91430 SPS cover edited - Electronic Fasteners Inc

91430 SPS cover edited - Electronic Fasteners Inc

91430 SPS cover edited - Electronic Fasteners Inc

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

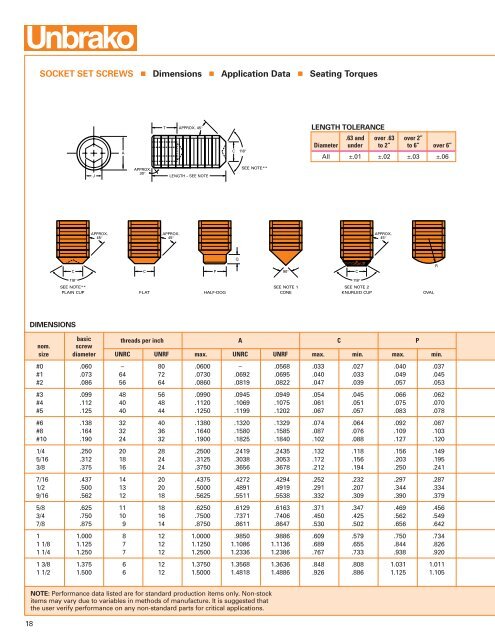

SOCKET SET SCREWS Dimensions Application Data Seating TorquesTAPPROX. 45°LENGTH TOLERANCEAC118°.63 and over .63 over 2”Diameter under to 2” to 6” over 6”All ±.01 ±.02 ±.03 ±.06JAPPROX.30°LENGTH – SEE NOTESEE NOTE**APPROX.45°APPROX.45°APPROX.45°QCCP90° CR118°118°SEE NOTE**PLAIN CUPFLATHALF-DOGSEE NOTE 1CONESEE NOTE 2KNURLED CUPOVALDIMENSIONSbasicnom. screwthreads per inch A C Psize diameter UNRC UNRF max. UNRC UNRF max. min. max. min.#0 .060 – 80 .0600 – .0568 .033 .027 .040 .037#1 .073 64 72 .0730 .0692 .0695 .040 .033 .049 .045#2 .086 56 64 .0860 .0819 .0822 .047 .039 .057 .053#3 .099 48 56 .0990 .0945 .0949 .054 .045 .066 .062#4 .112 40 48 .1120 .1069 .1075 .061 .051 .075 .070#5 .125 40 44 .1250 .1199 .1202 .067 .057 .083 .078#6 .138 32 40 .1380 .1320 .1329 .074 .064 .092 .087#8 .164 32 36 .1640 .1580 .1585 .087 .076 .109 .103#10 .190 24 32 .1900 .1825 .1840 .102 .088 .127 .1201/4 .250 20 28 .2500 .2419 .2435 .132 .118 .156 .1495/16 .312 18 24 .3125 .3038 .3053 .172 .156 .203 .1953/8 .375 16 24 .3750 .3656 .3678 .212 .194 .250 .2417/16 .437 14 20 .4375 .4272 .4294 .252 .232 .297 .2871/2 .500 13 20 .5000 .4891 .4919 .291 .207 .344 .3349/16 .562 12 18 .5625 .5511 .5538 .332 .309 .390 .3795/8 .625 11 18 .6250 .6129 .6163 .371 .347 .469 .4563/4 .750 10 16 .7500 .7371 .7406 .450 .425 .562 .5497/8 .875 9 14 .8750 .8611 .8647 .530 .502 .656 .6421 1.000 8 12 1.0000 .9850 .9886 .609 .579 .750 .7341 1/8 1.125 7 12 1.1250 1.1086 1.1136 .689 .655 .844 .8261 1/4 1.250 7 12 1.2500 1.2336 1.2386 .767 .733 .938 .9201 3/8 1.375 6 12 1.3750 1.3568 1.3636 .848 .808 1.031 1.0111 1/2 1.500 6 12 1.5000 1.4818 1.4886 .926 .886 1.125 1.105NOTE: Performance data listed are for standard production items only. Non-stockitems may vary due to variables in methods of manufacture. It is suggested thatthe user verify performance on any non-standard parts for critical applications.18