralised control technologyFor reducing the wiring complexity a decentralised machine design is recommended.Several decentralised input / output modules are connected to acentral controller. Via the CAN bus the data are read and processed in thecontroller and then transferred again to the I/O modules. Depending on thecomplexity of the installation the correct design of the bus system must beensured.Controller module with suitable I/O configuration (e.g. CR0505).One or several decentralised input / output modules which are networkedvia the CAN bus (CANopen protocol).Dialogue module to display system states and diagnostic data. Dependingon the requirements a PDM360 display with graphic capabilities(e.g. CR1051) or the PDM360 smart display (e.g. CR1070).CAN slavesSensorsfor mobileapplicationsDialoguemodulesGeneralinformationList of articlesMobilecontrollersI/O-modulesF1esc F2 F3 F4 F5 F6CAN masterDiagnosisand serviceCAN/CANopenTypical applications:Complex construction machines, drilling tools, municipal vehicles.Typical exampleof a machine witha decentralisedcontroller.SignalconvertersConnectiontechnologyDecentralisedcontrol technologyis oftenused in municipalvehicles.AccessoriesTechnicalinformationand customerserviceVisit our website: www.ifm.com17

General informationNotes and explanationsGeneral introduction3 steps to define the mobile control systemStep 1: Definition of the automation conceptFirst the automation concept must be defined. It depends on the size of themachine and complexity of the control task. Integration of the system componentsand after-sale service must also be taken into account when thesystem is designed.Small compact machines are often fitted with a central control system. Ifnecessary, some actuators, e.g. remote valve blocks, are connected to thesystem via a CAN module. Since components without the required protectionrating are often used they are mounted in a control cabinet. For practicalreasons the controller is then also installed there.If there is acontrol cabinetanyway, thecontroller is oftenalso mountedthere for practicalreasons.If it is possible from a technical and commercial point of view, the structureshould be decentralised. To do so, the machine is divided into logical functionunits. Hydraulic valve blocks, <strong>sensors</strong> and machine specific functions aredivided into a clearly structured network. The advantage: In case of a serviceonly individual modules have to be checked and replaced, if necessary.The following points should be taken into account for the systemdesign.Where are the system components positioned? Are they protectedagainst extreme mechancial stress (e.g. impact from stones or otherdebris on the connector system)? Extreme temperatures (e.g. hotasphalt) can also influence the components.Which wiring is chosen (material and cable design)?Where are the cables routed?Node1Node2Node3Node1Node2Node3Node1Node2Node3When the CANnetwork isdesigned, thenetwork structuremust be takeninto account.CAN_LCAN_HCAN_HCAN_HCAN_LCAN_LNode4Node5Node4Node5Node4Node5RingLinie/LineStern/StarVisit our website: www.ifm.com18

Notes and explanationsHow can an optimum network structure be implemented?Which operating concept is planned? Conventional design with mechanicalswitches and pushbuttons wired onto the controller module or anI/O module? Or is the machine to be operated via a dialogue module,e.g. PDM360?Which diagnostic and service functions are planned? Are system messagesto be displayed or transferred via CANcom / GPS with position informationof the machine, if needed?Can functions be grouped? In particular for the implemention of relaycontrolledsystems using CAN modules and operating functions in dialoguemodules often reduces the number of the required inputs andoutputs.GeneralinformationList of articlesMobilecontrollersStep 2: Selection of the componentsIn most cases selection of the system components is based on the neededdata. So the number of the inputs and outputs and their function must beconsidered. The controllers and I/O modules of the ecomatmobile systemare configurable in many ways. Almost all requirements for the systemdesign can therefore be implemented.If components are mounted in the exposed part of the machine, the devicesshould have the protection rating IP 67.The CompactModules are an excellent choice for applications that are toextend the machine functions at a later point in time. Even if machines witha variety of options are made, compact modules are the first choice. Flexibilityof the SmartModules is fully utilised if they are connected using a prewiredcable harness.The controllers and modules of the Cabinet series are intended for use in thecab or control cabinets.For machines with open control panels, using a monochrome PDM360 withtransflective display is recommended, as even frontal sun radiation does notinfluence readability.Irrespective ofthe applicationecomatmobilealways offersa solution.I/O-modulesDialoguemodulesDiagnosisand serviceSensorsfor mobileapplicationsSignalconverters32 bit Conroller16 bit ConrollersI/O modulesDialogue modulesClassic Classic Smart Cabinet Compact Smart Cabinet Keypad PDM360 PDM360ExtendedcompactPDM360smartConnectiontechnologySmallapplicationComplexmachinesSafetyrequirementsMachineswith cabinMachineswith opencontrol panelEnginediagnosis•••••••••••••••••••••••••••••••••••AccessoriesTechnicalinformationand customerserviceVisit our website: www.ifm.com19

General informationNotes and explanationsGeneral introductionStep 3: Programming and network configurationThe R 360 controllers are programmed with the software CoDeSys. All therequired functions for parameter setting of the CANopen modules, triggeringof the dialogue modules and for the complex control functions areavailable.It makes sense to implement the machine functions with individual softwaremodules, so-called function blocks, and to test them individually. The softwarecan then be organised more clearly. Function blocks have one moreadvantage. Implemented functions can be grouped in libraries and used inanother project later on.Extensive software tools support the programmer to implement the application.The “downloader” program enables loading of the controller softwareindependently of the programming system. This function is mainly used inproduction because downloading can be automated via an easy batch processing.In combination with the CAN interface CANview, the bus monitoring softwareCANmon enables exact monitoring of the communication data on thebus.Depending on the monitoring profile selected the data are commented andfiltered. Incorrect settings can be determined quickly and reliably.CAN busmonitoring withCANmon.programmingprojectiondocumentationevaluationvisualisationevaluationFrom projectionup to visualisationecolog softwarein practice.SD-CardCANmemCANcomGSMinternetVisit our website: www.ifm.com20

