Understanding the Software Options

Understanding the Software Options

Understanding the Software Options

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

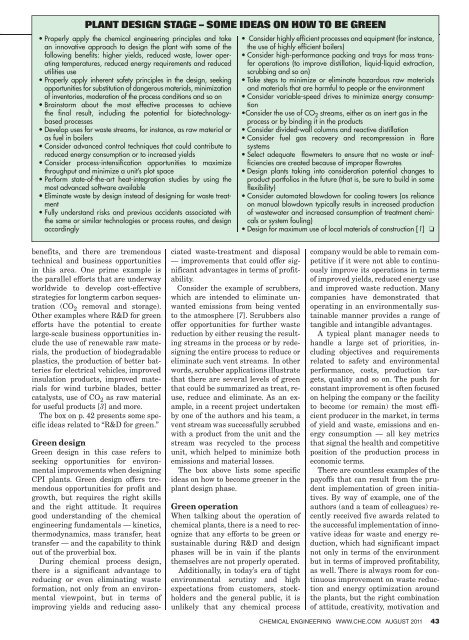

PLANT DESIGN STAGE – SOME IDEAS ON HOW TO BE GREEN<br />

• Properly apply <strong>the</strong> chemical engineering principles and take<br />

an innovative approach to design <strong>the</strong> plant with some of <strong>the</strong><br />

following benefits: higher yields, reduced waste, lower operating<br />

temperatures, reduced energy requirements and reduced<br />

utilities use<br />

• Properly apply inherent safety principles in <strong>the</strong> design, seeking<br />

opportunities for substitution of dangerous materials, minimization<br />

of inventories, moderation of <strong>the</strong> process conditions and so on<br />

• Brainstorm about <strong>the</strong> most effective processes to achieve<br />

<strong>the</strong> final result, including <strong>the</strong> potential for biotechnologybased<br />

processes<br />

• Develop uses for waste streams, for instance, as raw material or<br />

as fuel in boilers<br />

• Consider advanced control techniques that could contribute to<br />

reduced energy consumption or to increased yields<br />

• Consider process-intensification opportunities to maximize<br />

throughput and minimize a unit’s plot space<br />

• Perform state-of-<strong>the</strong>-art heat-integration studies by using <strong>the</strong><br />

most advanced software available<br />

• Eliminate waste by design instead of designing for waste treatment<br />

• Fully understand risks and previous accidents associated with<br />

<strong>the</strong> same or similar technologies or process routes, and design<br />

accordingly<br />

benefits, and <strong>the</strong>re are tremendous<br />

technical and business opportunities<br />

in this area. One prime example is<br />

<strong>the</strong> parallel efforts that are underway<br />

worldwide to develop cost-effective<br />

strategies for longterm carbon sequestration<br />

(CO 2 removal and storage).<br />

O<strong>the</strong>r examples where R&D for green<br />

efforts have <strong>the</strong> potential to create<br />

large-scale business opportunities include<br />

<strong>the</strong> use of renewable raw materials,<br />

<strong>the</strong> production of biodegradable<br />

plastics, <strong>the</strong> production of better batteries<br />

for electrical vehicles, improved<br />

insulation products, improved materials<br />

for wind turbine blades, better<br />

catalysts, use of CO 2 as raw material<br />

for useful products [3] and more.<br />

The box on p. 42 presents some specific<br />

ideas related to “R&D for green.”<br />

Green design<br />

Green design in this case refers to<br />

seeking opportunities for environmental<br />

improvements when designing<br />

CPI plants. Green design offers tremendous<br />

opportunities for profit and<br />

growth, but requires <strong>the</strong> right skills<br />

and <strong>the</strong> right attitude. It requires<br />

good understanding of <strong>the</strong> chemical<br />

engineering fundamentals — kinetics,<br />

<strong>the</strong>rmodynamics, mass transfer, heat<br />

transfer — and <strong>the</strong> capability to think<br />

out of <strong>the</strong> proverbial box.<br />

During chemical process design,<br />

<strong>the</strong>re is a significant advantage to<br />

reducing or even eliminating waste<br />

formation, not only from an environmental<br />

viewpoint, but in terms of<br />

improving yields and reducing asso-<br />

ciated waste-treatment and disposal<br />

— improvements that could offer significant<br />

advantages in terms of profitability.<br />

Consider <strong>the</strong> example of scrubbers,<br />

which are intended to eliminate unwanted<br />

emissions from being vented<br />

to <strong>the</strong> atmosphere [7]. Scrubbers also<br />

offer opportunities for fur<strong>the</strong>r waste<br />

reduction by ei<strong>the</strong>r reusing <strong>the</strong> resulting<br />

