- Page 1 and 2: EMI Filters andFiltered Interconnec

- Page 3 and 4: AControl ProductsSystems Company&Su

- Page 5 and 6: EMI Filters and Filtered Interconne

- Page 7 and 8: EMI Filters and Filtered Interconne

- Page 9 and 10: Spectrum Control’s ExpertiseAs a

- Page 11 and 12: MultilayerDiscoidal CapacitorApplic

- Page 13 and 14: Application GuidelinesInsertion Los

- Page 15 and 16: EMC Testing ServicesSpectrum Contro

- Page 17 and 18: EMI/RFI Filter and CapacitorPerform

- Page 19 and 20: Surface Mount Filtersand InductorsC

- Page 21 and 22: Surface Mount Filters and Inductors

- Page 23 and 24: Surface Mount EMI FiltersFerrite Ch

- Page 25 and 26: Surface Mount EMI FiltersFerrite Ch

- Page 27 and 28: Surface Mount EMI FiltersFerrite Ch

- Page 29 and 30: Surface Mount EMI FiltersFerrite Ch

- Page 31 and 32: Surface Mount High Current EMI Filt

- Page 33 and 34: Surface Mount High Current EMI Filt

- Page 35 and 36: Surface Mount High Current EMI Filt

- Page 37 and 38: Surface MountFerrite InductorsPhysi

- Page 39 and 40: Surface MountFerrite InductorsTypic

- Page 41 and 42: Surface Mount High FrequencyCeramic

- Page 43 and 44: Surface Mount High FrequencyCeramic

- Page 45 and 46: Land Patterns and SolderingTemperat

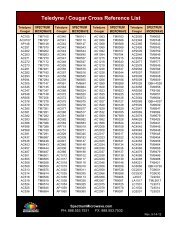

- Page 47 and 48: Competitive Part NumberCross Refere

- Page 49 and 50: Surface Mount EMI FiltersThree Term

- Page 51: LE LM LESurface Mount EMI FiltersTh

- Page 55 and 56: LE LM LESurface Mount EMI FiltersLC

- Page 57 and 58: Insertion Loss6050Surface Mount Low

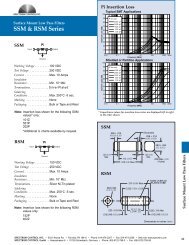

- Page 59 and 60: Surface Mount Low Pass FiltersSSM &

- Page 61 and 62: Surface Mount Low Pass FiltersPSM S

- Page 63 and 64: Low PassEMI FiltersCERTIFIEDSPECTRU

- Page 65 and 66: MLFT FiltersMotor Line Feed-Thru Te

- Page 67 and 68: Solder-in FiltersSolder-in C Circui

- Page 69 and 70: Solder-in FiltersSolder-in Pi Circu

- Page 71 and 72: Spec Mini-Press9900 SeriesThis new

- Page 73 and 74: Resin Sealed Bolt-in FiltersThese f

- Page 75 and 76: Resin Sealed Bolt-in Filters4-40 L

- Page 77 and 78: Resin Sealed Bolt-in Filters8-32 C

- Page 79 and 80: Resin Sealed Bolt-in Filters10-32 C

- Page 81 and 82: Resin Sealed Bolt-in Filters12-28 &

- Page 83 and 84: Resin Sealed Bolt-in Filters5/16-24

- Page 85 and 86: High Current/High VoltageResin Seal

- Page 87 and 88: Hermetically SealedThreaded Case Fi

- Page 89 and 90: Hermetically SealedThreaded Case Fi

- Page 91 and 92: Hermetically SealedThreaded Case Fi

- Page 93 and 94: Hermetically SealedThreaded Case Fi

- Page 95 and 96: Hermetically SealedThreaded Case Fi

- Page 97 and 98: Hermetically SealedThreaded Case Fi

- Page 99 and 100: Hermetically SealedThreaded Case Fi

- Page 101 and 102: Hermetically SealedThreaded Case Fi

- Page 103 and 104:

FilteredArraysCERTIFIEDSPECTRUM CON

- Page 105 and 106:

Filter PlatesEliminating EMI/RFI in

- Page 107 and 108:

Easy Mate ® Filter PlatesPatentedS

- Page 109 and 110:

Easy Mate ® Filter PlatesHi-Densit

- Page 111 and 112:

Easy Mate ® Jr. Filter PlatesDimen

- Page 113 and 114:

Bolt-in Style Filter PlatesCoining

- Page 115 and 116:

Bolt-in Style Filter PlatesHi-Densi

- Page 117 and 118:

Shrouded Latch Filter Plates* Latch

- Page 119 and 120:

Custom CapabilitiesIn addition to o

- Page 121 and 122:

Custom Filter PlatesFilter Plate De

- Page 123 and 124:

Barrier StripFiltered Terminal Bloc

- Page 125 and 126:

PCB MountFiltered Terminal BlocksFi

- Page 127 and 128:

