Cover Story ACOusTiCs - Rieter

Cover Story ACOusTiCs - Rieter

Cover Story ACOusTiCs - Rieter

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Cover</strong> story <strong>ACOusTiCs</strong><br />

Temperature after 15 hours<br />

2 °C<br />

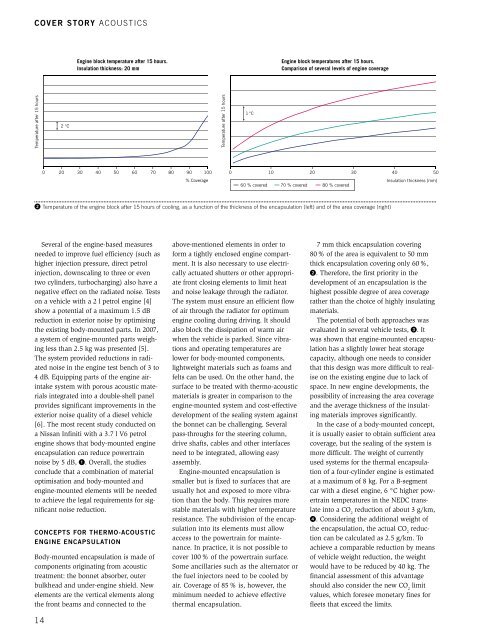

Engine block temperature after 15 hours.<br />

Insulation thickness: 20 mm<br />

0 20 30 40 50 60 70 80 90 100<br />

Several of the engine-based measures<br />

needed to improve fuel efficiency (such as<br />

higher injection pressure, direct petrol<br />

injection, downscaling to three or even<br />

two cylinders, turbocharging) also have a<br />

negative effect on the radiated noise. Tests<br />

on a vehicle with a 2 l petrol engine [4]<br />

show a potential of a maximum 1.5 dB<br />

reduction in exterior noise by optimising<br />

the existing body-mounted parts. In 2007,<br />

a system of engine-mounted parts weighing<br />

less than 2.5 kg was presented [5].<br />

The system provided reductions in radiated<br />

noise in the engine test bench of 3 to<br />

4 dB. Equipping parts of the engine airintake<br />

system with porous acoustic materials<br />

integrated into a double-shell panel<br />

provides significant improvements in the<br />

exterior noise quality of a diesel vehicle<br />

[6]. The most recent study conducted on<br />

a Nissan Infiniti with a 3.7 l V6 petrol<br />

engine shows that body-mounted engine<br />

encapsulation can reduce powertrain<br />

noise by 5 dB, 1. Overall, the studies<br />

conclude that a combination of material<br />

optimisation and body-mounted and<br />

engine-mounted elements will be needed<br />

to achieve the legal requirements for significant<br />

noise reduction.<br />

ConCePts For tHermo-aCoustiC<br />

engine enCaPsuLation<br />

Body-mounted encapsulation is made of<br />

components originating from acoustic<br />

treatment: the bonnet absorber, outer<br />

bulkhead and under-engine shield. New<br />

elements are the vertical elements along<br />

the front beams and connected to the<br />

% <strong>Cover</strong>age<br />

Temperature after 15 hours<br />

1 °C<br />

above-mentioned elements in order to<br />

form a tightly enclosed engine compartment.<br />

It is also necessary to use electrically<br />

actuated shutters or other appropriate<br />

front closing elements to limit heat<br />

and noise leakage through the radiator.<br />

The system must ensure an efficient flow<br />

of air through the radiator for optimum<br />

engine cooling during driving. It should<br />

also block the dissipation of warm air<br />

when the vehicle is parked. Since vibrations<br />

and operating temperatures are<br />

lower for body-mounted components,<br />

lightweight materials such as foams and<br />

felts can be used. On the other hand, the<br />

surface to be treated with thermo-acoustic<br />

materials is greater in comparison to the<br />

engine-mounted system and cost-effective<br />

development of the sealing system against<br />

the bonnet can be challenging. Several<br />

pass-throughs for the steering column,<br />

drive shafts, cables and other interfaces<br />

need to be integrated, allowing easy<br />

assembly.<br />

Engine-mounted encapsulation is<br />

smaller but is fixed to surfaces that are<br />

usually hot and exposed to more vibration<br />

than the body. This requires more<br />

stable materials with higher temperature<br />

resistance. The subdivision of the encapsulation<br />

into its elements must allow<br />

access to the powertrain for maintenance.<br />

In practice, it is not possible to<br />

cover 100 % of the powertrain surface.<br />

Some ancillaries such as the alternator or<br />

the fuel injectors need to be cooled by<br />

air. <strong>Cover</strong>age of 85 % is, however, the<br />

minimum needed to achieve effective<br />

thermal encapsulation.<br />

Engine block temperatures after 15 hours.<br />

Comparison of several levels of engine coverage<br />

0 10 20 30 40 50<br />

60 % covered 70 % covered 80 % covered<br />

2 Temperature of the engine block after 15 hours of cooling, as a function of the thickness of the encapsulation (left) and of the area coverage (right)<br />

14<br />

Insulation thickness [mm]<br />

7 mm thick encapsulation covering<br />

80 % of the area is equivalent to 50 mm<br />

thick encapsulation covering only 60 %,<br />

2. Therefore, the first priority in the<br />

development of an encapsulation is the<br />

highest possible degree of area coverage<br />

rather than the choice of highly insulating<br />

materials.<br />

The potential of both approaches was<br />

evaluated in several vehicle tests, 3. It<br />

was shown that engine-mounted encapsulation<br />

has a slightly lower heat storage<br />

capacity, although one needs to consider<br />

that this design was more difficult to realise<br />

on the existing engine due to lack of<br />

space. In new engine developments, the<br />

possibility of increasing the area coverage<br />

and the average thickness of the insulating<br />

materials improves significantly.<br />

In the case of a body-mounted concept,<br />

it is usually easier to obtain sufficient area<br />

coverage, but the sealing of the system is<br />

more difficult. The weight of currently<br />

used systems for the thermal encapsulation<br />

of a four-cylinder engine is estimated<br />

at a maximum of 8 kg. For a B-segment<br />

car with a diesel engine, 6 °C higher powertrain<br />

temperatures in the NEDC translate<br />

into a CO 2 reduction of about 3 g/km,<br />

4. Considering the additional weight of<br />

the encapsulation, the actual CO 2 reduction<br />

can be calculated as 2.5 g/km. To<br />

achieve a comparable reduction by means<br />

of vehicle weight reduction, the weight<br />

would have to be reduced by 40 kg. The<br />

financial assessment of this advantage<br />

should also consider the new CO 2 limit<br />

values, which foresee monetary fines for<br />

fleets that exceed the limits.