streams in <strong>the</strong> process or by redesigning<br />

<strong>the</strong> entire process to reduce or<br />

eliminate such vent streams. In o<strong>the</strong>r<br />

words, scrubber applications illustrate<br />

that <strong>the</strong>re are several levels of green<br />

that could be summarized as treat, reuse,<br />

reduce and eliminate. As an example,<br />

in a recent project undertaken<br />

by one of <strong>the</strong> authors and his team, a<br />

vent stream was successfully scrubbed<br />

with a product from <strong>the</strong> unit and <strong>the</strong><br />

stream was recycled to <strong>the</strong> process<br />

unit, which helped to minimize both<br />

emissions and material losses.<br />

The box above lists some specific<br />

ideas on how to become greener in <strong>the</strong><br />

plant design phase.<br />

Green operation<br />

When talking about <strong>the</strong> operation of<br />

chemical plants, <strong>the</strong>re is a need to recognize<br />

that any efforts to be green or<br />

sustainable during R&D and design<br />

phases will be in vain if <strong>the</strong> plants<br />

<strong>the</strong>mselves are not properly operated.<br />

Additionally, in today’s era of tight<br />

environmental scrutiny and high<br />

expectations from customers, stockholders<br />

and <strong>the</strong> general public, it is<br />

unlikely that any chemical process<br />

• Consider highly efficient processes and equipment (for instance,<br />

<strong>the</strong> use of highly efficient boilers)<br />

• Consider high-performance packing and trays for mass transfer<br />

operations (to improve distillation, liquid-liquid extraction,<br />

scrubbing and so on)<br />

• Take steps to minimize or eliminate hazardous raw materials<br />

and materials that are harmful to people or <strong>the</strong> environment<br />

• Consider variable-speed drives to minimize energy consumption<br />

•Consider <strong>the</strong> use of CO 2 streams, ei<strong>the</strong>r as an inert gas in <strong>the</strong><br />

process or by binding it in <strong>the</strong> products<br />

• Consider divided-wall columns and reactive distillation<br />

• Consider fuel gas recovery and recompression in flare<br />

systems<br />

• Select adequate flowmeters to ensure that no waste or inefficiencies<br />

are created because of improper flowrates<br />

• Design plants taking into consideration potential changes to<br />

product portfolios in <strong>the</strong> future (that is, be sure to build in some<br />

flexibility)<br />

• Consider automated blowdown for cooling towers (as reliance<br />

on manual blowdown typically results in increased production<br />

of wastewater and increased consumption of treatment chemicals<br />

or system fouling)<br />

• Design for maximum use of local materials of construction [1] ❏<br />

company would be able to remain competitive<br />

if it were not able to continuously<br />

improve its operations in terms<br />

of improved yields, reduced energy use<br />

and improved waste reduction. Many<br />

companies have demonstrated that<br />

operating in an environmentally sustainable<br />

manner provides a range of<br />

tangible and intangible advantages.<br />

A typical plant manager needs to<br />

handle a large set of priorities, including<br />

objectives and requirements<br />

related to safety and environmental<br />

performance, costs, production targets,<br />

quality and so on. The push for<br />

constant improvement is often focused<br />

on helping <strong>the</strong> company or <strong>the</strong> facility<br />

to become (or remain) <strong>the</strong> most efficient<br />

producer in <strong>the</strong> market, in terms<br />

of yield and waste, emissions and energy<br />

consumption — all key metrics<br />

that signal <strong>the</strong> health and competitive<br />

position of <strong>the</strong> production process in<br />

economic terms.<br />

There are countless examples of <strong>the</strong><br />

payoffs that can result from <strong>the</strong> prudent<br />

implementation of green initiatives.<br />

By way of example, one of <strong>the</strong><br />

authors (and a team of colleagues) recently<br />

received five awards related to<br />

<strong>the</strong> successful implementation of innovative<br />

ideas for waste and energy reduction,<br />

which had significant impact<br />

not only in terms of <strong>the</strong> environment<br />

but in terms of improved profitability,<br />

as well. There is always room for continuous<br />

improvement on waste reduction<br />

and energy optimization around<br />

<strong>the</strong> plants, but <strong>the</strong> right combination<br />

of attitude, creativity, motivation and<br />

CHEMICAL ENGINEERING WWW.CHE.COM AUGUST 2011 43