Notes and explanationsTechnicalinformationand customerserviceAccessoriesConnectiontechnologySignalconvertersSensorsfor mobileapplicationsDiagnosisand serviceDialoguemodulesI/O-modulesMobilecontrollersList of articlesGeneralinformation21

List of articlesOrder numbersin alphanumeric orderControl systems 24 - 25Technicalinformationand customerserviceAccessoriesConnectiontechnologySignalconvertersGeneralinformationMobilecontrollersI/O-modulesSensorsfor mobileapplicationsDiagnosisand serviceDialoguemodulesList of articles23

List of articlesOrder numbersin alphanumeric orderControl systemsOrderno.ApprovalsCataloguepageOrderno.ApprovalsCataloguepageOrderno.ApprovalsCataloguepageCP9006 49 85CP9008 49 85CR0020 37CR0032 39CR0200 41CR0301 47CR0302 47CR0303 47CR0505 37CR1050 81CR1051 81CR1052 79CR1053 79CR1055 79CR1056 79CR1060 81CR1070 77CR1071 77CR1500 67CR2012 65CR2014 65CR2016 65CR2031 61CR2032 61CR2033 61CR2101 111CR2102 111CR2500 43CR2512 63CR2513 63CR3001 127CR3002 127CR3003 127CR3004 127CR3101 97CR3105 95CR3106 95CR7020 45CR7200 45CR7505 45E10735 151E10736 151E10737 151E11048 151E11049 151E11187 135E11277 135E11416 134E11417 134E11418 134E11419 134E11420 134E11504 132E11505 132E11506 132E11511 130E11589 130E11590 132E11591 135E11592 135E11593 135E11594 135E11595 135E11596 130E11597 130E11598 132E11599 132E11622 135E11898 141E11949 135E21137 136E21138 136E21139 136E73004 146E80021 131E80022 131EC1021 150EC1410 147EC1411 147EC1412 147EC1413 147EC1450 148EC1451 148EC1452 146EC1453 146EC1520 142EC1521 142EC1522 143EC1523 143EC2013 141EC2015 152EC2016 152EC2019 113EC2025 127EC2032 144EC2034 144EC2036 150EC2045 113EC2046 141EC2049 127EC2050 143EC2053 142EC2056 143EC2058 145EC2059 150EC2060 113EC2061 113EC2062 143EC2063 144EC2068 140EC2070 99EC2071 99EC2074 51EC2075 142EC2076 145EC2077 140EC2080 140EC2081 140EC2082 113EC2083 146EC2084 141EC2086 141EC2088 144EC2089 142EC2090 142EC2091 145EC2092 150EC2093 150EVC001 130EVC002 130EVC003 130EVC004 130EVC005 130EVC006 130EVC010 134EVC011 134EVC012 134EVC013 134EVC014 134EVC015 134EVC016 134EVC017 134EVC018 134EVC019 134EVC030 134EVC031 134EVC032 134EVC033 134EVC034 134EVC055 135Visit our website: www.ifm.com24

Order numbersin alphanumeric orderOrderno.ApprovalsCataloguepageEVC056 135EVC057 135EVC058 135EVC059 135EVC060 135EVC061 135EVC062 135EVC063 136EVC064 136EVC065 136EVC066 136EVC067 136EVC068 136EVC069 136EVC070 131EVC071 131EVC072 131EVC073 131EVC074 131EVC075 131EVC076 132EVC077 132EVC078 132EVC079 132EVC080 132EVC081 132EVC094 133EVC095 132EVT010 130EVT011 130EVT012 130EVT013 130EVT014 130EVT015 130EVT043 135IFM203 117IFM204 117IFM205 115IFM206 115IFM207 117IFM208 117IFM209 115IFM210 115IGM200 117IGM201 117IGM202 117IGM203 117IGM204 115IGM205 115IGM206 115Orderno.ApprovalsCataloguepageIGM207 115IIM200 117IIM201 117IIM202 117IIM203 117IIM208 115IIM209 115IIM210 115IIM211 115IN5281 117IN5282 117O2M110 83PA3020 119PA3021 119PA3022 119PA3023 119PA3024 119PA3026 119PA3060 119PA9020 119PA9021 119PA9022 119PA9023 119PA9024 119PA9026 119PA9060 119PP2001 151PP7550 119PP7551 119PP7552 119PP7553 119PP7554 119PP7556 119GeneralinformationList of articlesMobilecontrollersI/O modulesDialoguemodulesDiagnosisand serviceSensorsfor mobileapplicationsSignalconvertersConnectiontechnologyAccessoriesTechnicalinformationand customerserviceVisit our website: www.ifm.com25

Mobile controllersTechnicalinformationand customerserviceAccessoriesGeneralinformationMobilecontrollersI/O-modulesDialoguemodulesDiagnosisand serviceConnectiontechnologySignalconvertersSensorsfor mobileapplicationsList of articlesControllers and softwareSystem descriptionSelection chartClassicController 16 bitClassicController 32 bitExtendedController 16 bitSmartController 16 bitSafetyController 16 bitCabinetController 16 bitCoDeSys software and toolsStarter set28 - 3334 - 3536 - 3738 - 3940 - 4142 - 4344 - 4546 - 4748 - 4950 - 5127