Custom FilteredTerminal BlocksTermi

- Page 129 and 130:

Filtered ConnectorProduct Positioni

- Page 131 and 132:

Advantages of SpectrumFiltered Conn

- Page 133 and 134:

Series F Ferrite FilteredConnectors

- Page 135 and 136:

Series F Ferrite FilteredConnectors

- Page 137 and 138:

Series 100 Chip-CapFiltered Connect

- Page 139 and 140:

Series 100 Chip-CapFiltered Connect

- Page 141 and 142:

Series 500 Low ProfileFiltered Conn

- Page 143 and 144:

Series 500 Low ProfileFiltered Conn

- Page 145 and 146:

Series 600 Hi-DensityFiltered Conne

- Page 147 and 148:

Hi-Density Filtered Adapterfor Tele

- Page 150 and 151:

Series 700Specifications and Connec

- Page 152 and 153:

9Shell SizeSeries 700Pin ContactSol

- Page 154 and 155:

9Shell SizeSeries 700Socket Contact

- Page 156 and 157:

15Series 700Shell SizePin ContactSo

- Page 158 and 159:

Series 700Socket Contact & 15 Pin/S

- Page 160 and 161:

25Series 700Shell SizePin ContactSo

- Page 162 and 163:

Series 700Socket Contact & 25 Pin/S

- Page 164 and 165:

37Series 700Shell SizePin ContactSo

- Page 166 and 167:

Series 700Socket Contact & 37 Pin/S

- Page 168 and 169:

50Series 700Shell SizePin ContactSo

- Page 170 and 171:

Series 700Socket Contact & 50 Pin/S

- Page 172 and 173:

Threaded InsertsD-SubminiatureConne

- Page 174 and 175:

Filtered Combo D-Subminiature Conne

- Page 176 and 177:

Filtered Combo D-Subminiature Conne

- Page 178 and 179:

Filtered Combo D-Subminiature Conne

- Page 180 and 181:

Filtered Combo D-Subminiature Conne

- Page 182 and 183:

Series E (ESD/EFT)Transient Protect

- Page 184 and 185:

Series E (ESD/EFT)Transient Protect

- Page 186 and 187:

Filtered Miniature Ribbon Connector

- Page 188 and 189:

Filtered Miniature Ribbon Connector

- Page 190 and 191:

Filtered ModularJack ConnectorsOrde

- Page 192 and 193:

Filtered Mini-DINConnectorsFiltered

- Page 194 and 195:

The industry wide adoption of conne

- Page 196 and 197:

ESD ProtectedUSB ConnectorsSeries U

- Page 198 and 199:

Waved Metal GasketsProper mounting

- Page 200 and 201:

Custom EngineeredSolutionsFiltered

- Page 202 and 203:

Board & Panel CutoutsEBIFEBIGDPrint

- Page 204 and 205:

Custom Filtered ConnectorsMIL and H

- Page 206 and 207:

MIL-C-38999, Compact ShellOrdering

- Page 208 and 209:

MIL-C-38999, Compact ShellSeries IM

- Page 210 and 211:

MIL-C-38999, Compact ShellSeries II

- Page 212 and 213:

Extended ShellFiltered ConnectorsFi

- Page 214 and 215:

MIL-C-38999, Extended ShellSeries I

- Page 216 and 217:

MIL-C-38999, Extended ShellSeries I

- Page 218 and 219:

MIL-C-38999, Extended ShellSeries I

- Page 220 and 221:

MIL-C-38999, Extended ShellSeries I

- Page 222 and 223:

MIL-C-83723, Extended ShellSeries I

- Page 224 and 225:

MIL-C-83723, Extended ShellSeries I

- Page 226 and 227:

MIL-C-26482, Extended ShellAll exte

- Page 228 and 229:

MIL-C-26482, Extended ShellMS3470 W

- Page 230 and 231:

Custom Filtered ConnectorsWire Harn

- Page 232 and 233:

Quality Acceptance Test Specificati

- Page 234 and 235:

Signal & Power Integrity GroupQuiet

- Page 236 and 237:

Shielding Theory and IntroductionGa

- Page 238 and 239:

Quietshield Fabric-over-FoamProfil

- Page 240 and 241:

Shielding Tapes & FabricFlexible an

- Page 242 and 243:

Conductive ElastomersPHOTO TO COMES

- Page 244 and 245:

Military Cross ReferenceQualified C

- Page 246 and 247:

Military Cross ReferenceQualified C

- Page 248 and 249:

Spectrum Control/AMPPart Number Cro

- Page 250 and 251:

Spectrum Control/AMPPart Number Cro

- Page 252 and 253:

Part Number IndexSpectrum part #Pag

- Page 254 and 255:

Part Number IndexSpectrum part #Pag

- Page 256 and 257:

Part Number IndexSpectrum part #Pag

- Page 258:

Represented or Distributed by:EMI F