OL_P1254 Model (1) - TECO-Westinghouse Motor Company

OL_P1254 Model (1) - TECO-Westinghouse Motor Company

OL_P1254 Model (1) - TECO-Westinghouse Motor Company

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

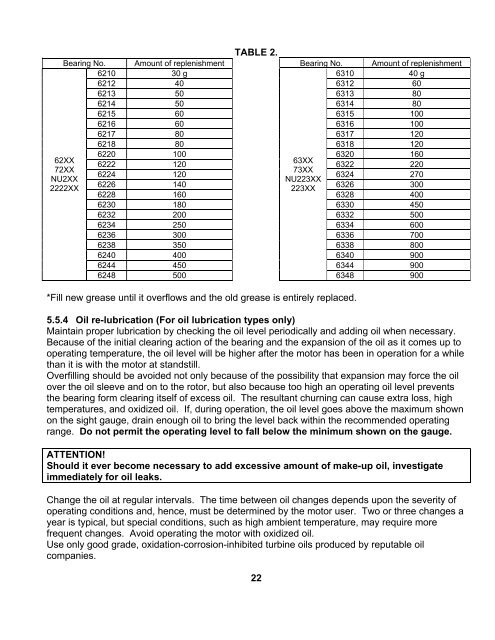

TABLE 2.Bearing No. Amount of replenishment Bearing No. Amount of replenishment6210 30 g 6310 40 g6212 40 6312 606213 50 6313 806214 50 6314 806215 60 6315 1006216 60 6316 1006217 80 6317 1206218 80 6318 1206220 100 6320 16062XX72XXNU2XX2222XX6222 12063XX6322 22073XX6224 120 6324 270NU223XX6226 140223XX6326 3006228 160 6328 4006230 180 6330 4506232 200 6332 5006234 250 6334 6006236 300 6336 7006238 350 6338 8006240 400 6340 9006244 450 6344 9006248 5006348 900*Fill new grease until it overflows and the old grease is entirely replaced.5.5.4 Oil re-lubrication (For oil lubrication types only)Maintain proper lubrication by checking the oil level periodically and adding oil when necessary.Because of the initial clearing action of the bearing and the expansion of the oil as it comes up tooperating temperature, the oil level will be higher after the motor has been in operation for a whilethan it is with the motor at standstill.Overfilling should be avoided not only because of the possibility that expansion may force the oilover the oil sleeve and on to the rotor, but also because too high an operating oil level preventsthe bearing form clearing itself of excess oil. The resultant churning can cause extra loss, hightemperatures, and oxidized oil. If, during operation, the oil level goes above the maximum shownon the sight gauge, drain enough oil to bring the level back within the recommended operatingrange. Do not permit the operating level to fall below the minimum shown on the gauge.ATTENTION!Should it ever become necessary to add excessive amount of make-up oil, investigateimmediately for oil leaks.Change the oil at regular intervals. The time between oil changes depends upon the severity ofoperating conditions and, hence, must be determined by the motor user. Two or three changes ayear is typical, but special conditions, such as high ambient temperature, may require morefrequent changes. Avoid operating the motor with oxidized oil.Use only good grade, oxidation-corrosion-inhibited turbine oils produced by reputable oilcompanies.22