Air Quality Control Systems and Components - Hitachi Power ...

Air Quality Control Systems and Components - Hitachi Power ...

Air Quality Control Systems and Components - Hitachi Power ...

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

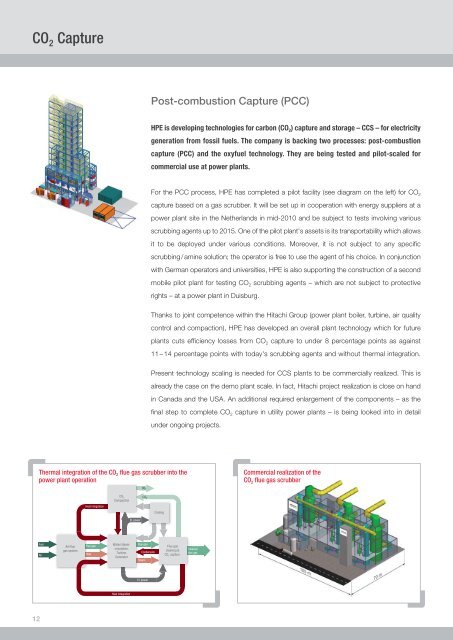

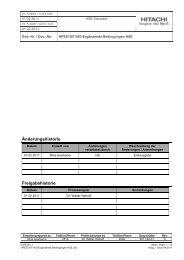

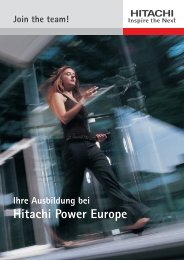

CO 2 CapturePost-combustion Capture (PCC)HPE is developing technologies for carbon (CO 2 ) capture <strong>and</strong> storage – CCS – for electricitygeneration from fossil fuels. The company is backing two processes: post-combustioncapture (PCC) <strong>and</strong> the oxyfuel technology. They are being tested <strong>and</strong> pilot-scaled forcommercial use at power plants.For the PCC process, HPE has completed a pilot facility (see diagram on the left) for CO 2capture based on a gas scrubber. It will be set up in cooperation with energy suppliers at apower plant site in the Netherl<strong>and</strong>s in mid-2010 <strong>and</strong> be subject to tests involving variousscrubbing agents up to 2015. One of the pilot plant's assets is its transportability which allowsit to be deployed under various conditions. Moreover, it is not subject to any specificscrubbing / amine solution; the operator is free to use the agent of his choice. In conjunctionwith German operators <strong>and</strong> universities, HPE is also supporting the construction of a secondmobile pilot plant for testing CO 2 scrubbing agents – which are not subject to protectiverights – at a power plant in Duisburg.Thanks to joint competence within the <strong>Hitachi</strong> Group (power plant boiler, turbine, air qualitycontrol <strong>and</strong> compaction), HPE has developed an overall plant technology which for futureplants cuts efficiency losses from CO 2 capture to under 8 percentage points as against11 – 14 percentage points with today's scrubbing agents <strong>and</strong> without thermal integration.Present technology scaling is needed for CCS plants to be commercially realized. This isalready the case on the demo plant scale. In fact, <strong>Hitachi</strong> project realization is close on h<strong>and</strong>in Canada <strong>and</strong> the USA. An additional required enlargement of the components – as thefinal step to complete CO 2 capture in utility power plants – is being looked into in detailunder ongoing projects.Thermal integration of the CO 2 flue gas scrubber into thepower plant operationCommercial realization of theCO 2 flue gas scrubberCO 2CO 2CompactionCO 2Heat integrationCoolingEl. powerFuel<strong>Air</strong><strong>Air</strong>/fluegas systemFlue gasHeatWater/steamcirculation,Turbine,GeneratorFlue gasCondensateSteamFlue gascleaning &CO 2 captureCleanedflue gasEl. power105 m70 mHeat integration12