OL_P1254 Model (1) - TECO-Westinghouse Motor Company

OL_P1254 Model (1) - TECO-Westinghouse Motor Company

OL_P1254 Model (1) - TECO-Westinghouse Motor Company

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

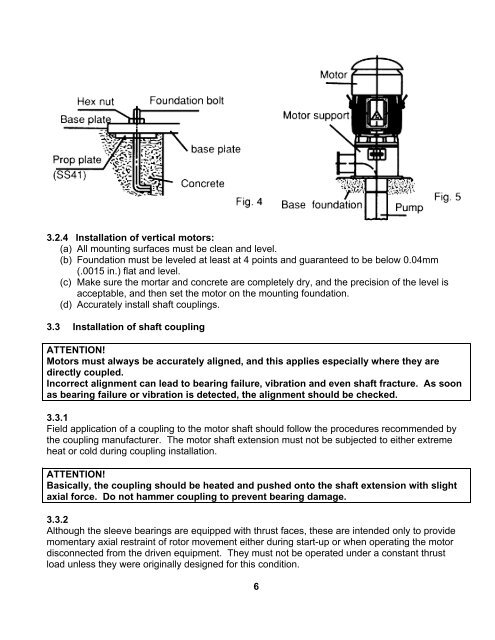

3.2.4 Installation of vertical motors:(a) All mounting surfaces must be clean and level.(b) Foundation must be leveled at least at 4 points and guaranteed to be below 0.04mm(.0015 in.) flat and level.(c) Make sure the mortar and concrete are completely dry, and the precision of the level isacceptable, and then set the motor on the mounting foundation.(d) Accurately install shaft couplings.3.3 Installation of shaft couplingATTENTION!<strong>Motor</strong>s must always be accurately aligned, and this applies especially where they aredirectly coupled.Incorrect alignment can lead to bearing failure, vibration and even shaft fracture. As soonas bearing failure or vibration is detected, the alignment should be checked.3.3.1Field application of a coupling to the motor shaft should follow the procedures recommended bythe coupling manufacturer. The motor shaft extension must not be subjected to either extremeheat or cold during coupling installation.ATTENTION!Basically, the coupling should be heated and pushed onto the shaft extension with slightaxial force. Do not hammer coupling to prevent bearing damage.3.3.2Although the sleeve bearings are equipped with thrust faces, these are intended only to providemomentary axial restraint of rotor movement either during start-up or when operating the motordisconnected from the driven equipment. They must not be operated under a constant thrustload unless they were originally designed for this condition.6