fem modelling of a bellows and a bellows- based micromanipulator

fem modelling of a bellows and a bellows- based micromanipulator

fem modelling of a bellows and a bellows- based micromanipulator

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

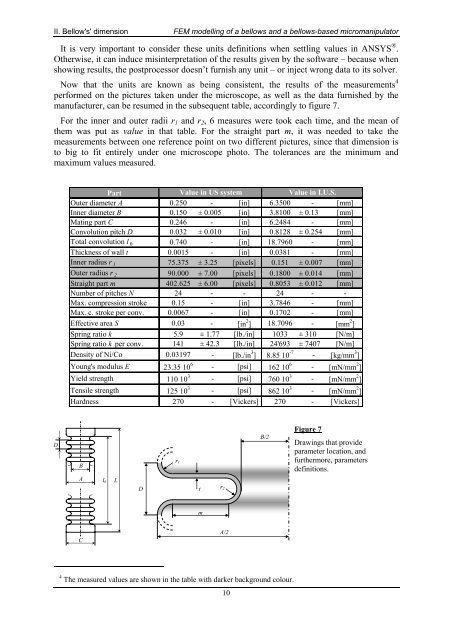

II. Bellow's' dimensionFEM <strong>modelling</strong> <strong>of</strong> a <strong>bellows</strong> <strong>and</strong> a <strong>bellows</strong>-<strong>based</strong> <strong>micromanipulator</strong>It is very important to consider these units definitions when settling values in ANSYS ® .Otherwise, it can induce misinterpretation <strong>of</strong> the results given by the s<strong>of</strong>tware – because whenshowing results, the postprocessor doesn’t furnish any unit – or inject wrong data to its solver.Now that the units are known as being consistent, the results <strong>of</strong> the measurements 4performed on the pictures taken under the microscope, as well as the data furnished by themanufacturer, can be resumed in the subsequent table, accordingly to figure 7.For the inner <strong>and</strong> outer radii r 1 <strong>and</strong> r 2 , 6 measures were took each time, <strong>and</strong> the mean <strong>of</strong>them was put as value in that table. For the straight part m, it was needed to take themeasurements between one reference point on two different pictures, since that dimension isto big to fit entirely under one microscope photo. The tolerances are the minimum <strong>and</strong>maximum values measured.PartValue in US systemValue in I.U.S.Outer diameter A 0.250 - [in] 6.3500 - [mm]Inner diameter B 0.150 ± 0.005 [in] 3.8100 ± 0.13 [mm]Mating part C 0.246 - [in] 6.2484 - [mm]Convolution pitch D 0.032 ± 0.010 [in] 0.8128 ± 0.254 [mm]Total convolution l 0 0.740 - [in] 18.7960 - [mm]Thickness <strong>of</strong> wall t 0.0015 - [in] 0.0381 - [mm]Inner radius r 1 75.375 ± 3.25 [pixels] 0.151 ± 0.007 [mm]Outer radius r 2 90.000 ± 7.00 [pixels] 0.1800 ± 0.014 [mm]Straight part m 402.625 ± 6.00 [pixels] 0.8053 ± 0.012 [mm]Number <strong>of</strong> pitches N 24 - - 24 - -Max. compression stroke 0.15 - [in] 3.7846 - [mm]Max. c. stroke per conv. 0.0067 - [in] 0.1702 - [mm]Effective area S 0.03 - [in 2 ] 18.7096 - [mm 2 ]Spring ratio k 5.9 ± 1.77 [lb./in] 1033 ± 310 [N/m]Spring ratio k per conv. 141 ± 42.3 [lb./in] 24'693 ± 7407 [N/m]Density <strong>of</strong> Ni/Co 0.03197 - [lb./in 3 ] 8.85 10 -7 - [kg/mm 3 ]Young's modulus E 23.35 10 6 - [psi] 162 10 6 - [mN/mm 2 ]Yield strength 110 10 3 - [psi] 760 10 3 - [mN/mm 2 ]Tensile strength 125 10 3 - [psi] 862 10 3 - [mN/mm 2 ]Hardness 270 - [Vickers] 270 - [Vickers]DBAl 0LDr 1r 2tB/2Figure 7Drawings that provideparameter location, <strong>and</strong>furthermore, parametersdefinitions.mCA/24 The measured values are shown in the table with darker background colour.10