- Page 2 and 3:

THE PERFORMANCE DIFFERENCEPRODUCT H

- Page 4 and 5:

Made in U.S.A.From Forge to FinishY

- Page 6 and 7:

The Armstrong Bros. Tool Co. was fo

- Page 9 and 10:

1Armstrong Industrial Hand Tools Ma

- Page 11 and 12:

Industrial Hand Tool Sets1Set 15-00

- Page 13 and 14:

Industrial Hand Tool Sets1Set 15-00

- Page 15 and 16:

Industrial Hand Tool Sets1Set 15-01

- Page 17 and 18:

Industrial Hand Tool Sets1Set 15-02

- Page 19 and 20:

Industrial Hand Tool Sets1Set 15-03

- Page 21 and 22:

Industrial Hand Tool Sets1Set 15-04

- Page 23 and 24:

Industrial Hand Tool Sets1Set 15-05

- Page 25 and 26:

Industrial Hand Tool Sets1Set 15-06

- Page 27 and 28:

Industrial Hand Tool Sets1Set 15-07

- Page 29 and 30:

Industrial Hand Tool Sets1Set 15-08

- Page 31 and 32:

Industrial Hand Tool Sets1Set 15-09

- Page 33 and 34:

Industrial Hand Tool Sets1Set 44-00

- Page 35 and 36:

Industrial Hand Tool Sets1Set 44-01

- Page 37 and 38:

Industrial Hand Tool Sets1Set 44-02

- Page 39 and 40:

Industrial Hand Tool Sets1Set 44-03

- Page 41 and 42:

Industrial Hand Tool Sets1Set 44-04

- Page 43 and 44:

1NOTES:Master Sets1-34

- Page 45 and 46:

2STANDARD SERIESSAFETYFully-recesse

- Page 47 and 48:

Industrial Series219 Drawer Triple

- Page 49 and 50:

Industrial Series212 Drawer Top Che

- Page 51 and 52:

Standard Series2Roller Cabinet / To

- Page 53 and 54:

Standard Series212 Drawer Single Ba

- Page 55 and 56:

Standard Series210 Drawer Top Chest

- Page 57 and 58:

Standard Series26 Drawer Side Cabin

- Page 59 and 60:

Cases and Bars2Steel Cases and Tote

- Page 61:

2NOTES:Tool Storage2-16

- Page 64 and 65:

31/4" DriveSet 15-20053 Pc. 6 Point

- Page 66 and 67:

31/4" DriveSocket SetsSet 15-21025

- Page 68 and 69:

31/4" DriveSocket SetsSet 15-21625

- Page 70 and 71:

31/4" DriveSet 15-24010 Pc. 12 Poin

- Page 72 and 73:

31/4" DriveSocket SetsSet 44-20043

- Page 74 and 75:

31/4" DriveSet 44-21512 Pc. 6 Point

- Page 76 and 77:

3Socket Sets3/8" DriveSet 15-31057

- Page 78 and 79:

33/8" DriveSocket SetsSet 15-33022

- Page 80 and 81:

33/8" DriveSet 15-34512 Pc. 12 Poin

- Page 82 and 83:

33/8" DriveSet 15-37513 Pc. 12 Poin

- Page 84 and 85:

33/8" DriveSet 15-4257 Pc. 3/8" Dri

- Page 86 and 87:

33/8" DriveSet 19-15013 Pc. 12 Poin

- Page 88 and 89:

33/8" DriveSet 44-31029 Pc. 12 Poin

- Page 90 and 91:

33/8" DriveSet 44-32020 Pc. 12 Poin

- Page 92 and 93:

33/8" DriveSet 44-34512 Pc. 6 Point

- Page 94 and 95:

33/8" DriveSet 44-375METRIC6 Pc. 3/

- Page 96 and 97:

31/2" DriveSocket SetsSet 15-51030

- Page 98 and 99:

31/2" DriveSocket SetsSet 15-52026

- Page 100 and 101:

31/2" DriveSet 15-54012 Pc. 12 Poin

- Page 102 and 103:

31/2" DriveSet 15-57019 Pc. 6 Point

- Page 104 and 105:

31/2" DriveSet 15-6056 Pc. 1/2” D

- Page 106 and 107:

31/2" DriveSocket SetsSet 44-500MET

- Page 108 and 109:

