Heater Catalog (Section) - Immersion Heaters - Watlow

Heater Catalog (Section) - Immersion Heaters - Watlow

Heater Catalog (Section) - Immersion Heaters - Watlow

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

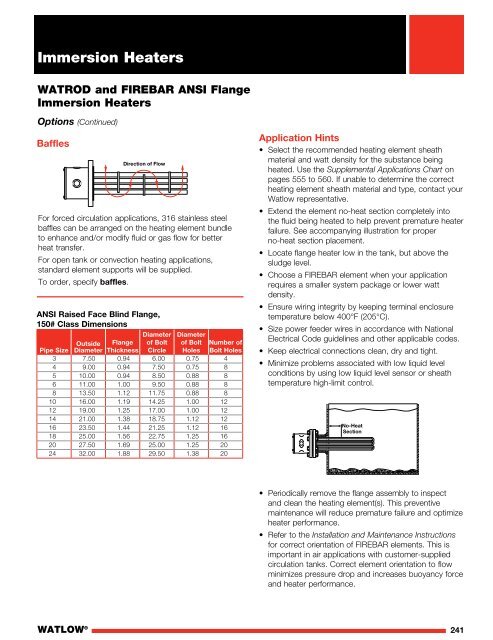

Direction of Flow<strong>Immersion</strong> <strong>Heater</strong>sWATROD and FIREBAR ANSI Flange<strong>Immersion</strong> <strong>Heater</strong>sOptions (Continued)BafflesDirection of FlowFor forced circulation applications, 316 stainless steelbaffles can be arranged on the heating element bundleto enhance and/or modify fluid or gas flow for betterheat transfer.For open tank or convection heating applications,standard element supports will be supplied.To order, specify baffles.ANSI Raised Face Blind Flange,150# Class DimensionsPipe SizeDiameterof BoltCircleDiameterof BoltHolesOutsideDiameterFlangeThickness3 7.50 0.94 6.00 0.75 44 9.00 0.94 7.50 0.75 85 10.00 0.94 8.50 0.88 86 11.00 1.00 9.50 0.88 88 13.50 1.12 11.75 0.88 810 16.00 1.19 14.25 1.00 1212 19.00 1.25 17.00 1.00 1214 21.00 1.38 18.75 1.12 1216 23.50 1.44 21.25 1.12 1618 25.00 1.56 22.75 1.25 1620 27.50 1.69 25.00 1.25 2024 32.00 1.88 29.50 1.38 20Number ofBolt HolesApplication Hints• Select the recommended heating element sheathmaterial and watt density for the substance beingheated. Use the Supplemental Applications Chart onpages 555 to 560. If unable to determine the correctheating element sheath material and type, contact your<strong>Watlow</strong> representative.• Extend the element no-heat section completely intothe fluid being heated to help prevent premature heaterfailure. See accompanying illustration for properno-heat section placement.• Locate flange heater low in the tank, but above thesludge level.• Choose a FIREBAR element when your applicationrequires a smaller system package or lower wattdensity.• Ensure wiring integrity by keeping terminal enclosuretemperature below 400°F (205°C).• Size power feeder wires in accordance with NationalElectrical Code guidelines and other applicable codes.• Keep electrical connections clean, dry and tight.• Minimize problems associated with low liquid levelconditions by using low liquid level sensor or sheathtemperature high-limit control.No-Heat<strong>Section</strong>• Periodically remove the flange assembly to inspectand clean the heating element(s). This preventivemaintenance will reduce premature failure and optimizeheater performance.• Refer to the Installation and Maintenance Instructionsfor correct orientation of FIREBAR elements. This isimportant in air applications with customer-suppliedcirculation tanks. Correct element orientation to flowminimizes pressure drop and increases buoyancy forceand heater performance.WATLOW ®241