Mobile controllersControllers and softwareSystem descriptionIntroductionIn the meantime the 3rd generation of the ecomatmobile controller is available.Due to the new and extended functions it is a universal and userfriendlycontrol system used in a wide range of applications worldwide.The powerful 16-bit microcontroller enables a very short cycle time of theapplication program. The large program memory allows the processing ofcomplex application programs. A second integrated 8-bit microcontrollermonitors the important system functions such as cycle time or hardwaretimer.All common data types like BIT, WORD, STRING, REAL (floating decimalpoint) and extensive function libraries are available to the user for programming.They are used to solve among others mathematical tasks (e.g. arithmetic,trigonometric and standardisation functions) and implement controlfunctions (e.g. PID controller, synchro controller). Libraries for CAN andCANopen communication, exchange of data with dialogue modules and differentgateway functions (e.g. SAE J 1939) offer the programmer a convenientsoftware interface to the other network components.In addition to digital inputs and outputs the controller also has analogueports. Inputs for fast signals up to 50 kHz can additionally be used. Eachdevice has 8 or 16 PWM outputs, some of which are current-controlled. Theinputs and outputs are protected against interference and overload.The ports support diagnostic functions for signal monitoring. All deviceshave a wide-range power supply for operation in 12/24V on-board supplysystems. Integrated safety functions monitor the program run and reliablyswitch off the outputs, if necessary (SafetyController).The 3rd generationof thecontroller family:R360.Visit our website: www.ifm.com28

Controllers and softwareImportant technical data for the R360 controllerMechanical resistance to exteme shocksHigh protection rating (IP 67) for outdoor usePowerful microcontrollers (C167CS or TriCore 1796) for short cycle timesIncreased functional reliability by means of permanentcheck sum test of the program and system8-bit parallel processor to monitor the main processorLoad-dump resistanceDiagnostic functions for inputs and outputsCurrent-controlled PWM channelsCurrent, voltage and ratiometric measurement throughparameter setting of analogue channels0...30 kHz frequency inputs with the option to connectincremental encodersMonitoring and measurement of the supply voltageand device temperature2 or 4 CAN interfaces with CANopen protocol and free protocol(layer 2) for program download and communicationSerial RS-232 interface for program download and communicationUse as safety-related controller according to IEC 61508 / EN 13849Free programming to IEC 61131-3 with the standardised languagesfunction block diagram (FBD), ladder diagram (LD), instruction list (IL),sequential function chart (SFC) and structured text (ST)Technicalinformationand customerserviceGeneralinformationList of articlesMobilecontrollersI/O-modulesDialoguemodulesDiagnosisand serviceSensorsfor mobileapplicationsAccessoriesConnectiontechnologySignalconvertersVisit our website: www.ifm.com29

Mobile controllersControllers and softwareSystem descriptionClassicControllerThe ClassicController is the basic device of the R360 controller family. Thefirst generation was a universal platform for a wide range of applicationswith its numerous configurable inputs and outputs.The latest generation of this controller is available in two types, they enableimplementation of many device variants due to their flexible configuration.The great advantage: storage at the OEM and for service on site is considerablyreduced.The ClassicController is available as 16-bit variant with 24 or 40 inputs andoutputs and as 32-bit variant with 32 multifunctional inputs and outputs.The function is defined in the user program.ExtendedControllerLike the ClassicController, the ExtendedController supports the various functionsof the configurable inputs / outputs and interfaces. In one housing itprovides up to 80 inputs / outputs, connection is made via two 55-way connectors.Depending on the selected mode the ExtendedController can be used withsimple or dual CPU function. As default, 80 inputs / outputs are available. Allfunctions are managed by the central CPU and programmed via a user programto IEC 61131-3.In the “dual CPU” mode the user can access two separately programmablecontrollers with 40 inputs / outputs each. But the internal synchronised datainterface still enables easy exchange between separately running processors.High flexibilityfor a wide rangeof applications:The Classic-Controller.SmartControllerThe SmartController performs different control functions. Programmable toIEC 61131-3 like all controllers of the ecomat moble system, it can be adaptedto different requirements. Whether it serves as an intelligent slave in adistributed system, as gateway between different CAN systems (SAE J 1939 /CANopen) or as controller for small stand-alone machines, the SmartControllerperforms all tasks. In this device it is also possible to set the parametersof the input and output function via the user program.SafetyControllerThe ClassicController for safety-related appliations up to the safety category 3(EN 954-1) is called SafetyController. In this device special test routines forhardware and software monitoring are implemented. Nevertheless, the controllersare easily and conveniently programmable via CoDeSys. Due to thecertification of the hardware, operating system software and programmingtools it is easy for the project engineer to get the approval for the machine.Full concentration can be given to the application program.feedback signalsBasic device structurein controllersup to the safetycategory 3.signalgeneratorcontrolelectronicsdecouplingmachinecontrolelectronicsVisit our website: www.ifm.com30

Controllers and softwareCabinetControllerThe CabinetController is suitable for signal processing, in particular in operatingpanels. To connect the switches, <strong>sensors</strong> and actuators the importantpotentials are available at the device connectors. No further terminals areneeded. The flat design enables integration in dashboards and operatingpanels. The CabinetController is also used in control cabinets of small standalonemachines. Free programming via CoDeSys enables evaluation and processingof the signals directly where they are provided.GeneralinformationList of articlesFor installation indashboards andoperating panels:The CabinetController.MobilecontrollersI/O-modulesDialoguemodulesConfigurabilityAnalogue inputsThe analogue inputs can be configured via the user program. They can beused as 0/4...20 mA current inputs and as voltage inputs. In the functionvoltage input the measuring range 0...10 V or 0...32 V can be selected. If theoperating mode 0...32 V is selected it is possible to read back the systemsupply voltage. This allows the measurement to be performed ratiometrically.Potentiometers or joysticks can then be evaluated without additionalreference voltage. Supply voltage fluctuations have no influence on themeasured value. As an alternative, an analogue channel can also be evaluatedas a digital input.U BBlock diagramof the analogueinputs.Diagnosisand serviceSensorsfor mobileapplicationsSignalconvertersConnectiontechnologyAccessoriesanalogue inputreferencevoltageTechnicalinformationand customerserviceEMCfiltervoltagecurrent measurementvoltage measurement0… 10/32 VVisit our website: www.ifm.com31

