Contents - Akademi Sains Malaysia

Contents - Akademi Sains Malaysia

Contents - Akademi Sains Malaysia

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

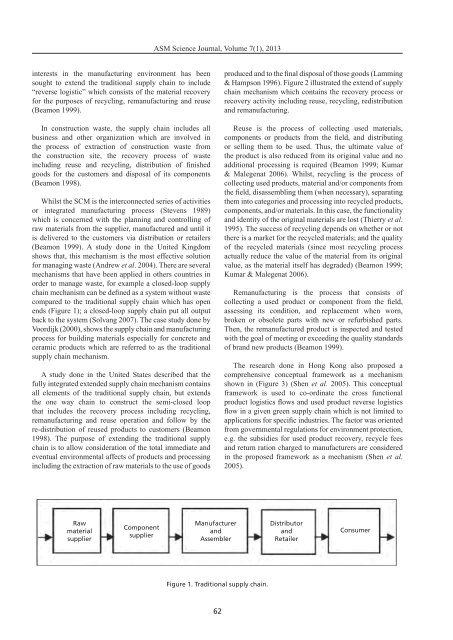

ASM Science Journal, Volume 7(1), 2013interests in the manufacturing environment has beensought to extend the traditional supply chain to include“reverse logistic” which consists of the material recoveryfor the purposes of recycling, remanufacturing and reuse(Beamon 1999).In construction waste, the supply chain includes allbusiness and other organization which are involved inthe process of extraction of construction waste fromthe construction site, the recovery process of wasteincluding reuse and recycling, distribution of finishedgoods for the customers and disposal of its components(Beamon 1998).Whilst the SCM is the interconnected series of activitiesor integrated manufacturing process (Stevens 1989)which is concerned with the planning and controlling ofraw materials from the supplier, manufactured and until itis delivered to the customers via distribution or retailers(Beamon 1999). A study done in the United Kingdomshows that, this mechanism is the most effective solutionfor managing waste (Andrew et al. 2004). There are severalmechanisms that have been applied in others countries inorder to manage waste, for example a closed-loop supplychain mechanism can be defined as a system without wastecompared to the traditional supply chain which has openends (Figure 1); a closed-loop supply chain put all outputback to the system (Solvang 2007). The case study done byVoordijk (2000), shows the supply chain and manufacturingprocess for building materials especially for concrete andceramic products which are referred to as the traditionalsupply chain mechanism.A study done in the United States described that thefully integrated extended supply chain mechanism containsall elements of the traditional supply chain, but extendsthe one way chain to construct the semi-closed loopthat includes the recovery process including recycling,remanufacturing and reuse operation and follow by there-distribution of reused products to customers (Beamon1998). The purpose of extending the traditional supplychain is to allow consideration of the total immediate andeventual environmental affects of products and processingincluding the extraction of raw materials to the use of goodsproduced and to the final disposal of those goods (Lamming& Hampson 1996). Figure 2 illustrated the extend of supplychain mechanism which contains the recovery process orrecovery activity including reuse, recycling, redistributionand remanufacturing.Reuse is the process of collecting used materials,components or products from the field, and distributingor selling them to be used. Thus, the ultimate value ofthe product is also reduced from its original value and noadditional processing is required (Beamon 1999; Kumar& Malegenat 2006). Whilst, recycling is the process ofcollecting used products, material and/or components fromthe field, disassembling them (when necessary), separatingthem into categories and processing into recycled products,components, and/or materials. In this case, the functionalityand identity of the original materials are lost (Thierry et al.1995). The success of recycling depends on whether or notthere is a market for the recycled materials; and the qualityof the recycled materials (since most recycling processactually reduce the value of the material from its originalvalue, as the material itself has degraded) (Beamon 1999;Kumar & Malegenat 2006).Remanufacturing is the process that consists ofcollecting a used product or component from the field,assessing its condition, and replacement when worn,broken or obsolete parts with new or refurbished parts.Then, the remanufactured product is inspected and testedwith the goal of meeting or exceeding the quality standardsof brand new products (Beamon 1999).The research done in Hong Kong also proposed acomprehensive conceptual framework as a mechanismshown in (Figure 3) (Shen et al. 2005). This conceptualframework is used to co-ordinate the cross functionalproduct logistics flows and used product reverse logisticsflow in a given green supply chain which is not limited toapplications for specific industries. The factor was orientedfrom governmental regulations for environment protection,e.g. the subsidies for used product recovery, recycle feesand return ration charged to manufacturers are consideredin the proposed framework as a mechanism (Shen et al.2005).RawmaterialsupplierComponentsupplierManufacturerandAssemblerDistributorandRetailerConsumerFigure 1. Traditional supply chain.62