Value added fish by-products - Nordic Innovation

Value added fish by-products - Nordic Innovation

Value added fish by-products - Nordic Innovation

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

The results shows that from a production of 60.000 tons a year, 1.200 tons will be lost with<br />

the processing water. The process developed in this study can increase the yield of <strong>fish</strong><br />

muscle for human consumption of 0.2% with regard to gutted <strong>fish</strong>, but 0.4% with regard to<br />

product quantity. However, tests on different collection/filtering methods (vibration sieve,<br />

convey band, and screw press) indicate that the recovery cost of the material in the processing<br />

water does not overcome the benefit. Furthermore, the process requires high usage of water<br />

(about 1 kg per 1 kg fillet), thus it might only be interesting in countries were water is<br />

relatively cheap.<br />

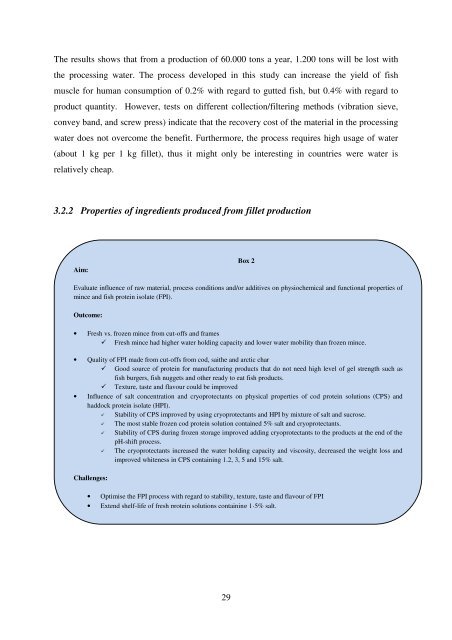

3.2.2 Properties of ingredients produced from fillet production<br />

Aim:<br />

29<br />

Box 2<br />

Evaluate influence of raw material, process conditions and/or additives on physiochemical and functional properties of<br />

mince and <strong>fish</strong> protein isolate (FPI).<br />

Outcome:<br />

• Fresh vs. frozen mince from cut-offs and frames<br />

� Fresh mince had higher water holding capacity and lower water mobility than frozen mince.<br />

• Quality of FPI made from cut-offs from cod, saithe and arctic char<br />

� Good source of protein for manufacturing <strong>products</strong> that do not need high level of gel strength such as<br />

<strong>fish</strong> burgers, <strong>fish</strong> nuggets and other ready to eat <strong>fish</strong> <strong>products</strong>.<br />

� Texture, taste and flavour could be improved<br />

• Influence of salt concentration and cryoprotectants on physical properties of cod protein solutions (CPS) and<br />

haddock protein isolate (HPI).<br />

� Stability of CPS improved <strong>by</strong> using cryoprotectants and HPI <strong>by</strong> mixture of salt and sucrose.<br />

� The most stable frozen cod protein solution contained 5% salt and cryoprotectants.<br />

� Stability of CPS during frozen storage improved adding cryoprotectants to the <strong>products</strong> at the end of the<br />

pH-shift process.<br />

� The cryoprotectants increased the water holding capacity and viscosity, decreased the weight loss and<br />

improved whiteness in CPS containing 1.2, 3, 5 and 15% salt.<br />

Challenges:<br />

• Optimise the FPI process with regard to stability, texture, taste and flavour of FPI<br />

• Extend shelf-life of fresh protein solutions containing 1-5% salt.