OL_P1254 Model (1) - TECO-Westinghouse Motor Company

OL_P1254 Model (1) - TECO-Westinghouse Motor Company

OL_P1254 Model (1) - TECO-Westinghouse Motor Company

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

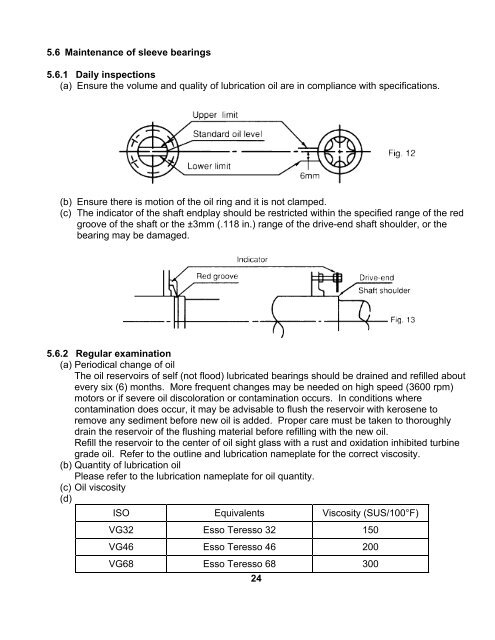

5.6 Maintenance of sleeve bearings5.6.1 Daily inspections(a) Ensure the volume and quality of lubrication oil are in compliance with specifications.(b) Ensure there is motion of the oil ring and it is not clamped.(c) The indicator of the shaft endplay should be restricted within the specified range of the redgroove of the shaft or the ±3mm (.118 in.) range of the drive-end shaft shoulder, or thebearing may be damaged.5.6.2 Regular examination(a) Periodical change of oilThe oil reservoirs of self (not flood) lubricated bearings should be drained and refilled aboutevery six (6) months. More frequent changes may be needed on high speed (3600 rpm)motors or if severe oil discoloration or contamination occurs. In conditions wherecontamination does occur, it may be advisable to flush the reservoir with kerosene toremove any sediment before new oil is added. Proper care must be taken to thoroughlydrain the reservoir of the flushing material before refilling with the new oil.Refill the reservoir to the center of oil sight glass with a rust and oxidation inhibited turbinegrade oil. Refer to the outline and lubrication nameplate for the correct viscosity.(b) Quantity of lubrication oilPlease refer to the lubrication nameplate for oil quantity.(c) Oil viscosity(d)ISO Equivalents Viscosity (SUS/100°F)VG32 Esso Teresso 32 150VG46 Esso Teresso 46 200VG68 Esso Teresso 68 30024