91430 SPS cover edited - Electronic Fasteners Inc

91430 SPS cover edited - Electronic Fasteners Inc

91430 SPS cover edited - Electronic Fasteners Inc

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

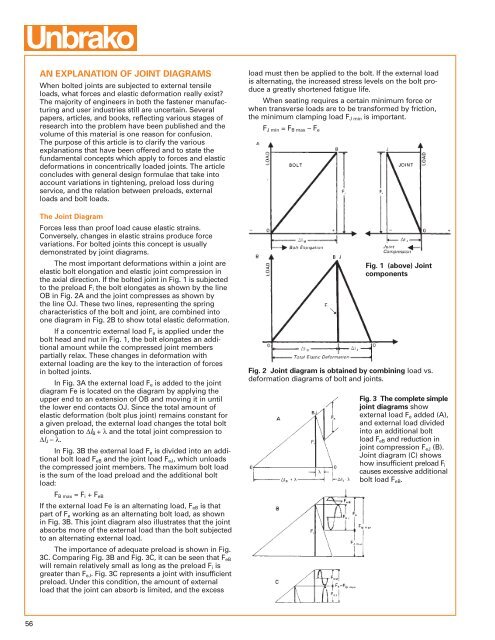

AN EXPLANATION OF JOINT DIAGRAMSWhen bolted joints are subjected to external tensileloads, what forces and elastic deformation really exist?The majority of engineers in both the fastener manufacturingand user industries still are uncertain. Severalpapers, articles, and books, reflecting various stages ofresearch into the problem have been published and thevolume of this material is one reason for confusion.The purpose of this article is to clarify the variousexplanations that have been offered and to state thefundamental concepts which apply to forces and elasticdeformations in concentrically loaded joints. The articleconcludes with general design formulae that take intoaccount variations in tightening, preload loss duringservice, and the relation between preloads, externalloads and bolt loads.The Joint DiagramForces less than proof load cause elastic strains.Conversely, changes in elastic strains produce forcevariations. For bolted joints this concept is usuallydemonstrated by joint diagrams.The most important deformations within a joint areelastic bolt elongation and elastic joint compression inthe axial direction. If the bolted joint in Fig. 1 is subjectedto the preload F i the bolt elongates as shown by the lineOB in Fig. 2A and the joint compresses as shown bythe line OJ. These two lines, representing the springcharacteristics of the bolt and joint, are combined intoone diagram in Fig. 2B to show total elastic deformation.If a concentric external load F e is applied under thebolt head and nut in Fig. 1, the bolt elongates an additionalamount while the compressed joint memberspartially relax. These changes in deformation withexternal loading are the key to the interaction of forcesin bolted joints.In Fig. 3A the external load F e is added to the jointdiagram Fe is located on the diagram by applying theupper end to an extension of OB and moving it in untilthe lower end contacts OJ. Since the total amount ofelastic deformation (bolt plus joint) remains constant fora given preload, the external load changes the total boltelongation to ∆l B + λ and the total joint compression to∆l J – λ.In Fig. 3B the external load F e is divided into an additionalbolt load F eB and the joint load F eJ , which unloadsthe compressed joint members. The maximum bolt loadis the sum of the load preload and the additional boltload:load must then be applied to the bolt. If the external loadis alternating, the increased stress levels on the bolt producea greatly shortened fatigue life.When seating requires a certain minimum force orwhen transverse loads are to be transformed by friction,the minimum clamping load F J min is important.F J min = F B max – F eFig. 1 (above) JointcomponentsFig. 2 Joint diagram is obtained by combining load vs.deformation diagrams of bolt and joints.Fig. 3 The complete simplejoint diagrams showexternal load F e added (A),and external load dividedinto an additional boltload F eB and reduction injoint compression F eJ (B).Joint diagram (C) showshow insufficient preload F icauses excessive additionalbolt load F eB .F B max = F i + F eBIf the external load Fe is an alternating load, F eB is thatpart of F e working as an alternating bolt load, as shownin Fig. 3B. This joint diagram also illustrates that the jointabsorbs more of the external load than the bolt subjectedto an alternating external load.The importance of adequate preload is shown in Fig.3C. Comparing Fig. 3B and Fig. 3C, it can be seen that F eBwill remain relatively small as long as the preload F i isgreater than F eJ . Fig. 3C represents a joint with insufficientpreload. Under this condition, the amount of externalload that the joint can absorb is limited, and the excess56