Miller AL4 Series

Miller AL4 Series

Miller AL4 Series

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

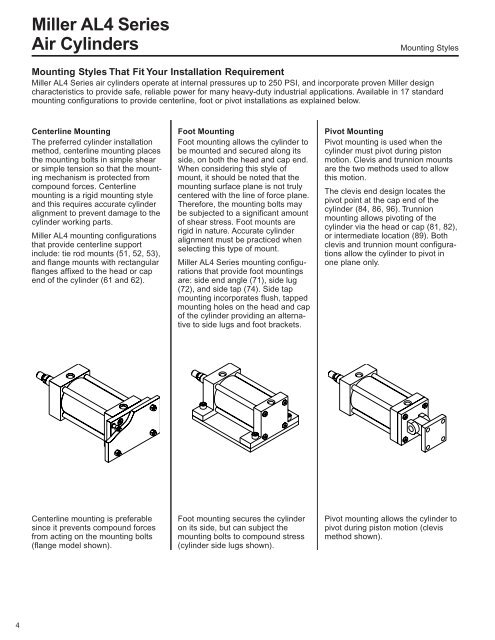

<strong>Miller</strong> <strong>AL4</strong> <strong>Series</strong>Air CylindersMounting StylesMounting Styles That Fit Your Installation Requirement<strong>Miller</strong> <strong>AL4</strong> <strong>Series</strong> air cylinders operate at internal pressures up to 250 PSI, and incorporate proven <strong>Miller</strong> designcharacteristics to provide safe, reliable power for many heavy-duty industrial applications. Available in 17 standardmounting configurations to provide centerline, foot or pivot installations as explained below.Centerline MountingThe preferred cylinder installationmethod, centerline mounting placesthe mounting bolts in simple shearor simple tension so that the mountingmechanism is protected fromcompound forces. Centerlinemounting is a rigid mounting styleand this requires accurate cylinderalignment to prevent damage to thecylinder working parts.<strong>Miller</strong> <strong>AL4</strong> mounting configurationsthat provide centerline supportinclude: tie rod mounts (51, 52, 53),and flange mounts with rectangularflanges affixed to the head or capend of the cylinder (61 and 62).Foot MountingFoot mounting allows the cylinder tobe mounted and secured along itsside, on both the head and cap end.When considering this style ofmount, it should be noted that themounting surface plane is not trulycentered with the line of force plane.Therefore, the mounting bolts maybe subjected to a significant amountof shear stress. Foot mounts arerigid in nature. Accurate cylinderalignment must be practiced whenselecting this type of mount.<strong>Miller</strong> <strong>AL4</strong> <strong>Series</strong> mounting configurationsthat provide foot mountingsare: side end angle (71), side lug(72), and side tap (74). Side tapmounting incorporates flush, tappedmounting holes on the head and capof the cylinder providing an alternativeto side lugs and foot brackets.Pivot MountingPivot mounting is used when thecylinder must pivot during pistonmotion. Clevis and trunnion mountsare the two methods used to allowthis motion.The clevis end design locates thepivot point at the cap end of thecylinder (84, 86, 96). Trunnionmounting allows pivoting of thecylinder via the head or cap (81, 82),or intermediate location (89). Bothclevis and trunnion mount configurationsallow the cylinder to pivot inone plane only.Centerline mounting is preferablesince it prevents compound forcesfrom acting on the mounting bolts(flange model shown).Foot mounting secures the cylinderon its side, but can subject themounting bolts to compound stress(cylinder side lugs shown).Pivot mounting allows the cylinder topivot during piston motion (clevismethod shown).4