Understanding the Software Options

Understanding the Software Options

Understanding the Software Options

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Operator<br />

interface<br />

node<br />

Transmitters<br />

and<br />

final control<br />

elements<br />

Regulatory<br />

control<br />

node<br />

Fieldbus<br />

Operator<br />

interface<br />

node<br />

Transmitters<br />

and<br />

final control<br />

elements<br />

E<strong>the</strong>rnet(s)<br />

Those familiar with standards in<br />

<strong>the</strong> computer industry were not at all<br />

surprised by <strong>the</strong> standard that eventually<br />

appeared for Fieldbus. The ISA<br />

(Instrument Society of America) took<br />

<strong>the</strong> lead to develop a standard, one<br />

complication being that <strong>the</strong> standard<br />

had to be a world-wide standard and<br />

not just a U.S. standard.<br />

But in addition, <strong>the</strong> approach effectively<br />

envisioned <strong>the</strong> standard driving<br />

<strong>the</strong> technology — again, trying to swim<br />

upstream. Everyone was on board until<br />

<strong>the</strong> deliberations started to converge to a<br />

single architecture, but <strong>the</strong>n <strong>the</strong> wheels<br />

started to come off. In order to get a<br />

standard for Fieldbus, five networking<br />

architectures were incorporated into<br />

<strong>the</strong> standard. So much for <strong>the</strong> notion<br />

that a standard should provide one —<br />

and only one — way to do something.<br />

Ever wonder why <strong>the</strong> various control<br />

system suppliers use different units<br />

for PID tuning coefficients? Want a<br />

standard? Following <strong>the</strong> practices in<br />

<strong>the</strong> computer industry, <strong>the</strong> standard<br />

would be as follows:<br />

1. The proportional mode tuning parameter<br />

can be controller gain, proportional<br />

gain, or proportional band.<br />

2. The integral mode tuning parameter<br />

can be reset time, reset rate, or<br />

reset gain.<br />

3. The derivative mode tuning parameter<br />

can be derivative time or derivative<br />

gain.<br />

4. The units for time may be seconds,<br />

minutes, hours, or fortnights.<br />

The benefits? Specification writers<br />

could demand compliance, suppliers<br />

could promise compliance, and <strong>the</strong><br />

ISA could make money selling copies<br />

of <strong>the</strong> standard — clearly a win-winwin<br />

proposition.<br />

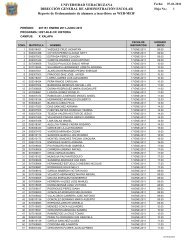

Customary architecture<br />

Figure 1 presents a generic block diagram<br />

for process control systems. The<br />

central component is a communica-<br />

Special<br />

function<br />

node<br />

Transmitters<br />

and<br />

final control<br />

elements<br />

Regulatory<br />

control<br />

node<br />

Fieldbus<br />

Special<br />

function<br />

node<br />

Transmitters<br />

and<br />

final control<br />

elements<br />

FIGURE 1.<br />

Architecture<br />

of a typical<br />

process<br />

control system<br />

tions network that enables information<br />

to be quickly and reliably transferred<br />

between nodes. Each node consists of<br />

a computer whose function falls into<br />

one of <strong>the</strong> following categories:<br />

Regulatory control node. In a continuous<br />

plant, this is provided by PID<br />

function blocks complemented by various<br />

algorithms. In a batch plant, <strong>the</strong><br />

simple and repetitive sequences (pulling<br />

vacuum, transferring a material,<br />

and so on) are implemented in <strong>the</strong><br />

regulatory control node. Except for a<br />

few LEDs that indicate power, run/<br />

halt, fault status, and so on, a regulatory<br />

control node conveys no information<br />

directly to humans. Redundancy<br />

is usually available for <strong>the</strong>se nodes.<br />

Operator interface node. This node<br />

presents information to <strong>the</strong> process operator<br />

and accepts commands from <strong>the</strong><br />

process operator. In <strong>the</strong> ideal world, no<br />