Mobile controllersControllers and softwareSystem descriptionDigital inputsDepending on the controller, digital inputs are available with different configurationoptions. In addition to the protective mechanisms against interferencethe digital inputs are internally evaluated via an analogue converter.This enables diagnosis of the input signals. In the application software theinput signal is provided as bit information. For some of the digital inputs thereference potential is selectable. The input can then be adapted to positiveor negative signals.Block diagramhigh-side /low-side inputfor negativeand positivesensor signalsdigital inputEMCfiltervoltageHigh-side inputfor negativesensor signals.U BU BLow-side inputfor positive <strong>sensors</strong>ignals.SensorSensorGNDGNDInputs with special input filters enable a frequency and period measurementup to 50 kHz. Due to a software function block for CoDeSys encoders can beeasily and conveniently evaluated.Visit our website: www.ifm.com32

Controllers and softwareDigital and PWM outputsFor the controller outputs three types can be differentiated:High-side digital outputs with or without diagnostic functionHigh-side digital outputs with or without diagnostic functionand additional PWM modePWM outputs with or without current control functionCurrent-controlled PWM outputs are mainly used to trigger proportionalhydraulic functions.The Classic and ExtendedControllers also enable selection of high and lowsideoutputs. This allows the implementation of H bridges, e.g. to triggerdirectional electric motors, in these devices.High-sideoutput forpositive signal.U BU BHere triggeringof the proportionalhydraulicfunctions is performedby current-controlledPWM outputs.GeneralinformationList of articlesMobilecontrollersI/O-modulesLast/loadDialoguemodulesLast/loadDiagnosisand serviceGNDGNDLow-sideoutput fornegative signal.Sensorsfor mobileapplicationsFurther important functions:Gateway functionsAll controllers have at least one CAN interface which is used to transfer data,e.g. to the decentralised input / output modules or to a dialogue modulethrough the CANopen protocol. The CANopen protocol enables fast and flexibleconnection to the bus.Controllers with more than one CAN interface can be used as gateway. Twodifferent CAN networks can be easily connected to each other. They enabledirect processing of for example control and diagnostic data of diesel engineswith SAE J 1939 protocol. As an alternative the second CAN interfacecan also be used for freely definable CAN messages (CAN layer 2). For theSmartController CR2501 the second interface is designed as “truck-trailerinterface” to ISO 11992.Programmable to IEC 61131-3Programming via CoDeSys with the programming languages from the standardIEC 61131-3 enables the user to create clear and easy application software.Function libraries are available for the special hardware functions (e.g.gateway SAE J 1939 / CANopen).SignalconvertersConnectiontechnologyAccessoriesTechnicalinformationand customerserviceVisit our website: www.ifm.com33

Mobile controllersControllers and softwareSelection chartTypeTotalnumbers ofinputs /outputsCANInterfacesRS-232CANgatewayfunctionArea of appl.FieldControlcabinetTÜV approvalIEC 61508EN 13849PageMobile controllers R360ClassicController 16 bit40 2 1 • • ––3624 2 1 • • – –36ClassicController 32 bit32 4 1 • • – –38ExtendedController 16 bit80 4 2 • • – –40SmartController 16 Bit12 2 1 • • – –42SafetyController 16 Bit40 2 1 • • – •24 2 1 • • – •4444SafetyController 16 Bit80 4 2 • • – •44CabinetController, 42 I/O42 1 1 – – • –46CabinetController, 36 I/O361 1 – – • –46CabinetController, 42 I/O422 1 • – • –4634

Controllers and softwareTypeTotalnumbers ofinputs /outputsCANInterfacesRS-232CANgatewayfunctionArea of appl.FieldControlcabinetTÜV approvalIEC 61508EN 13849PageGeneralinformationStarter setStarter setList of articles12 2 1 • – – –50System software for mobile controllersMobilecontrollersCoDeSys + tools–DownloadviaCANDownloadviaRS-232– – – –48I/O-modulesTechnicalinformationand customerserviceAccessoriesConnectiontechnologySignalconvertersSensorsfor mobileapplicationsDiagnosisand serviceDialoguemodules35

Mobile controllersControllers and softwareClassicControllerInputs for analogue, digital,diagnostic and pulse signals.Digital, PWM or current-controlledoutputs, H-bridge function.Freely programmableto IEC 61131-3.2 gateway interfaces, protocols forCANopen, SAE J 1939, ISO 11992.e1 type approval of the GermanFederal Office for Motor Traffic.ClassicController 16 bitRobust controller for mobile useThe ClassicController has been specially developed foruse in vehicles and mobile machines. Many years ofexperience with the development and construction ofmobile controllers have been applied to the new devicegeneration.The user can select the requested function of the inputsand outputs through parameter setting. Thus the samecontroller module can be used for different requirements.This reduces storage. In addition to the flexibleI/O level each controller module is equipped with twoCAN interfaces. A freely programmable CAN gatewaycan be implemented for coupling different networks. Itsupports all important bus protocols. This enables aneasy exchange of SAE J 1939 engine and CANopendata. Different transmission rates and the transparent orpreprocessing exchange of data between the networksare supported. The user can easily integrate all functionsin the application program via programming to IEC61131-3.Connectors and splitter boxesType Description Orderno.Connector AMP 55-polewirable, with contactsConnector wiredcable length 2.5 mConnector wiredcable length 1.2 mCable with connectorcores sealed individually, 1.2 mProgramming software CoDeSys+ tools, GermanProgramming software CoDeSys+ tools, EnglishEC2013EC2046EC2086EC2084CP9006CP9008Further accessories are available starting on page 139Further connectors and splitter boxes are availablestarting on page 129Mobile controllersClassic-ControllerExtended-ControllerSmart-ControllerSafety-ControllerCabinet-ControllerCoDeSyssoftwareand toolsStarter setControllersandsoftwarePage36 - 3940 - 4142 - 4344 - 4546 - 4748 - 4950 - 5136