31/2" DriveSet 44-52022 Pc. 12 Poin

- Page 110 and 111:

31/2" DriveSet 44-54515 Pc. 6 Point

- Page 112 and 113:

33/4" DriveSocket SetsSet 15-70042

- Page 114 and 115:

33/4" DriveSet 15-71513 Pc. 12 Poin

- Page 116 and 117:

33/4" DriveSet 44-71019 Pc. 12 Poin

- Page 118 and 119:

31" DriveSet 15-81017 Pc. 12 Point

- Page 120 and 121:

STRENGTH & SAFETYRadius corner desi

- Page 122 and 123:

41/4" Drive1/4” Drive 12 Point St

- Page 124 and 125:

41/4" Drive1/4” Drive 4 or 8 Poin

- Page 126 and 127:

41/4" DriveHand Sockets and Drive T

- Page 128 and 129:

41/4" Drive1/4” Drive Round Head

- Page 130 and 131:

43/8" DriveHand Sockets and Drive T

- Page 132 and 133:

43/8" Drive3/8” Drive 8 Point Sta

- Page 134 and 135:

43/8" Drive3/8” Drive Extra Long

- Page 136 and 137:

43/8" DriveHand Sockets and Drive T

- Page 138 and 139:

43/8" DriveHand Sockets and Drive T

- Page 140 and 141:

43/8" Drive3/8” Drive Teardrop Ra

- Page 142 and 143:

43/8" Drive3/8” Drive ExtensionsP

- Page 144 and 145:

41/2" DriveHand Sockets and Drive T

- Page 146 and 147:

41/2" Drive1/2” Drive 8 Point Sta

- Page 148 and 149:

41/2" Drive1/2” Drive Extra Long

- Page 150 and 151:

41/2" DriveHand Sockets and Drive T

- Page 152 and 153:

41/2" DriveHand Sockets and Drive T

- Page 154 and 155:

41/2" Drive1/2” Drive Black Oxide

- Page 156 and 157:

ASME Specs. B107.3 and B107.10M41/2

- Page 158 and 159:

43/4" DriveHand Sockets and Drive T

- Page 160 and 161:

43/4" Drive3/4” Drive ExtensionsP

- Page 162 and 163:

41", 1 1/2” Drive1” Drive Slidi

- Page 164 and 165:

PRODUCT RANGEDrive Sizes: 1/4" to 2

- Page 166 and 167:

53/8" DriveImpact and Power Sockets

- Page 168 and 169:

51/2" DriveImpact and Power Sockets

- Page 170 and 171:

51/2" DriveImpact and Power Sockets

- Page 172 and 173:

51/4" DriveImpact and Power Sockets

- Page 174 and 175:

53/8" DriveImpact and Power Sockets

- Page 176 and 177:

53/8" DriveImpact and Power Sockets

- Page 178 and 179:

51/2" DriveImpact and Power Sockets

- Page 180 and 181:

51/2" DriveImpact and Power Sockets

- Page 182 and 183:

53/4" DriveImpact and Power Sockets

- Page 184 and 185:

53/4" DriveImpact and Power Sockets

- Page 186 and 187:

51" DriveImpact and Power Sockets,

- Page 188 and 189:

51" DriveImpact and Power Sockets,

- Page 190 and 191:

51-1/2" DriveImpact and Power Socke

- Page 192 and 193:

51-1/2" Drive1-1/2" Drive Impact Un

- Page 194 and 195:

5No. 5 Spline DriveImpact and Power

- Page 196 and 197:

STRENGTHModified radius corner desi

- Page 198 and 199:

6Ratcheting Wrench, ReversibleSet 2

- Page 200 and 201:

6Ratcheting Wrench, BoxSet 27-6097

- Page 202 and 203:

6Ratcheting Wrench, ReversibleRever

- Page 204 and 205:

6Ratcheting Wrench, BoxBox Ratcheti

- Page 206 and 207:

6Combination WrenchesSet 25-67511 P

- Page 208 and 209:

6Combination WrenchesIndustrial Wre

- Page 210 and 211:

6Combination WrenchesSet 52-671METR

- Page 212 and 213:

6Combination WrenchesIndustrial Wre

- Page 214 and 215:

6Combination WrenchesIndustrial Wre

- Page 216 and 217:

6Combination WrenchesSet 25-68115 P

- Page 218 and 219:

6Combination WrenchesSet 52-677METR

- Page 220 and 221:

6Combination WrenchesSet 30-6317 Pc

- Page 222 and 223:

6Combination WrenchesSet 25-6028 Pc

- Page 224 and 225:

6Combination WrenchesIndustrial Wre

- Page 226 and 227:

6Combination WrenchesIndustrial Wre

- Page 228 and 229:

6Combination WrenchesIndustrial Wre

- Page 230 and 231:

6Combination WrenchesIndustrial Wre

- Page 232 and 233:

6Combination WrenchesIndustrial Wre

- Page 234 and 235:

6Combination WrenchesIndustrial Wre

- Page 236 and 237:

6Combination WrenchesIndustrial Wre

- Page 238 and 239:

6Combination WrenchesIndustrial Wre

- Page 240 and 241:

6Box End WrenchesSet 26-8527 Pc. 12

- Page 242 and 243:

6Box End WrenchesSet 27-5706 Pc. 12

- Page 244 and 245:

6Box End WrenchesSet 27-6053 Pc. Ra

- Page 246 and 247:

6Box End WrenchesIndustrial Wrenche

- Page 248 and 249:

6Box End WrenchesIndustrial Wrenche

- Page 250 and 251:

6Box End WrenchesIndustrial Wrenche

- Page 252 and 253:

6Open End WrenchesSet 26-28210 Pc.

- Page 254 and 255:

6Open End WrenchesSet 26-7309 Pc. F

- Page 256 and 257:

6Open End WrenchesSet 27-8857 Pc. F

- Page 258 and 259:

6Open End WrenchesSet 28-1555 Pc. F

- Page 260 and 261:

6Open End WrenchesIndustrial Wrench

- Page 262 and 263:

6Open End WrenchesIndustrial Wrench

- Page 264 and 265:

6Open End WrenchesIndustrial Wrench

- Page 266 and 267:

6Ratcheting Flare Nut WrenchesSet 2

- Page 268 and 269:

6Adjustable WrenchesSet 28-8503 Pc.

- Page 270 and 271:

6Pump WrenchesIndustrial Wrenches a

- Page 272 and 273:

6Construction, Striking WrenchesInd

- Page 274 and 275:

6Slugging WrenchesIndustrial Wrench

- Page 276 and 277:

6Spanner, Check Nut WrenchesAdjusta

- Page 278 and 279:

6Pipe ToolsIndustrial Wrenches and

- Page 280 and 281:

STRENGTHEnclosed head design seals

- Page 282 and 283:

7Micrometer Torque WrenchesArmstron

- Page 284 and 285:

7Micrometer Torque Wrenches3/4" Dri

- Page 286 and 287:

7Dial Torque Wrenches1/4" Drive Dia

- Page 288 and 289:

7Electronic Torque WrenchesIntroduc

- Page 290 and 291:

7Electronic Torque WrenchesTorque T

- Page 292 and 293:

7Torque MultipliersPlate Reaction T

- Page 294 and 295:

SAFETYLarger than average handlelen

- Page 296 and 297:

8Screwdriver SetsScrewdrivers and N

- Page 298 and 299:

8Screwdriver SetsSet 66-6086 Pc. St

- Page 300 and 301:

8Screwdriver SetsSet 66-6128 Pc. (S

- Page 302 and 303:

8ScrewdriversScrewdrivers and Nut D

- Page 304 and 305:

8ScrewdriversTorx, Round ShankA1 A2

- Page 306 and 307:

8Electricians ScrewdriversCabinet T

- Page 308 and 309: 8Nut DriversHollow Shaft Nut Driver

- Page 310 and 311: 8Offset ScrewdriversOffset, Standar

- Page 312 and 313: SAFETYSpecially designed fastener i

- Page 314 and 315: 9Tongue & Groove PliersTongue & Gro

- Page 316 and 317: 9Diagonal PliersLong Reach High Lev

- Page 318 and 319: 9Chain Nose PliersLong Reach Chain

- Page 320 and 321: 9Needle Nose, Specialty PliersNeedl

- Page 322 and 323: 9Pliers and SnipsWire Stripping Pli

- Page 324 and 325: 9Pliers and SnipsRetaining Ring Pli

- Page 326 and 327: 9Pliers and SnipsRetaining Ring Pli

- Page 328 and 329: 9Pliers and SnipsRetaining Ring Pli

- Page 330 and 331: 9Pliers and SnipsRetaining Ring Pli

- Page 332 and 333: 9Pliers and SnipsWiretwister Pliers

- Page 334 and 335: STRENGTHCutting edges are ground to

- Page 336 and 337: 10Punches, Chisels, Pry Bars and Ha

- Page 338 and 339: 10Punch SetsPunches, Chisels, Pry B

- Page 340 and 341: 10Cold ChiselsPunch and Chisel Hold

- Page 342 and 343: 10Pin PunchesPunches, Chisels, Pry

- Page 344 and 345: 10Pry BarsSet 70-5794 Pc. Pry Bar S

- Page 346 and 347: 10Dead Blow HammersHOT CAST DEAD BL

- Page 348 and 349: 10Soft Face Hammers, HammersPunches

- Page 350 and 351: 10HammersDouble Face Sledge Hammers

- Page 352 and 353: STRENGTHThreads are roll formed for

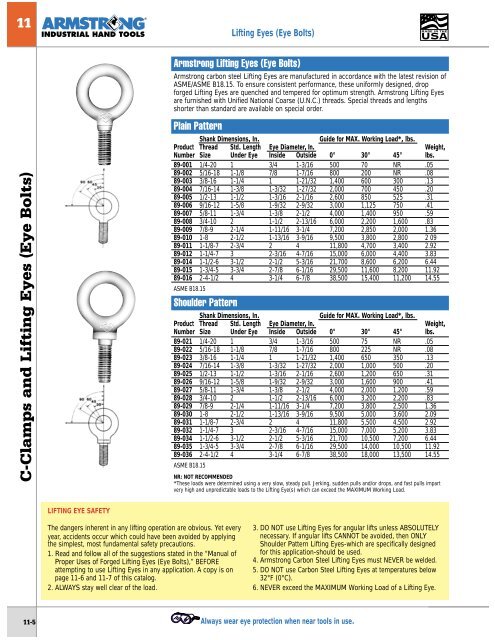

- Page 354 and 355: 11C-ClampsC-Clamps and Lifting Eyes

- Page 356 and 357: 11C-ClampsDeep Throat PatternOur mo

- Page 360 and 361: 11Proper Uses of Forged Lifting Eye

- Page 362 and 363: ACCESSAdjustable frame for usewith

- Page 364 and 365: 12Miscellaneous ToolsAuto-Return, L

- Page 366 and 367: 12Feeler GaugesSet 70-801Combinatio

- Page 368 and 369: 12Hacksaws, KnivesFlat Frame Hacksa

- Page 370 and 371: 12Multi-Purpose Tools, Knives3” L

- Page 372 and 373: STRENGTHForcing screw is recessed t

- Page 374 and 375: 13Puller SetsSet 72-498Multi-purpos

- Page 376 and 377: 13Puller SetsSet 72-496Blind Hole P

- Page 378 and 379: 13Standard Pullers13-Ton Standard J

- Page 380 and 381: 13Push, Cone, Specialty PullersSet

- Page 382 and 383: 13AccessoriesShaft Protector SetDes

- Page 384 and 385: TOOL POSTS WITH TOOL HOLDERSMACHINE

- Page 386 and 387: 14Work-Holding ToolsWork Holding To

- Page 388 and 389: 14Work-Holding ToolsWork Holding To

- Page 390 and 391: 14Cutting ToolsWork Holding Tools,

- Page 392 and 393: 14Cutting ToolsWork Holding Tools,

- Page 394 and 395: 14Cutting ToolsWork Holding Tools,

- Page 396 and 397: 14Cutting ToolsWork Holding Tools,

- Page 398 and 399: 14Shop AccessoriesWork Holding Tool

- Page 400 and 401: ALLEN ®HEX KEYS AND SETSHeat treat

- Page 402 and 403: 15Ball Plus L KeysBall Plus Long A

- Page 404 and 405: 15Ball Plus Screwdriver HandlesBall

- Page 406 and 407: 15L KeysShort Arm Sets — In Plast

- Page 408 and 409:

