Miller AL4 Series

Miller AL4 Series

Miller AL4 Series

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

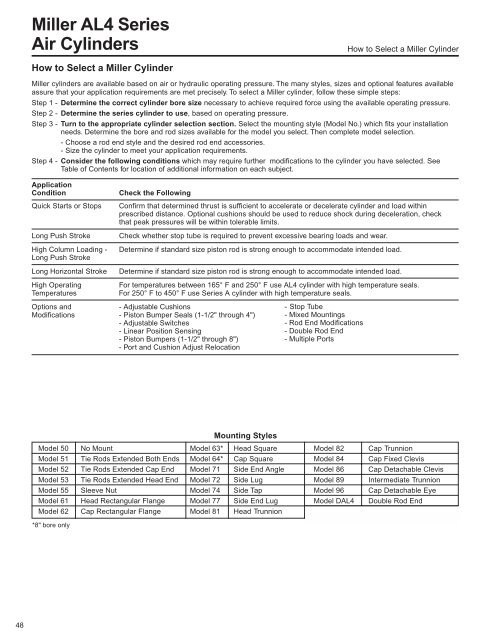

<strong>Miller</strong> <strong>AL4</strong> <strong>Series</strong>Air CylindersHow to Select a <strong>Miller</strong> CylinderHow to Select a <strong>Miller</strong> Cylinder<strong>Miller</strong> cylinders are available based on air or hydraulic operating pressure. The many styles, sizes and optional features availableassure that your application requirements are met precisely. To select a <strong>Miller</strong> cylinder, follow these simple steps:Step 1 - Determine the correct cylinder bore size necessary to achieve required force using the available operating pressure.Step 2 - Determine the series cylinder to use, based on operating pressure.Step 3 - Turn to the appropriate cylinder selection section. Select the mounting style (Model No.) which fits your installationneeds. Determine the bore and rod sizes available for the model you select. Then complete model selection.- Choose a rod end style and the desired rod end accessories.- Size the cylinder to meet your application requirements.Step 4 - Consider the following conditions which may require further modifications to the cylinder you have selected. SeeTable of Contents for location of additional information on each subject.ApplicationConditionQuick Starts or StopsLong Push StrokeHigh Column Loading -Long Push StrokeLong Horizontal StrokeHigh OperatingTemperaturesCheck the FollowingConfirm that determined thrust is sufficient to accelerate or decelerate cylinder and load withinprescribed distance. Optional cushions should be used to reduce shock during deceleration, checkthat peak pressures will be within tolerable limits.Check whether stop tube is required to prevent excessive bearing loads and wear.Determine if standard size piston rod is strong enough to accommodate intended load.Determine if standard size piston rod is strong enough to accommodate intended load.For temperatures between 165° F and 250° F use <strong>AL4</strong> cylinder with high temperature seals.For 250° F to 450° F use <strong>Series</strong> A cylinder with high temperature seals.Options and- Adjustable CushionsModifications - Piston Bumper Seals (1-1/2" through 4")- Adjustable Switches- Linear Position Sensing- Piston Bumpers (1-1/2" through 8")- Port and Cushion Adjust Relocation- Stop Tube- Mixed Mountings- Rod End Modifications- Double Rod End- Multiple PortsMounting StylesModel 50 No Mount Model 63* Head Square Model 82 Cap TrunnionModel 51 Tie Rods Extended Both Ends Model 64* Cap Square Model 84 Cap Fixed ClevisModel 52 Tie Rods Extended Cap End Model 71 Side End Angle Model 86 Cap Detachable ClevisModel 53 Tie Rods Extended Head End Model 72 Side Lug Model 89 Intermediate TrunnionModel 55 Sleeve Nut Model 74 Side Tap Model 96 Cap Detachable EyeModel 61 Head Rectangular Flange Model 77 Side End Lug Model D<strong>AL4</strong> Double Rod EndModel 62 Cap Rectangular Flange Model 81 Head Trunnion*8" bore only48