Controllers and softwareClassicController 16 BitAnalogue, digital, diagnostic and pulse inputsDigital, PWM or current-controlled outputs, H-bridge functionInputs /outputstotalInputsdigital /analogueInputs dig. /frequency(pos. / neg.)Inputsdigital(pos. / neg.)InputsdigitalOutputsdigital / PWM /curr.-controlledOutputsdigitalOutputsdigitalPWMFunctionH-bridgeWiringdiagramno.40 8 8 8 16 8 12 4 2 1 1 CR002024 8 8 – 8 8 – – – 2 1 CR0505Drawingno.Orderno.DialoguemodulesGeneralinformationList of articlesI/O modulesMobilecontrollersApplication exampleBlock diagramDiagnosisand serviceV BBSV BBR5V3.3 VresetwatchdogSensorsfor mobileapplicationsV BBOCommon technical data55-pole connectiondigital OUTanalogue INdigital INTESTRS 232CAN 1CAN 216-bitμControllerRAM2x128kbytesFRAM32 kbytesFlash2048 kbytesclockaddressdecoderSignalconvertersConnectiontechnologyAccessoriesHousing: metalConnection: 55-pole AMP connectorTemperature range: -40...85 °CProtection rating: IP 67Ub: 10...32 V DCSwitching current outputs: 4 A / 2 AInterfaces: 2 x CAN 2.0, 1 x RS-232Program memory: 768 kB flashData memory: 128 kB SRAM, 128 kB flashData memory (non volatile): 17 kBCE, e1, appr. for railway applic. (EN 50155)Technicalinformationand customerserviceYou can find scale drawings from page 18037

Mobile controllersControllers and softwareClassicControllerInputs for analogue, digital,diagnostic and pulse signals.Digital, PWM or current-controlledoutputs, H-bridge function.Freely programmableto IEC 61131-3.4 gateway interfaces, protocols forCANopen, SAE J 1939, ISO 11992.e1 type approval of the GermanFederal Office for Motor Traffic.ClassicController 32 bitRobust controller for mobile useThe ClassicController has been specially developed foruse in vehicles and mobile machines. Many years ofexperience with the development and construction ofmobile controllers have been applied to the new devicegeneration.The user can select the requested function of the inputsand outputs through parameter setting. Thus the samecontroller module can be used for different requirements.This reduces storage. In addition to the flexibleI/O level each controller module is equipped with fourCAN interfaces. A freely programmable CAN gatewaycan be implemented for coupling different networks. Itsupports all important bus protocols. This enables aneasy exchange of SAE J 1939 engine and CANopendata. Different transmission rates and the transparent orpreprocessing exchange of data between the networksare supported. The user can easily integrate all functionsin the application program via programming to IEC61131-3.Connectors and splitter boxesType Description Orderno.Connector AMP 55-polewirable, with contactsConnector wiredcable length 2.5 mConnector wiredcable length 1.2 mCable with connectorcores sealed individually, 1.2 mProgramming software CoDeSys+ tools, GermanProgramming software CoDeSys+ tools, EnglishEC2013EC2046EC2086EC2084CP9006CP9008Further accessories are available starting on page 139Further connectors and splitter boxes are availablestarting on page 129Mobile controllersClassic-ControllerExtended-ControllerSmart-ControllerSafety-ControllerCabinet-ControllerCoDeSyssoftwareand toolsStarter setControllersandsoftwarePage36 - 3940 - 4142 - 4344 - 4546 - 4748 - 4950 - 5138

Controllers and softwareClassicController 32 BitAnalogue, digital, diagnostic and pulse inputsDigital, PWM or current-controlled outputs, H-bridge functionInputs /outputstotalInputsdigital /analogueInputs dig. /frequency(pos. / neg.)Inputsdigital(pos. / neg.)InputsdigitalOutputsdigital / PWM /curr.-controlledOutputsdigitalOutputsdigitalPWMFunctionH-bridgeWiringdiagramno.32 16 16 16 16 16 16 16 2 3 1 CR0032Drawingno.Orderno.DialoguemodulesI/O modulesMobilecontrollersGeneralinformationList of articlesApplication exampleBlock diagramDiagnosisand serviceinputterminalEMCprotectioninput group 16 channelssignalprocessingswitching between sectionsand operating modesoutput group 16 channelsdigital and PWM outputcurrent measurement and diagnosisoutputterminalSignalconvertersSensorsfor mobileapplicationsImpedance transformationcomparatorADC, counter, ...current measurement,PWM, diagnosisConnectiontechnologyCommon technical datamain processor 32-bit CPU Infineon TriCore 1796S-RAMFRAMAccessoriesHousing: metalConnection: 55-pole AMP connectorTemperature range: -40...85 °CProtection rating: IP 67Ub: 10...32 V DCSwitching current outputs: 4 A / 2 AInterfaces: 4 x CAN, 1 x RS-232, 1 x USBProgram memory: 1.25 MB flashData memory: 256 kB SRAMData memory (non volatile): 56 kB FRAMCE, e1, appr. for railway applic. (EN 50155)supplyterminalsEMCprotection10...32 V5.0 V3.3 V1.5 Vvoltagesupplyrelayrelaycoprocessorvoltage monitoringwatchdogspecial functionstest input, LEDCAN interfaceCAN interfaceCAN interfaceCAN interfaceRS-232 interfacevirt. COM port(USB hardware)referencevoltage outputTechnicalinformationand customerserviceYou can find scale drawings from page 18039

