Solutions for the Global Metals Industry

Solutions for the Global Metals Industry

Solutions for the Global Metals Industry

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

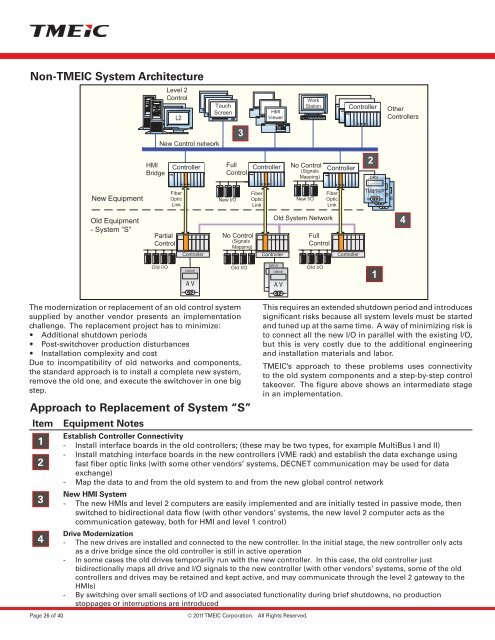

Non-TMEIC System ArchitectureLevel 2ControlL2TouchScrTouchScr eeneen TouchScreenHMIViewerWorkStationControllerO<strong>the</strong>rControllersNew Control network3New EquipmentHMIBridgeControllerFiberOpticLinkFullControlNew I/OControllerFiberOpticLinkNo Control(SignalsMapping)New I/OControllerFiberOpticLink2DRVDRVDRVTMdrive®TMdriveTMdriveOld Equipment- System “S”PartialControlControllerNo Control(SignalsMapping)ControllerOld System NetworkFullControlController4Old I/ODRIVEA VOld I/ODRIVEDRIVEA VA VOld I/O1The modernization or replacement of an old control systemsupplied by ano<strong>the</strong>r vendor presents an implementationchallenge. The replacement project has to minimize:• Additional shutdown periods• Post-switchover production disturbances• Installation complexity and costDue to incompatibility of old networks and components,<strong>the</strong> standard approach is to install a complete new system,remove <strong>the</strong> old one, and execute <strong>the</strong> switchover in one bigstep.Approach to Replacement of System “S”Item1234Page 26 of 40Equipment NotesEstablish Controller Connectivity- Install interface boards in <strong>the</strong> old controllers; (<strong>the</strong>se may be two types, <strong>for</strong> example MultiBus I and II)- Install matching interface boards in <strong>the</strong> new controllers (VME rack) and establish <strong>the</strong> data exchange usingfast fiber optic links (with some o<strong>the</strong>r vendors’ systems, DECNET communication may be used <strong>for</strong> dataexchange)- Map <strong>the</strong> data to and from <strong>the</strong> old system to and from <strong>the</strong> new global control networkNew HMI System- The new HMIs and level 2 computers are easily implemented and are initially tested in passive mode, <strong>the</strong>nswitched to bidirectional data flow (with o<strong>the</strong>r vendors’ systems, <strong>the</strong> new level 2 computer acts as <strong>the</strong>communication gateway, both <strong>for</strong> HMI and level 1 control)Drive Modernization- The new drives are installed and connected to <strong>the</strong> new controller. In <strong>the</strong> initial stage, <strong>the</strong> new controller only actsas a drive bridge since <strong>the</strong> old controller is still in active operation- In some cases <strong>the</strong> old drives temporarily run with <strong>the</strong> new controller. In this case, <strong>the</strong> old controller justbidirectionally maps all drive and I/O signals to <strong>the</strong> new controller (with o<strong>the</strong>r vendors’ systems, some of <strong>the</strong> oldcontrollers and drives may be retained and kept active, and may communicate through <strong>the</strong> level 2 gateway to <strong>the</strong>HMIs)- By switching over small sections of I/O and associated functionality during brief shutdowns, no productionstoppages or interruptions are introduced© 2011 TMEIC Corporation. All Rights Reserved.This requires an extended shutdown period and introducessignificant risks because all system levels must be startedand tuned up at <strong>the</strong> same time. A way of minimizing risk isto connect all <strong>the</strong> new I/O in parallel with <strong>the</strong> existing I/O,but this is very costly due to <strong>the</strong> additional engineeringand installation materials and labor.TMEIC’s approach to <strong>the</strong>se problems uses connectivityto <strong>the</strong> old system components and a step-by-step controltakeover. The figure above shows an intermediate stagein an implementation.