ASM Science Journal, Volume 7(1), 2013ACKNOWLEDGEMENTSThe authors would like to thank the Institute ofMicroengineering and Nanoelectronics and UniversitiKebangsaan <strong>Malaysia</strong> for the support and facilities.Date of submission: May 2011Date of acceptance: November 2012REFERENCESAtta, RMH, 2004, ‘Multi-layer double coil micro-fabricatedtransformer’, Sensors and Actuators A, vol. 103, pp. 61–65.Baschirotto, A, Dallago, E, Malcovati, P, Marchesi, M &Venchi, G, 2007, ‘A fluxgate magnetic sensor: from PCBto micro-integrated technology', IEEE Transactions onInstrumentation and Measurement 1, vol. 56, pp. 25–31.Dezuari, O, Belloy, E, Gilbert, SE & Gijs, AM, 1999, ‘Newhybrid technology for planar fluxgate sensor fabrication’,IEEE Transactions on Magnetics 4, vol. 35, pp. 2111–2117.Lei, C, Wang, R, Zhou, Y & Zhou, Z, 2009, ‘MEMS microfluxgate sensors with mutual vertical excitation coilsand detection coils’, Microsyst. Technol., vol. 15, pp. 969–972.Liakopoulos, TM & Ahn, CH, 1999, ‘A micro-fluxgatemagnetic sensor using micromachined planar solenoidcoils’, Sensors and Actuators, vol. 77, pp. 66–72.Ripka, P, 2003, ‘Advances in fluxgate sensors’, Sensors andActuators A, vol. 106 pp. 8–14.Ripka, P, 2001, Magnetic sensors and magnetometers,Artech House Inc., Norwood, MA.Ripka, P, Choi, SO, Tipek, A, Kawahito, S & Ishida, M, 2001,‘Summetrical core improves micro-fluxgate sensors’,Sensor and Actuators A, vol. 92 pp. 30–36.Wang, Y, Liu, G, Xiong, Y, Yang, J & Tian, Y, 2006, ‘Fabricationof the three-dimensional solenoid type micro magneticsensor’, Journal of Physics: Conference Series, vol. 34, pp.880–884.Yunas, J, Sulaiman, N, Bahadorimehr, AR & Majlis, YB, 2010,‘Design analysis of single layer coupled coils’, in IEEE ICSEProc., pp. 325–328.36

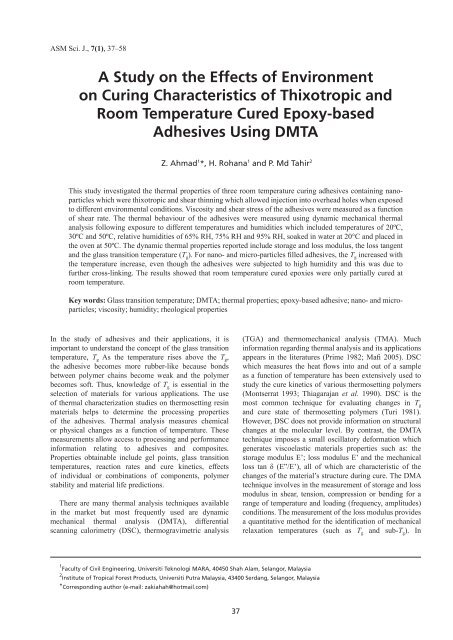

ASM Sci. J., 7(1)A Study on the Effects of Environmenton Curing Characteristics of Thixotropic andRoom Temperature Cured Epoxy-basedAdhesives Using DMTAZ. Ahmad 1 *, H. Rohana 1 and P. Md Tahir 2This study investigated the thermal properties of three room temperature curing adhesives containing nanoparticleswhich were thixotropic and shear thinning which allowed injection into overhead holes when exposedto different environmental conditions. Viscosity and shear stress of the adhesives were measured as a functionof shear rate. The thermal behaviour of the adhesives were measured using dynamic mechanical thermaland the glass transition temperature (T g T g increased withthe temperature increase, even though the adhesives were subjected to high humidity and this was due tofurther cross-linking. The results showed that room temperature cured epoxies were only partially cured atroom temperature.Key words: Glass transition temperature; DMTA; thermal properties; epoxy-based adhesive; nano- and microparticles;viscosity; humidity; rheological propertiesIn the study of adhesives and their applications, it isimportant to understand the concept of the glass transitiontemperature, T g As the temperature rises above the T g ,the adhesive becomes more rubber-like because bondsbetween polymer chains become weak and the polymerbecomes soft. Thus, knowledge of T g is essential in theselection of materials for various applications. The useof thermal characterization studies on thermosetting resinmaterials helps to determine the processing propertiesof the adhesives. Thermal analysis measures chemicalor physical changes as a function of temperature. Thesemeasurements allow access to processing and performanceinformation relating to adhesives and composites.Properties obtainable include gel points, glass transitiontemperatures, reaction rates and cure kinetics, effectsof individual or combinations of components, polymerstability and material life predictions.There are many thermal analysis techniques availablein the market but most frequently used are dynamicmechanical thermal analysis (DMTA), differentialscanning calorimetry (DSC), thermogravimetric analysis(TGA) and thermomechanical analysis (TMA). Muchinformation regarding thermal analysis and its applications as a function of temperature has been extensively used tostudy the cure kinetics of various thermosetting polymers(Montserrat 1993; Thiagarajan et al. most common technique for evaluating changes in T gand cure state of thermosetting polymers (Turi 1981).However, DSC does not provide information on structuralchanges at the molecular level. By contrast, the DMTAtechnique imposes a small oscillatory deformation whichgenerates viscoelastic materials properties such as: thestorage modulus E’; loss modulus E’ and the mechanical changes of the material’s structure during cure. The DMAtechnique involves in the measurement of storage and lossmodulus in shear, tension, compression or bending for arange of temperature and loading (frequency, amplitudes)conditions. The measurement of the loss modulus providesrelaxation temperatures (such as T g and sub-T g ). In1 Faculty of Civil Engineering, Universiti Teknologi MARA, 40450 Shah Alam, Selangor, <strong>Malaysia</strong>2 Institute of Tropical Forest Products, Universiti Putra <strong>Malaysia</strong>, 43400 Serdang, Selangor, <strong>Malaysia</strong>* Corresponding author (e-mail: zakiahah@hotmail.com)37

