Air Quality Control Systems and Components - Hitachi Power ...

Air Quality Control Systems and Components - Hitachi Power ...

Air Quality Control Systems and Components - Hitachi Power ...

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

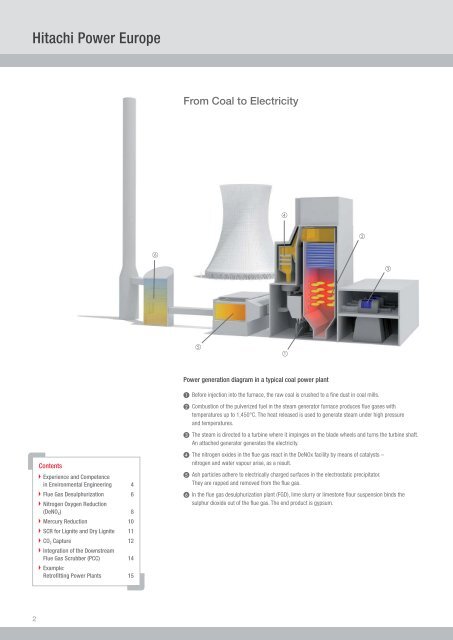

<strong>Hitachi</strong> <strong>Power</strong> EuropeFrom Coal to Electricity<strong>Power</strong> generation diagram in a typical coal power plant Before injection into the furnace, the raw coal is crushed to a fine dust in coal mills. Combustion of the pulverized fuel in the steam generator furnace produces flue gases withtemperatures up to 1,450°C. The heat released is used to generate steam under high pressure<strong>and</strong> temperatures. The steam is directed to a turbine where it impinges on the blade wheels <strong>and</strong> turns the turbine shaft.An attached generator generates the electricity.ContentsExperience <strong>and</strong> Competencein Environmental Engineering 4Flue Gas Desulphurization 6Nitrogen Oxygen Reduction(DeNO X ) 8Mercury Reduction 10SCR for Lignite <strong>and</strong> Dry Lignite 11CO 2 Capture 12Integration of the DownstreamFlue Gas Scrubber (PCC) 14Example:Retrofitting <strong>Power</strong> Plants 15 The nitrogen oxides in the flue gas react in the DeNOx facility by means of catalysts –nitrogen <strong>and</strong> water vapour arise, as a result. Ash particles adhere to electrically charged surfaces in the electrostatic precipitator.They are rapped <strong>and</strong> removed from the flue gas. In the flue gas desulphurization plant (FGD), lime slurry or limestone flour suspension binds thesulphur dioxide out of the flue gas. The end product is gypsum.2