Air Quality Control Systems and Components - Hitachi Power ...

Air Quality Control Systems and Components - Hitachi Power ...

Air Quality Control Systems and Components - Hitachi Power ...

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

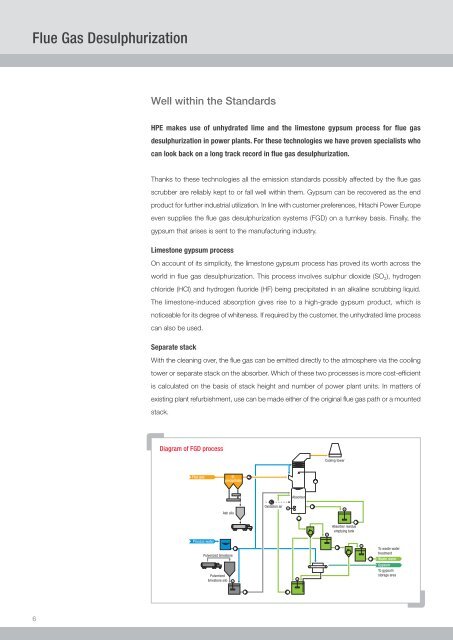

Flue Gas DesulphurizationWell within the St<strong>and</strong>ardsHPE makes use of unhydrated lime <strong>and</strong> the limestone gypsum process for flue gasdesulphurization in power plants. For these technologies we have proven specialists whocan look back on a long track record in flue gas desulphurization.Thanks to these technologies all the emission st<strong>and</strong>ards possibly affected by the flue gasscrubber are reliably kept to or fall well within them. Gypsum can be recovered as the endproduct for further industrial utilization. In line with customer preferences, <strong>Hitachi</strong> <strong>Power</strong> Europeeven supplies the flue gas desulphurization systems (FGD) on a turnkey basis. Finally, thegypsum that arises is sent to the manufacturing industry.Limestone gypsum processOn account of its simplicity, the limestone gypsum process has proved its worth across theworld in flue gas desulphurization. This process involves sulphur dioxide (SO 2 ), hydrogenchloride (HCl) <strong>and</strong> hydrogen fluoride (HF) being precipitated in an alkaline scrubbing liquid.The limestone-induced absorption gives rise to a high-grade gypsum product, which isnoticeable for its degree of whiteness. If required by the customer, the unhydrated lime processcan also be used.Separate stackWith the cleaning over, the flue gas can be emitted directly to the atmosphere via the coolingtower or separate stack on the absorber. Which of these two processes is more cost-efficientis calculated on the basis of stack height <strong>and</strong> number of power plant units. In matters ofexisting plant refurbishment, use can be made either of the original flue gas path or a mountedstack.Diagram of FGD processCooling towerFlue gasEl.precipitatorAbsorberAsh siloOxidation airAbsorber residueemptying tankProcess waterPulverized limestonePulverizedlimestone siloTo waste watertreatmentWaste waterGypsumTo gypsumstorage area6