- Page 1 and 2: ContentsASM Sc. J.Volume 7(1), 2013

- Page 3 and 4: INTERNATIONAL ADVISORY BOARDAhmed Z

- Page 5: The Academy of SciencesMalaysia (AS

- Page 8 and 9: NEWS FOCUSBio-Jet Fuel — Challeng

- Page 10 and 11: ASM Science Journal, Volume 7(1), 2

- Page 12 and 13: NitrogengasAcetylene gasFume hoodGa

- Page 14 and 15: ASM Science Journal, Volume 7(1), 2

- Page 16 and 17: ASM Science Journal, Volume 7(1), 2

- Page 18 and 19: ControllerN 2N 2ValveValvePreheater

- Page 20 and 21: ASM Science Journal, Volume 7(1), 2

- Page 22 and 23: ASM Science Journal, Volume 7(1), 2

- Page 24 and 25: ASM Science Journal, Volume 7(1), 2

- Page 26 and 27: ASM Sci. J., 7(1), 18-22Electron-ph

- Page 28 and 29: v I= v MthASM Science Journal, Volu

- Page 30 and 31: ASM Science Journal, Volume 7(1), 2

- Page 32 and 33: ASM Science Journal, Volume 7(1), 2

- Page 34 and 35: ASM Science Journal, Volume 7(1), 2

- Page 36 and 37: ASM Science Journal, Volume 7(1), 2

- Page 38 and 39: ASM Science Journal, Volume 7(1), 2

- Page 40 and 41: 4.2 × 10 -5Magnetic energy (Em) Ma

- Page 42 and 43: 2.0 × 10 -5Inductance (L)Magnetic

- Page 46 and 47: addition, examination of the freque

- Page 48 and 49: equipped with a computer image anal

- Page 50 and 51: Storage modulus (Pa)1.80E+101.60E+1

- Page 52 and 53: (a)(b)(c)Figure 6. Micrographs: (a)

- Page 54 and 55: 0 20 40 60 80 100 120 140 160 180 2

- Page 56 and 57: 0.00 20 40 60 80 100 120 140 160180

- Page 58 and 59: 0 20 40 60 80 100 120 140 160Temper

- Page 60 and 61: 2.0100.00 20 40 60 80 100 120 140 1

- Page 62 and 63: 3.02.53.02.02.5CB10TSSAlbipoxTimber

- Page 64 and 65: Figure 18. SEM micrographs of the f

- Page 66 and 67: Crawford, E & Lesser, AJ 1998, ‘T

- Page 68 and 69: ASM Science Journal, Volume 7(1), 2

- Page 70 and 71: ASM Science Journal, Volume 7(1), 2

- Page 72 and 73: ASM Science Journal, Volume 7(1), 2

- Page 74 and 75: ASM Science Journal, Volume 7(1), 2

- Page 76 and 77: ASM Science Journal, Volume 7(1), 2

- Page 78 and 79: ASM Science Journal, Volume 7(1), 2

- Page 80 and 81: ASM Science Journal, Volume 7(1), 2

- Page 82 and 83: Climate Change — Environment andI

- Page 84 and 85: ASM Science Journal, Volume 7(1), 2

- Page 86 and 87: ASM Science Journal, Volume 7(1), 2

- Page 88 and 89: ASM Science Journal, Volume 7(1), 2

- Page 90 and 91: Announcements!!!!!!!!!!!!!!!!!!!!!!

- Page 93 and 94: ASM PublicationsMosquitoes and Mosq

- Page 95 and 96:

ASM PublicationsEnhancing Animal Pr

- Page 97 and 98:

ASM PublicationsThe Red Jungle Fowl

- Page 99 and 100:

Vol. 3, No. 1, June : 1823-6782ASM

- Page 101 and 102:

ASM PublicationsIn Pursuit of Excel

- Page 103 and 104:

ASM PublicationsASM Lecture SeriesW

- Page 105 and 106:

ASM PublicationsA Nobel Trip to Lin

- Page 107 and 108:

Vol. 6, No. 2, December 2012 • IS

- Page 109 and 110:

About the JournalMission StatementT

- Page 111:

ASM SCIENCE JOURNAL(ASM Sc. J.)ORDE

- Page 114:

NEWS FOCUSBio-Jet Fuel — Challeng