EMI Catalog - Spectrum Control

EMI Catalog - Spectrum Control

EMI Catalog - Spectrum Control

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

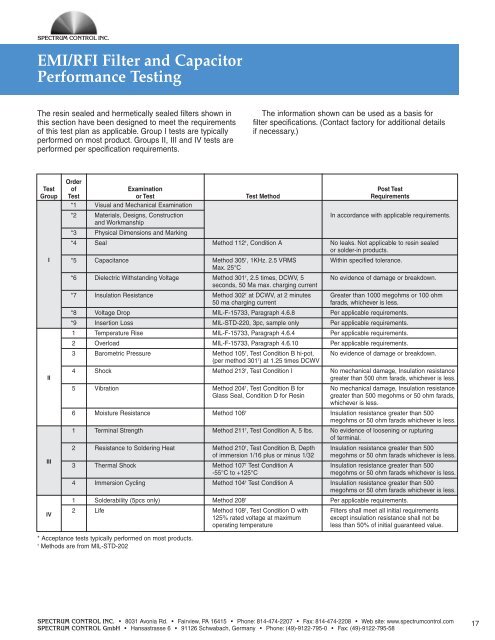

<strong>EMI</strong>/RFI Filter and CapacitorPerformance TestingThe resin sealed and hermetically sealed filters shown inthis section have been designed to meet the requirementsof this test plan as applicable. Group I tests are typicallyperformed on most product. Groups II, III and IV tests areperformed per specification requirements.The information shown can be used as a basis forfilter specifications. (Contact factory for additional detailsif necessary.)TestGroupIIIIIIIVOrderofTest*1*2*3*4*5*6*7*8*9123456123412Examinationor TestVisual and Mechanical ExaminationMaterials, Designs, Constructionand WorkmanshipPhysical Dimensions and MarkingSealCapacitanceDielectric Withstanding VoltageInsulation ResistanceVoltage DropInsertion LossTemperature RiseOverloadBarometric PressureShockVibrationMoisture ResistanceTerminal StrengthResistance to Soldering HeatThermal ShockImmersion CyclingSolderability (5pcs only)LifeTest MethodMethod 112 † , Condition AMethod 305 † , 1KHz. 2.5 VRMSMax. 25°CMethod 301 † , 2.5 times, DCWV, 5seconds, 50 Ma max. charging currentMethod 302 † at DCWV, at 2 minutes50 ma charging currentMIL-F-15733, Paragraph 4.6.8MIL-STD-220, 3pc, sample onlyMIL-F-15733, Paragraph 4.6.4MIL-F-15733, Paragraph 4.6.10Method 105 † , Test Condition B hi-pot,(per method 301 † ) at 1.25 times DCWVMethod 213 † , Test Condition IMethod 204 † , Test Condition B forGlass Seal, Condition D for ResinMethod 106 †Method 211 † , Test Condition A, 5 lbs.Method 210 † , Test Condition B, Depthof immersion 1/16 plus or minus 1/32Method 107 † Test Condition A-55°C to +125°CMethod 104 † Test Condition AMethod 208 †Method 108 † , Test Condition D with125% rated voltage at maximumoperating temperaturePost TestRequirementsIn accordance with applicable requirements.No leaks. Not applicable to resin sealedor solder-in products.Within specified tolerance.No evidence of damage or breakdown.Greater than 1000 megohms or 100 ohmfarads, whichever is less.Per applicable requirements.Per applicable requirements.Per applicable requirements.Per applicable requirements.No evidence of damage or breakdown.No mechanical damage, Insulation resistancegreater than 500 ohm farads, whichever is less.No mechanical damage, Insulation resistancegreater than 500 megohms or 50 ohm farads,whichever is less.Insulation resistance greater than 500megohms or 50 ohm farads whichever is less.No evidence of loosening or rupturingof terminal.Insulation resistance greater than 500megohms or 50 ohm farads whichever is less.Insulation resistance greater than 500megohms or 50 ohm farads whichever is less.Insulation resistance greater than 500megohms or 50 ohm farads whichever is less.Per applicable requirements.Filters shall meet all initial requirementsexcept insulation resistance shall not beless than 50% of initial guaranteed value.* Acceptance tests typically performed on most products.†Methods are from MIL-STD-202SPECTRUM CONTROL INC. • 8031 Avonia Rd. • Fairview, PA 16415 • Phone: 814-474-2207 • Fax: 814-474-2208 • Web site: www.spectrumcontrol.comSPECTRUM CONTROL GmbH • Hansastrasse 6 • 91126 Schwabach, Germany • Phone: (49)-9122-795-0 • Fax: (49)-9122-795-5817