Mobile controllersControllers and softwareExtendedControllerInputs for analogue, digital, diagnosticand pulse signals.Digital, PWM or current-controlledoutputs, H-bridge function.Freely programmableto IEC 61131-3.2 gateway interfaces, protocols forCANopen, SAE J 1939, ISO 11992.Extended ClassicController with80 input / output channels.ExtendedController 16 bitTwin-packed mobile controllerIf many inputs and outputs are required in mobilemachines and installations, the ExtendedController isused. Like the ClassicController, it supports the numerousfunctions of the configurable inputs / outputs andinterfaces.Depending on the selected operating system the ExtendedControllercan be used with single or dual CPU function.As default, 80 inputs and outputs are available.Furthermore, this operating mode supports two CANinterfaces for the freely programmable CAN gatewayfunctions. All these functions are managed by the centralCPU and programmed via a user program to IEC61131-3.In the “dual CPU” mode the user can access two separatelyprogrammable controllers with 40 inputs / outputseach. But the internal synchronised data interfacestill enables easy exchange between the separately runningapplication processes. The ExtendedControlleradditionally supports up to four CAN interfaces in thisoperating mode.Connectors and splitter boxesType Description Orderno.Connector AMP 55-polewirable, with contactsConnector wiredcable length 2.5 mConnector wiredcable length 1.2 mCable with connectorcores sealed individually, 1.2 mProgramming software CoDeSys+ tools, GermanProgramming software CoDeSys+ tools, EnglishEC2013EC2046EC2086EC2084CP9006CP9008Further accessories are available starting on page 139Further connectors and splitter boxes are availablestarting on page 129Mobile controllersClassic-ControllerExtended-ControllerSmart-ControllerSafety-ControllerCabinet-ControllerCoDeSyssoftwareand toolsStarter setControllersandsoftwarePage36 - 3940 - 4142 - 4344 - 4546 - 4748 - 4950 - 5140

Controllers and softwareExtendedController 16 bitCompact design with 80 inputs / outputsInputs /outputstotalInputsdigital /analogueInputs dig. /frequency(pos. / neg.)Inputsdigital(pos. / neg.)InputsdigitalOutputsdigital / PWM /curr.-controlledOutputsdigitalOutputsdigitalPWMFunctionH-bridgeWiringdiagramno.80 16 16 16 32 16 24 8 4 1 2 CR0200Drawingno.Orderno.DialoguemodulesGeneralinformationList of articlesI/O modulesMobilecontrollersApplication exampleBlock diagram (present twice in the device)Diagnosisand serviceV BBSV BBR5V3.3 VresetwatchdogSensorsfor mobileapplicationsV BBOCommon technical data55-pole connectiondigital OUTanalogue INdigital INTESTRS 232CAN 1CAN 216-bitμControllerRAM2x128kbytesFRAM32 kbytesFlash2048 kbytesclockaddressdecoderSignalconvertersConnectiontechnologyAccessoriesHousing: metalConnection: 55-pole AMP connectorTemperature range: -40...85 °CProtection rating: IP 67Ub: 10...32 V DCSwitching current outputs: 4 A / 2 AInterfaces: 4 x CAN 2.0, 2 x RS-232Program memory: 768 kB flashData memory: 128 kB SRAM, 128 kB flashData memory (non volatile): 17 kBCE, e1, appr. for railway applic. (EN 50155)Technicalinformationand customerserviceYou can find scale drawings from page 18041

Mobile controllersControllers and softwareSmartControllerUsable as intelligent I/O moduleor CANopen master.Gateway functions,CANopen, SAE J 1939.Configurable I/O functions.Freely programmableto IEC 61131-3.e1 type approval of the GermanFederal Office for Motor Traffic.SmartController 16 bitUniversal controllerIn small machines or applications where preprocessingof signals and data is required compact and very powerfulcontroller modules are used. The SmartControllerR360 has the required features. Depending on the configurationit can fulfil the different requirements.It can therefore be used as a compact controller. Theintegrated CANopen interface enables a flexible andpowerful extension of the system with further intelligentand standard I/O modules.If the two CAN interfaces are used, a freely programmableCAN gateway for coupling different networks isavailable which supports all important bus protocols.This enables an easy exchange of SAE J 1939 engine andCANopen data. Different transmission rates and thetransparent or preprocessing exchange of data betweennetworks are supported.Connectors and splitter boxesType Description Orderno.Connector AMP 55-polewirable, with contactsConnector wiredcable length 2.5 mConnector wiredcable length 1.2 mCable with connectorcores sealed individually, 1.2 mProgramming software CoDeSys+ tools, GermanProgramming software CoDeSys+ tools, EnglishEC2013EC2046EC2086EC2084CP9006CP9008Further accessories are available starting on page 139Further connectors and splitter boxes are availablestarting on page 129Mobile controllersClassic-ControllerExtended-ControllerSmart-ControllerSafety-ControllerCabinet-ControllerCoDeSyssoftwareand toolsStarter setControllersandsoftwarePage36 - 3940 - 4142 - 4344 - 4546 - 4748 - 4950 - 5142

