The complete issue (pdf format/28 pages) - ST Electronics

The complete issue (pdf format/28 pages) - ST Electronics

The complete issue (pdf format/28 pages) - ST Electronics

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

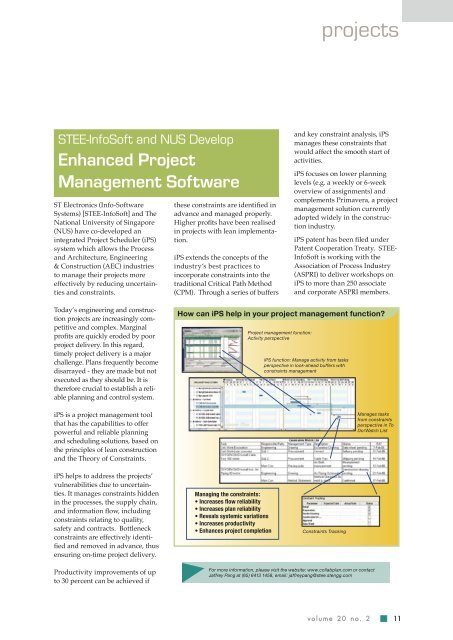

projects<strong>ST</strong>EE-InfoSoft and NUS DevelopEnhanced ProjectManagement Software<strong>ST</strong> <strong>Electronics</strong> (Info-SoftwareSystems) [<strong>ST</strong>EE-InfoSoft] and <strong>The</strong>National University of Singapore(NUS) have co-developed anintegrated Project Scheduler (iPS)system which allows the Processand Architecture, Engineering& Construction (AEC) industriesto manage their projects moreeffectively by reducing uncertaintiesand constraints.these constraints are identified inadvance and managed properly.Higher profits have been realisedin projects with lean implementation.iPS extends the concepts of theindustry’s best practices toincorporate constraints into thetraditional Critical Path Method(CPM). Through a series of buffersand key constraint analysis, iPSmanages these constraints thatwould affect the smooth start ofactivities.iPS focuses on lower planninglevels (e.g. a weekly or 6-weekoverview of assignments) andcomplements Primavera, a projectmanagement solution currentlyadopted widely in the constructionindustry.iPS patent has been filed underPatent Cooperation Treaty. <strong>ST</strong>EE-InfoSoft is working with theAssociation of Process Industry(ASPRI) to deliver workshops oniPS to more than 250 associateand corporate ASPRI members.Today’s engineering and constructionprojects are increasingly competitiveand complex. Marginalprofits are quickly eroded by poorproject delivery. In this regard,timely project delivery is a majorchallenge. Plans frequently becomedisarrayed - they are made but notexecuted as they should be. It istherefore crucial to establish a reliableplanning and control system.iPS is a project management toolthat has the capabilities to offerpowerful and reliable planningand scheduling solutions, based onthe principles of lean constructionand the <strong>The</strong>ory of Constraints.How can iPS help in your project management function?Project management function:Activity perspectiveiPS function: Manage activity from tasksperspective in look-ahead buffers withconstraints managementManages tasksfrom constraintsperspective in ToDo/Watch ListiPS helps to address the projects’vulnerabilities due to uncertainties.It manages constraints hiddenin the processes, the supply chain,and in<strong>format</strong>ion flow, includingconstraints relating to quality,safety and contracts. Bottleneckconstraints are effectively identifiedand removed in advance, thusensuring on-time project delivery.Managing the constraints:• Increases flow reliability• Increases plan reliability• Reveals systemic variations• Increases productivity• Enhances project completionConstraints TrackingProductivity improvements of upto 30 percent can be achieved ifFor more in<strong>format</strong>ion, please visit the website: www.collabplan.com or contactJaffrey Pang at (65) 6413 1458, email: jaffreypang@stee.stengg.comvolume 20 no. 2 11

![The complete issue [ 32 pages | 2.43 MB ] - ST Electronics](https://img.yumpu.com/47270333/1/184x260/the-complete-issue-32-pages-243-mb-st-electronics.jpg?quality=85)