Air Quality Control Systems and Components - Hitachi Power ...

Air Quality Control Systems and Components - Hitachi Power ...

Air Quality Control Systems and Components - Hitachi Power ...

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

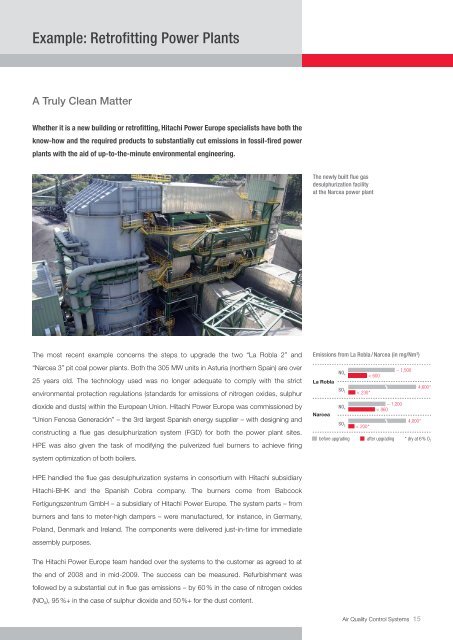

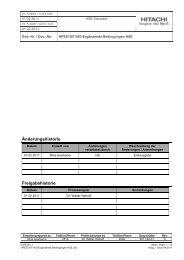

Example: Retrofitting <strong>Power</strong> PlantsA Truly Clean MatterWhether it is a new building or retrofitting, <strong>Hitachi</strong> <strong>Power</strong> Europe specialists have both theknow-how <strong>and</strong> the required products to substantially cut emissions in fossil-fired powerplants with the aid of up-to-the-minute environmental engineering.The newly built flue gasdesulphurization facilityat the Narcea power plantThe most recent example concerns the steps to upgrade the two “La Robla 2” <strong>and</strong>“Narcea 3” pit coal power plants. Both the 305 MW units in Asturia (northern Spain) are over25 years old. The technology used was no longer adequate to comply with the strictenvironmental protection regulations (st<strong>and</strong>ards for emissions of nitrogen oxides, sulphurdioxide <strong>and</strong> dusts) within the European Union. <strong>Hitachi</strong> <strong>Power</strong> Europe was commissioned by“Union Fenosa Generación” – the 3rd largest Spanish energy supplier – with designing <strong>and</strong>constructing a flue gas desulphurization system (FGD) for both the power plant sites.HPE was also given the task of modifying the pulverized fuel burners to achieve firingsystem optimization of both boilers.Emissions from La Robla / Narcea (in mg/Nm 3 )La RoblaNarceaNO xSO 2 < 230*< 600NO x~ 1,200< 860~ 1,500SO 24,000*< 200*4,600*before upgrading after upgrading * dry at 6% O 2HPE h<strong>and</strong>led the flue gas desulphurization systems in consortium with <strong>Hitachi</strong> subsidiary<strong>Hitachi</strong>-BHK <strong>and</strong> the Spanish Cobra company. The burners come from BabcockFertigungszentrum GmbH – a subsidiary of <strong>Hitachi</strong> <strong>Power</strong> Europe. The system parts – fromburners <strong>and</strong> fans to meter-high dampers – were manufactured, for instance, in Germany,Pol<strong>and</strong>, Denmark <strong>and</strong> Irel<strong>and</strong>. The components were delivered just-in-time for immediateassembly purposes.The <strong>Hitachi</strong> <strong>Power</strong> Europe team h<strong>and</strong>ed over the systems to the customer as agreed to atthe end of 2008 <strong>and</strong> in mid-2009. The success can be measured. Refurbishment wasfollowed by a substantial cut in flue gas emissions – by 60 % in the case of nitrogen oxides(NO X ), 95 %+ in the case of sulphur dioxide <strong>and</strong> 50 %+ for the dust content.<strong>Air</strong> <strong>Quality</strong> <strong>Control</strong> <strong>Systems</strong> 15