OL_P1254 Model (1) - TECO-Westinghouse Motor Company

OL_P1254 Model (1) - TECO-Westinghouse Motor Company

OL_P1254 Model (1) - TECO-Westinghouse Motor Company

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

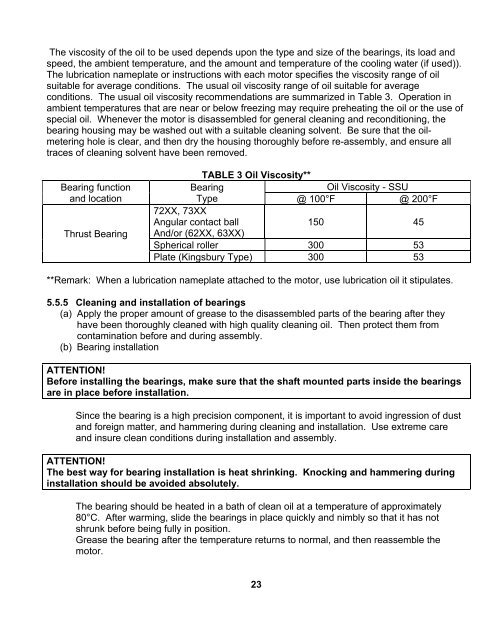

The viscosity of the oil to be used depends upon the type and size of the bearings, its load andspeed, the ambient temperature, and the amount and temperature of the cooling water (if used)).The lubrication nameplate or instructions with each motor specifies the viscosity range of oilsuitable for average conditions. The usual oil viscosity range of oil suitable for averageconditions. The usual oil viscosity recommendations are summarized in Table 3. Operation inambient temperatures that are near or below freezing may require preheating the oil or the use ofspecial oil. Whenever the motor is disassembled for general cleaning and reconditioning, thebearing housing may be washed out with a suitable cleaning solvent. Be sure that the oilmeteringhole is clear, and then dry the housing thoroughly before re-assembly, and ensure alltraces of cleaning solvent have been removed.Bearing functionand locationThrust BearingTABLE 3 Oil Viscosity**BearingOil Viscosity - SSUType @ 100°F @ 200°F72XX, 73XXAngular contact ball150 45And/or (62XX, 63XX)Spherical roller 300 53Plate (Kingsbury Type) 300 53**Remark: When a lubrication nameplate attached to the motor, use lubrication oil it stipulates.5.5.5 Cleaning and installation of bearings(a) Apply the proper amount of grease to the disassembled parts of the bearing after theyhave been thoroughly cleaned with high quality cleaning oil. Then protect them fromcontamination before and during assembly.(b) Bearing installationATTENTION!Before installing the bearings, make sure that the shaft mounted parts inside the bearingsare in place before installation.Since the bearing is a high precision component, it is important to avoid ingression of dustand foreign matter, and hammering during cleaning and installation. Use extreme careand insure clean conditions during installation and assembly.ATTENTION!The best way for bearing installation is heat shrinking. Knocking and hammering duringinstallation should be avoided absolutely.The bearing should be heated in a bath of clean oil at a temperature of approximately80°C. After warming, slide the bearings in place quickly and nimbly so that it has notshrunk before being fully in position.Grease the bearing after the temperature returns to normal, and then reassemble themotor.23