Controllers and softwareSmartController 16 bitGateway functions for CANopen, SAE J 1939, ISO 11992 and ISO 11783Inputs /outputstotalInputsanalogue(V / I)Inputs dig. /frequency(pos. / neg.)Inputsdigital(pos. / neg.)Outputsdigital / PWM /curr.-controlledGatewayfunction2nd CANWiringdiagramno.8 4 2 2 4 SAE J 1939 4 3 CR2500Drawingno.Orderno.GeneralinformationList of articlesDialoguemodulesI/O modulesMobilecontrollersApplication exampleBlock diagramDiagnosisand service+U B5VresetwatchdogSensorsfor mobileapplications+U BclockCommon technical data55-pole connectiondigital OUTanalogue INdigital INTESTRS 232CAN 1CAN 216 BitμControllerRAM2x128kbytesflash1 Mbyteexternal CANcontrollerEEPROMaddressdecoderSignalconvertersConnectiontechnologyAccessoriesHousing: metalConnection: 55-pole AMP connectorTemperature range: -40...85 °CProtection rating: IP 67Ub: 10...32 V DCSwitching current outputs: 4 AInterfaces: 2 x CAN 2.0, 1 x RS-232Program memory: 192 kB flashData memory: 64 kB SRAM, 32 kB flashData memory (non volatile): 3 kBCE, e1, appr. for railway applic. (EN 50155)Technicalinformationand customerserviceYou can find scale drawings from page 18043

Mobile controllersControllers and softwareSafetyControllerSafety controller to IEC 61508 /EN 13849 safety category 3.Extended monitoring and testroutines for hardware and software.Freely programmableto IEC 61131-3.CAN interface with CANopenand CANopen safety protocol.e1 type approval of the GermanFederal Office for Motor Traffic.R360 SafetyController 16 bitSafety-related controllerFor control tasks with increased safety requirements theSafetyController R360 is available. Due to its integratedhardware and software function applications toIEC 61508 / EN 13849 can be controlled and monitored.Permanent checks of the CPU, memory and other hardwareby the operating system and extended diagnosticfunctions of the outputs enable a continuous monitoringof the control process. All important system informationfor the application program can be found in theeasy and clear programming system CoDeSys to IEC61131-3. Software tools enable safe and reliable loadingof the approved software for the machine productionas well.Via the CAN interface and CANopen protocol the SafetyControllercan be connected to further non safetyrelatedcontrollers or input / output modules of theR360 device family.Connectors and splitter boxesType Description Orderno.Connector AMP 55-polewirable, with contactsConnector wiredcable length 2.5 mConnector wiredcable length 1.2 mCable with connectorcores sealed individually, 1.2 mProgramming software CoDeSys+ tools, GermanProgramming software CoDeSys+ tools, EnglishEC2013EC2046EC2086EC2084CP9006CP9008Further accessories are available starting on page 139Further connectors and splitter boxes are availablestarting on page 129Mobile controllersClassic-ControllerExtended-ControllerSmart-ControllerSafety-ControllerCabinet-ControllerCoDeSyssoftwareand toolsStarter setControllersandsoftwarePage36 - 3940 - 4142 - 4344 - 4546 - 4748 - 4950 - 5144

Controllers and softwareR360 SafetyControllerAnalogue, digital, diagnostic and pulse inputsDigital, PWM or current-controlled outputs, H-bridge function (to IEC 61508 / EN 13849)Inputs /outputstotalInputsdigital /analogueInputs dig. /frequency(pos.)Inputsdigital(pos. / neg.)InputsdigitalOutputsdigital / PWM /curr.-controlledOutputsdigitalOutputsdigitalPWMFunctionH-bridgeWiringdiagramno.40 8 8 8 4 8 12 4 2 5 1 CR702024 8 8 – 4 8 – – – 6 1 CR750580 16 16 16 8 16 24 8 4 5 2 CR7200Drawingno.Orderno.DialoguemodulesGeneralinformationList of articlesI/O modulesMobilecontrollersApplication exampleBlock diagramDiagnosisand serviceV BBSV BBR5V3.3 VresetwatchdogSensorsfor mobileapplicationsV BBOCommon technical data55-pole connectiondigital OUTanalogue INdigital INTESTRS 232CAN 1CAN 216-bitμControllerRAM2x128kbytesFRAM32 kbytesFlash2048 kbytesclockaddressdecoderSignalconvertersConnectiontechnologyAccessoriesHousing: metalConnection: 55-pole AMP connectorTemperature range: -40...75 °CProtection rating: IP 67Ub: 10...32 V DCSwitching current outputs: 4 A / 2 AInterfaces: 2 x CAN 2.0, 1 x RS-232Program memory: 768 kB flashData memory: 128 kB SRAM, 128 kB flashData memory (non volatile): 17 kBCE, e1, appr. for railway applic. (EN 50155)Technicalinformationand customerserviceYou can find scale drawings from page 18045

Mobile controllersControllers and softwareCabinetControllerInputs for analogue, digital,diagnostic and pulse signals.Digital outputs designed as solidstateoutputs or potential-free relays.Usable as a controller for cockpitor operating panels.Freely programmableto IEC 61131-3.e1 type approval of the GermanFederal Office for Motor Traffic.CabinetController 16 bitSpace-saving control cabinet solutionFor large mobile machines cabins for operators are oftenused. In the environment around the driver's workplacemany signals, e.g. from switches, joysticks and signalindicators are generated. To ensure a low-cost connectionof these signals to the process controller, they arecollected at a central point, preprocessed and transferredvia CANopen.The CabinetController has been developed for thisapplication. Its flat design enables integration in dashboardsand operating panels. To connect the switches,<strong>sensors</strong> and actuators all important potentials arebrought out to the connectors. But the CabinetControlleris also used in small compact machines. Here thecontroller is often directly installed in a control cabinet.Therefore a high protection rating and robust housingare not required. All other important data of a mobilecontroller comply with those of the other controllersfrom the ecomat mobile family.Connectors and splitter boxesType Description Orderno.Plug set for CR0301, CR0302Plug set for CR0303RS-232 programming adapterfor CR0301, CR0302Cable with connectorAMP 6-pole, wired, 1.2 mCable with connectorAMP 10-pole, wired, 1.2 mCable with connectorAMP 14-pole, wired, 1.2 mCable with connectorAMP 18-pole, wired, 1.2 mEC2075EC2090EC2076EC1520EC1521EC1522EC1523Further accessories are available starting on page 139Further connectors and splitter boxes are availablestarting on page 129Mobile controllersClassic-ControllerExtended-ControllerSmart-ControllerSafety-ControllerCabinet-ControllerCoDeSyssoftwareand toolsStarter setControllersandsoftwarePage36 - 3940 - 4142 - 4344 - 4546 - 4748 - 4950 - 5146

