OL_P1254 Model (1) - TECO-Westinghouse Motor Company

OL_P1254 Model (1) - TECO-Westinghouse Motor Company

OL_P1254 Model (1) - TECO-Westinghouse Motor Company

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

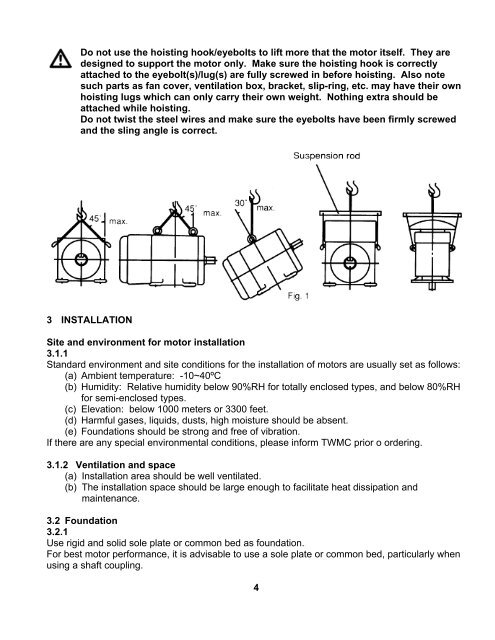

Do not use the hoisting hook/eyebolts to lift more that the motor itself. They aredesigned to support the motor only. Make sure the hoisting hook is correctlyattached to the eyebolt(s)/lug(s) are fully screwed in before hoisting. Also notesuch parts as fan cover, ventilation box, bracket, slip-ring, etc. may have their ownhoisting lugs which can only carry their own weight. Nothing extra should beattached while hoisting.Do not twist the steel wires and make sure the eyebolts have been firmly screwedand the sling angle is correct.3 INSTALLATIONSite and environment for motor installation3.1.1Standard environment and site conditions for the installation of motors are usually set as follows:(a) Ambient temperature: -10~40ºC(b) Humidity: Relative humidity below 90%RH for totally enclosed types, and below 80%RHfor semi-enclosed types.(c) Elevation: below 1000 meters or 3300 feet.(d) Harmful gases, liquids, dusts, high moisture should be absent.(e) Foundations should be strong and free of vibration.If there are any special environmental conditions, please inform TWMC prior o ordering.3.1.2 Ventilation and space(a) Installation area should be well ventilated.(b) The installation space should be large enough to facilitate heat dissipation andmaintenance.3.2 Foundation3.2.1Use rigid and solid sole plate or common bed as foundation.For best motor performance, it is advisable to use a sole plate or common bed, particularly whenusing a shaft coupling.4