Contents - Akademi Sains Malaysia

Contents - Akademi Sains Malaysia

Contents - Akademi Sains Malaysia

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

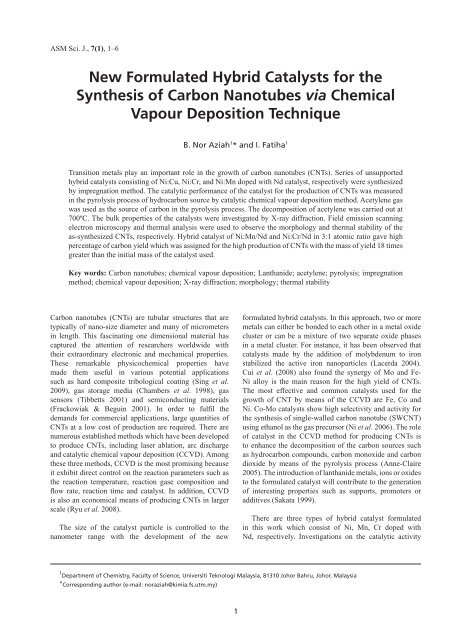

ASM Sci. J., 7(1), 1–6New Formulated Hybrid Catalysts for theSynthesis of Carbon Nanotubes via ChemicalVapour Deposition TechniqueB. Nor Aziah 1 * and I. Fatiha 1Transition metals play an important role in the growth of carbon nanotubes (CNTs). Series of unsupportedhybrid catalysts consisting of Ni:Cu, Ni:Cr, and Ni:Mn doped with Nd catalyst, respectively were synthesizedby impregnation method. The catalytic performance of the catalyst for the production of CNTs was measuredin the pyrolysis process of hydrocarbon source by catalytic chemical vapour deposition method. Acetylene gaswas used as the source of carbon in the pyrolysis process. The decomposition of acetylene was carried out at700ºC. The bulk properties of the catalysts were investigated by X-ray diffraction. Field emission scanningelectron microscopy and thermal analysis were used to observe the morphology and thermal stability of theas-synthesized CNTs, respectively. Hybrid catalyst of Ni:Mn/Nd and Ni:Cr/Nd in 3:1 atomic ratio gave highpercentage of carbon yield which was assigned for the high production of CNTs with the mass of yield 18 timesgreater than the initial mass of the catalyst used.Key words: Carbon nanotubes; chemical vapour deposition; Lanthanide; acetylene; pyrolysis; impregnationmethod; chemical vapour deposition; X-ray diffraction; morphology; thermal stabilityCarbon nanotubes (CNTs) are tubular structures that aretypically of nano-size diameter and many of micrometersin length. This fascinating one dimensional material hascaptured the attention of researchers worldwide withtheir extraordinary electronic and mechanical properties.These remarkable physicochemical properties havemade them useful in various potential applicationssuch as hard composite tribological coating (Sing et al.2009), gas storage media (Chambers et al. 1998), gassensors (Tibbetts 2001) and semiconducting materials(Frackowiak & Beguin 2001). In order to fulfil thedemands for commercial applications, large quantities ofCNTs at a low cost of production are required. There arenumerous established methods which have been developedto produce CNTs, including laser ablation, arc dischargeand catalytic chemical vapour deposition (CCVD). Amongthese three methods, CCVD is the most promising becauseit exhibit direct control on the reaction parameters such asthe reaction temperature, reaction gase composition andflow rate, reaction time and catalyst. In addition, CCVDis also an economical means of producing CNTs in largerscale (Ryu et al. 2008).The size of the catalyst particle is controlled to thenanometer range with the development of the newformulated hybrid catalysts. In this approach, two or moremetals can either be bonded to each other in a metal oxidecluster or can be a mixture of two separate oxide phasesin a metal cluster. For instance, it has been observed thatcatalysts made by the addition of molybdenum to ironstabilized the active iron nanoparticles (Lacerda 2004).Cui et al. (2008) also found the synergy of Mo and Fe-Ni alloy is the main reason for the high yield of CNTs.The most effective and common catalysts used for thegrowth of CNT by means of the CCVD are Fe, Co andNi. Co-Mo catalysts show high selectivity and activity forthe synthesis of single-walled carbon nanotube (SWCNT)using ethanol as the gas precursor (Ni et al. 2006). The roleof catalyst in the CCVD method for producing CNTs isto enhance the decomposition of the carbon sources suchas hydrocarbon compounds, carbon monoxide and carbondioxide by means of the pyrolysis process (Anne-Claire2005). The introduction of lanthanide metals, ions or oxidesto the formulated catalyst will contribute to the generationof interesting properties such as supports, promoters oradditives (Sakata 1999).There are three types of hybrid catalyst formulatedin this work which consist of Ni, Mn, Cr doped withNd, respectively. Investigations on the catalytic activity1 Department of Chemistry, Faculty of Science, Universiti Teknologi <strong>Malaysia</strong>, 81310 Johor Bahru, Johor, <strong>Malaysia</strong>* Corresponding author (e-mail: noraziah@kimia.fs.utm.my)1