Controllers and softwareR360 CabinetControllerIntegration in dashboards and operating panelsInputs /outputstotalInputs digital /analogue(V / I)Inputsdigital /frequencyInputsdigitalOutputsdigital /PWMOutputsrelayWiringdiagramno.Drawingno.42 8 / 8 4 / 4 8 / – 4 / 4 10 / – 7 4 CR030136 8 / 8 4 / 4 8 / – 4 / 8 – / – 8 5 CR030242 8 / 8 4 / 4 12 / 4 12 / 8 – / 6 9 6 CR0303Orderno.I/O modulesGeneralinformationList of articlesMobilecontrollersApplication exampleCable for CabinetControllerDialoguemodulesEC15206 polesEC152110 polesEC152214 polesEC152318 polesDiagnosisand serviceCR0301 12 –3CR030212–2CR0303 2 2–3Sensorsfor mobileapplicationsBlock diagram CR0301, CR0302Signalconvertersdigital OUT5VresetwatchdogConnectiontechnologyCommon technical dataCR0301, CR0302Housing: open with pottingConnectors.: 18-, 10-, 6-pole AMPTemperature range: -40...85 °CProtection rating: IP 20; Ub: 10...32 V DCSwitch. curr. output: PNP 2 A, relays 2/10 AInterfaces: 1 x CAN 2.0, 1 x RS232Program memory: 192 kB flashData memory: 64 kB SRAM, 32 kB flashData memory (non volatile): 3 kBCE, e1, appr. for railway applic. (EN 50155)except forCR 0302analogue INdigital INTESTRS 232CAN+U Bclock1 Amp+U B+U B16-bitμControllerRAM2x128kbytesFlash512 kbytesEEPROMaddressdecoderAccessoriesTechnicalinformationand customerserviceYou can find scale drawings from page 18047

Mobile controllersControllers and softwareCoDeSys software and toolsUsable on common Windows PCs.Easy networking of the devices withthe PC by means of the CAN bus.Standardised software interface withDDE or OLE technology.Powerful interfaces, e.g. for GPSdata or FTP transfer.User-friendly and easy to use.CoDeSys + toolsPowerful programming softwareThe importance of the software keeps increasing inmobile control technology as well. Therefore it is necessaryfor the user to have compatible and easy-to-useprograms for software creation, parameter setting andremote maintenance.The programming tool CoDeSys to IEC 61131-3 providesthe programmer with different program languages(FBD, LD, SFC, IL and ST) for fast project implementationand management. A powerful visualisation module forthe graphic representation of the machine and installationfunctions completes the package. Via the integratedtarget visualisation the drawn graphic elements canbe directly loaded to the graphic display PDM360.In addition to the programming tool, the software CANcomBasisstation provides a powerful PC tool for remotemonitoring and maintenance. It is also possible toexchange the application software in the networkedcontrollers via this interface.Connectors and splitter boxesType Description Orderno.CAN-PC interface CANview RS-232CAN-PC interface CANview USBEC2070EC2071Further accessories are available starting on page 139Further connectors and splitter boxes are availablestarting on page 129Mobile controllersClassic-ControllerExtended-ControllerSmart-ControllerSafety-ControllerCabinet-ControllerCoDeSyssoftwareand toolsStarter setControllersandsoftwarePage36 - 3940 - 4142 - 4344 - 4546 - 4748 - 4950 - 5148

Controllers and softwareCoDeSys programming and diagnostic softwareSoftware tools for the ecomatmobile systemVersionCoDeSysLanguageUse forR 360Use forPDM 360ProgramminginterfaceData carrier2.3 German yes yes RS-232, CAN, Ethernet CD-ROM CP90062.3 English yes yes RS-232, CAN, Ethernet CD-ROM CP9008Orderno.GeneralinformationDialoguemodulesI/O modulesMobilecontrollersList of articlesCD structureScreenshotTechnicalinformationand customerserviceAccessoriesDiagnosisand serviceConnectiontechnologySignalconvertersSensorsfor mobileapplicationsYou can find scale drawings from page 18049

Mobile controllersControllers and softwareStarter setEasy system introduction.Wired hardware components.Integrated simulator for analogueand digital signals.Two CAN interfaces to test allCAN / gateway functions.Programming system, examplesand documentation on CD-ROM.R360 starter setComplete set for learning and testing.If you have no experience with programming via CoDe-Sys, the R360 starter set gives you an easy and convenientintroduction to the R360 controller hardware andto the different CoDeSys programming languages. Thepackage contains all the required hardware components– from the controller, power supply to the completecable harness with integrated simulator for input andoutput signals. The required programming software,documentation and other tools are contained on theenclosed CD. The printed brief instructions allow easyand successful introduction to the first project with theR360 starter set.But the starter set also offers many advantages for theexperienced programmer. Program parts can be developed,tested and optimised without much input irrespectiveof the overall application. The CAN interfacesbrought out from the cable harness enable developmentand optimisation of network programs.Connectors and splitter boxesType Description Orderno.Spring terminal boxEC2032Further accessories are available starting on page 139Further connectors and splitter boxes are availablestarting on page 129Mobile controllersClassic-ControllerExtended-ControllerSmart-ControllerSafety-ControllerCabinet-ControllerCoDeSyssoftwareand toolsStarter setControllersandsoftwarePage36 - 3940 - 4142 - 4344 - 4546 - 4748 - 4950 - 5150