15Fold-UpsDURACAST ® Fold-UpsProdu

- Page 410 and 411:

15Fold-UpsLong HI-VIS Fold-UpsProd

- Page 412 and 413:

15L KeysLong Arm Sets — In Vinyl

- Page 414 and 415:

15Loop Handle Keys, PLAS-T-KEYS9" L

- Page 416 and 417:

15L KeysHex Key Assortment 56882An

- Page 418 and 419:

K-D SPECIALTY TOOLSSWIVOIL TM OILFI

- Page 420 and 421:

163 Pc. Fan Clutch Wrench Kit Item

- Page 422 and 423:

16Universal Overhead Valve Spring C

- Page 424 and 425:

16Universal 3-Jaw Oil Filter Wrench

- Page 426 and 427:

16Seal Puller Item Number: 3245Use

- Page 428 and 429:

16Ignition & Electrical, Brake & Wh

- Page 430 and 431:

16Brake Bleeder Tank Item Number: 2

- Page 432 and 433:

16Hand Bearing Packer Item Number:

- Page 434 and 435:

16CV Joint Boot Clamp Pliers Item N

- Page 436 and 437:

16Cooling System Check Kit Item Num

- Page 438 and 439:

163 Pc. Heavy Duty Hook and Pick Se

- Page 440 and 441:

16SAE Impact Driver Set Item Number

- Page 442 and 443:

165 Pc. Twist-Out Socket Set Item N

- Page 444 and 445:

1610 Pc. Internal/External Twist Ou

- Page 446 and 447:

164 Pc. Outside Micrometer Set Item

- Page 448 and 449:

166” Digital Caliper with Large L

- Page 450 and 451:

16Rotor/Ball Joint Set with Locking

- Page 452 and 453:

16Mini Stand Item Number: 3764Featu

- Page 454 and 455:

INDUSTRIAL KEYED CHUCKSPLAIN BEARIN

- Page 456 and 457:

17Ball Bearing Chucks• Ball beari

- Page 458 and 459:

17Plain Bearing Chucks - Thread Mou

- Page 460 and 461:

17Medium Duty Industrial Keyless Ch

- Page 462 and 463:

17Drain Chuck• Specifically desig

- Page 464 and 465:

AMaster Set ContentsSet 15-001 1192

- Page 466 and 467:

AMaster Set ContentsSet 15-001 1192

- Page 468 and 469:

AMaster Set ContentsSet 15-006 761

- Page 470 and 471:

AMaster Set ContentsSet 15-017 453

- Page 472 and 473:

AMaster Set ContentsSet 15-032 406

- Page 474 and 475:

AMaster Set ContentsSet 15-047 417

- Page 476 and 477:

AMaster Set ContentsSet 15-071 78 P

- Page 478 and 479:

AMaster Set ContentsSet 44-007 248

- Page 480 and 481:

AMaster Set ContentsSet 44-022 138

- Page 482 and 483:

BReplacement PartsPipe Wrench Parts

- Page 484 and 485:

CWrench Sizing ChartsStandard Wrenc

- Page 486 and 487:

CMetric Conversion ChartsMetric Con

- Page 488 and 489:

CTorque Conversion ChartsIn the Int

- Page 490 and 491:

DMerchandising Display ProgramMerch

- Page 492 and 493:

DMerchandising Display Program95-93

- Page 494 and 495:

DMerchandising Display ProgramMerch

- Page 496 and 497:

DMerchandising Display Program95-94

- Page 498 and 499:

EAlphabetical IndexAlphabetical Ind

- Page 500 and 501:

EAlphabetical IndexAlphabetical Ind

- Page 502 and 503:

F-1Product Number IndexFProduct Num

- Page 504 and 505:

F-3Product Number IndexFProduct Num

- Page 506 and 507:

F-5Product Number IndexFProduct Num

- Page 508 and 509:

F-7Product Number IndexFProduct Num

- Page 510 and 511:

F-9Product Number IndexFProduct Num

- Page 512 and 513:

F-11Product Number IndexFProduct Nu

- Page 514 and 515:

F-13Product Number IndexFProduct Nu

- Page 516 and 517:

FProduct Number IndexProduct Number

- Page 518 and 519:

FProduct Number Index3472 .........

- Page 520:

Danaher Tool Group11011 McCormick R