Solutions for the Global Metals Industry

Solutions for the Global Metals Industry

Solutions for the Global Metals Industry

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

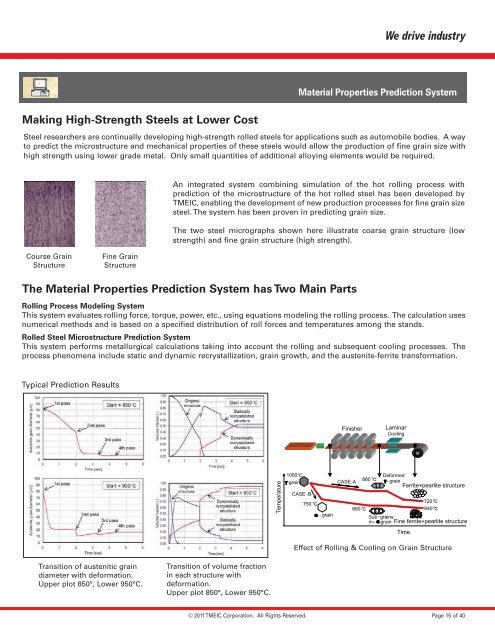

Material Properties Prediction SystemMaking High-Strength Steels at Lower CostSteel researchers are continually developing high-strength rolled steels <strong>for</strong> applications such as automobile bodies. A wayto predict <strong>the</strong> microstructure and mechanical properties of <strong>the</strong>se steels would allow <strong>the</strong> production of fine grain size withhigh strength using lower grade metal. Only small quantities of additional alloying elements would be required.An integrated system combining simulation of <strong>the</strong> hot rolling process withprediction of <strong>the</strong> microstructure of <strong>the</strong> hot rolled steel has been developed byTMEIC, enabling <strong>the</strong> development of new production processes <strong>for</strong> fine grain sizesteel. The system has been proven in predicting grain size.The two steel micrographs shown here illustrate coarse grain structure (lowstrength) and fine grain structure (high strength).Course GrainStructureFine GrainStructureThe Material Properties Prediction System has Two Main PartsRolling Process Modeling SystemThis system evaluates rolling <strong>for</strong>ce, torque, power, etc., using equations modeling <strong>the</strong> rolling process. The calculation usesnumerical methods and is based on a specified distribution of roll <strong>for</strong>ces and temperatures among <strong>the</strong> stands.Rolled Steel Microstructure Prediction SystemThis system per<strong>for</strong>ms metallurgical calculations taking into account <strong>the</strong> rolling and subsequent cooling processes. Theprocess phenomena include static and dynamic recrystallization, grain growth, and <strong>the</strong> austenite-ferrite trans<strong>for</strong>mation.Typical Prediction ResultsFinisherLaminarCoolingTemperature1050-grainCASE -B750 -grainCASE-A680880 De<strong>for</strong>med- grainFerrite+pearlite structure720640Sub- grainsin- grain Fine ferrite+pearlite structureTimeEffect of Rolling & Cooling on Grain StructureTransition of austenitic graindiameter with de<strong>for</strong>mation.Upper plot 850°, Lower 950°C.Transition of volume fractionin each structure withde<strong>for</strong>mation.Upper plot 850°, Lower 950°C.© 2011 TMEIC Corporation. All Rights Reserved.Page 15 of 40