o<strong>the</strong>r functions are implemented in an<br />

operator interface node, but in practice,<br />

o<strong>the</strong>r functions are sometimes<br />

“piggy-backed” onto <strong>the</strong> operator interface<br />

node. Usually <strong>the</strong> easiest way<br />

to address failure issues is to provide<br />

multiple operator interface nodes.<br />

Special functions node. A common<br />

special function is data collection<br />

(historian). An individual node can be<br />

dedicated to a special function, or one<br />

or more special functions can be implemented<br />

in a general purpose computer.<br />

Failure is usually not an issue, as most<br />

processes can be operated (perhaps not<br />

very well) without <strong>the</strong>se nodes.<br />

In Figure 1, <strong>the</strong> various nodes are<br />

connected by a communications network.<br />

This raises <strong>the</strong> specter of a<br />

ra<strong>the</strong>r nasty failure situation. A total<br />

failure of <strong>the</strong> communications network<br />

results in <strong>the</strong> dreaded “loss of<br />

view” — each node continues to function,<br />

but <strong>the</strong> operator interface nodes<br />

cannot acquire data from or send data<br />

to <strong>the</strong> regulatory control nodes. There<br />

are numerous consequences, most of<br />

which are bad. This must be addressed<br />

using options such as redundancy for<br />

<strong>the</strong> communications network, multiple<br />

communications networks with <strong>the</strong><br />

operator interface nodes spread over<br />

two or more networks, or o<strong>the</strong>rwise.<br />

As <strong>the</strong> computer industry evolved,<br />

E<strong>the</strong>rnet became <strong>the</strong> default standard<br />

for networking. For control applications,<br />

concerns about collisions and predictability<br />

were raised. But what can<br />

compete with a 1 GHz E<strong>the</strong>rnet whose<br />

components are readily available and<br />

very cost competitive? As always, you<br />

will be amazed at our flexibility when<br />

we see <strong>the</strong> price. Apparently a few collisions<br />

aren’t that bad after all.<br />

The initial installations of both smart<br />

transmitters and smart valves relied<br />

on <strong>the</strong> traditional 4–20-mA current<br />

loop to interface to <strong>the</strong> control system.<br />

Configuration was via a hand-held programmer<br />

that ei<strong>the</strong>r plugged directly<br />

into <strong>the</strong> field device or transmitted via<br />

a signal superimposed on <strong>the</strong> 4–20-mA<br />

current loop. This approach permitted<br />

<strong>the</strong> advantages of both smart transmitters<br />

and smart valves to be realized,<br />

but networking <strong>the</strong> field devices would<br />

make much more possible.<br />

Such a network became known as<br />

Fieldbus and is included in <strong>the</strong> configuration<br />

in Figure 1. In process control,<br />

<strong>the</strong> competition appears to have narrowed<br />

to two:<br />

Foundation Fieldbus. This technology<br />

is more common in <strong>the</strong> U.S.<br />

Profibus. This technology is more<br />

common in Europe.<br />

These are well on <strong>the</strong> way to displacing<br />

<strong>the</strong> traditional current loop<br />

interfaces.<br />

DCS architectures<br />

DCSs date from <strong>the</strong> 1980s, with <strong>the</strong><br />

initial products designed primarily<br />

for petroleum refining. However, <strong>the</strong>y<br />

quickly expanded to o<strong>the</strong>r industries,<br />

including specialty batch.<br />

The early products tended to be focused<br />

in one of <strong>the</strong> following directions:<br />

Continuous control. An extensive<br />

set of algorithms complemented <strong>the</strong><br />

PID control function to provide whatever<br />

was required to automate a continuous<br />

process.<br />

Sequence control. Although <strong>the</strong>se<br />

also provided <strong>the</strong> PID control function,<br />

<strong>the</strong> extensions were mainly features<br />

CHEMICAL ENGINEERING WWW.CHE.COM AUGUST 2011 31