OL_P1254 Model (1) - TECO-Westinghouse Motor Company

OL_P1254 Model (1) - TECO-Westinghouse Motor Company

OL_P1254 Model (1) - TECO-Westinghouse Motor Company

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

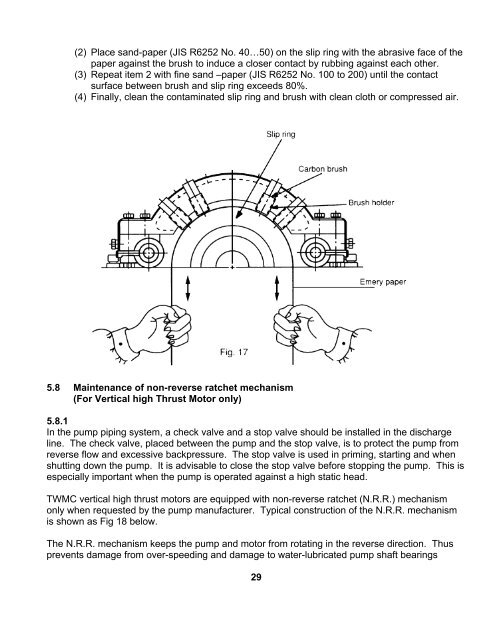

(2) Place sand-paper (JIS R6252 No. 40…50) on the slip ring with the abrasive face of thepaper against the brush to induce a closer contact by rubbing against each other.(3) Repeat item 2 with fine sand –paper (JIS R6252 No. 100 to 200) until the contactsurface between brush and slip ring exceeds 80%.(4) Finally, clean the contaminated slip ring and brush with clean cloth or compressed air.5.8 Maintenance of non-reverse ratchet mechanism(For Vertical high Thrust <strong>Motor</strong> only)5.8.1In the pump piping system, a check valve and a stop valve should be installed in the dischargeline. The check valve, placed between the pump and the stop valve, is to protect the pump fromreverse flow and excessive backpressure. The stop valve is used in priming, starting and whenshutting down the pump. It is advisable to close the stop valve before stopping the pump. This isespecially important when the pump is operated against a high static head.TWMC vertical high thrust motors are equipped with non-reverse ratchet (N.R.R.) mechanismonly when requested by the pump manufacturer. Typical construction of the N.R.R. mechanismis shown as Fig 18 below.The N.R.R. mechanism keeps the pump and motor from rotating in the reverse direction. Thusprevents damage from over-speeding and damage to water-lubricated pump shaft bearings29