Fire ventilation

Fire ventilation

Fire ventilation

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

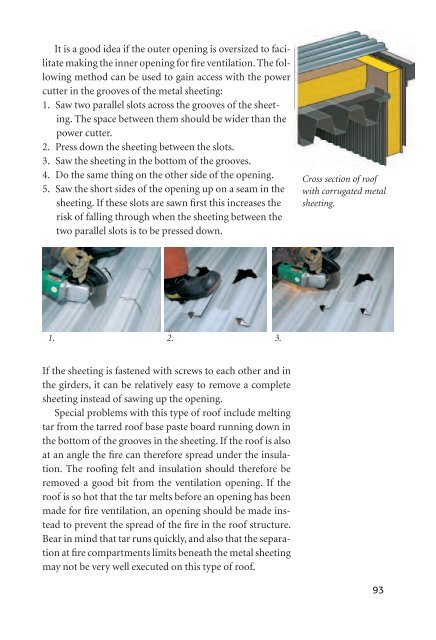

It is a good idea if the outer opening is oversized to facilitatemaking the inner opening for fire <strong>ventilation</strong>. The followingmethod can be used to gain access with the powercutter in the grooves of the metal sheeting:1. Saw two parallel slots across the grooves of the sheeting.The space between them should be wider than thepower cutter.2. Press down the sheeting between the slots.3. Saw the sheeting in the bottom of the grooves.4. Do the same thing on the other side of the opening.5. Saw the short sides of the opening up on a seam in thesheeting. If these slots are sawn first this increases therisk of falling through when the sheeting between thetwo parallel slots is to be pressed down.Cross section of roofwith corrugated metalsheeting.1. 2. 3.If the sheeting is fastened with screws to each other and inthe girders, it can be relatively easy to remove a completesheeting instead of sawing up the opening.Special problems with this type of roof include meltingtar from the tarred roof base paste board running down inthe bottom of the grooves in the sheeting. If the roof is alsoat an angle the fire can therefore spread under the insulation.The roofing felt and insulation should therefore beremoved a good bit from the <strong>ventilation</strong> opening. If theroof is so hot that the tar melts before an opening has beenmade for fire <strong>ventilation</strong>, an opening should be made insteadto prevent the spread of the fire in the roof structure.Bear in mind that tar runs quickly, and also that the separationat fire compartments limits beneath the metal sheetingmay not be very well executed on this type of roof.93