Solutions for the Global Metals Industry

Solutions for the Global Metals Industry

Solutions for the Global Metals Industry

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

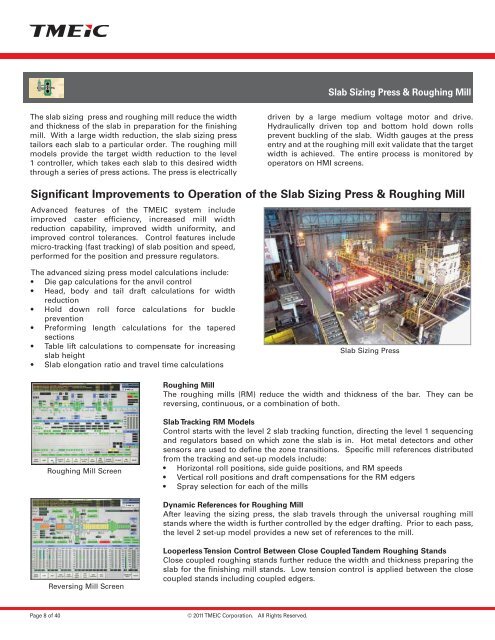

Slab Sizing Press & Roughing MillThe slab sizing press and roughing mill reduce <strong>the</strong> widthand thickness of <strong>the</strong> slab in preparation <strong>for</strong> <strong>the</strong> finishingmill. With a large width reduction, <strong>the</strong> slab sizing presstailors each slab to a particular order. The roughing millmodels provide <strong>the</strong> target width reduction to <strong>the</strong> level1 controller, which takes each slab to this desired widththrough a series of press actions. The press is electricallydriven by a large medium voltage motor and drive.Hydraulically driven top and bottom hold down rollsprevent buckling of <strong>the</strong> slab. Width gauges at <strong>the</strong> pressentry and at <strong>the</strong> roughing mill exit validate that <strong>the</strong> targetwidth is achieved. The entire process is monitored byoperators on HMI screens.Significant Improvements to Operation of <strong>the</strong> Slab Sizing Press & Roughing MillAdvanced features of <strong>the</strong> TMEIC system includeimproved caster efficiency, increased mill widthreduction capability, improved width uni<strong>for</strong>mity, andimproved control tolerances. Control features includemicro-tracking (fast tracking) of slab position and speed,per<strong>for</strong>med <strong>for</strong> <strong>the</strong> position and pressure regulators.The advanced sizing press model calculations include:• Die gap calculations <strong>for</strong> <strong>the</strong> anvil control• Head, body and tail draft calculations <strong>for</strong> widthreduction• Hold down roll <strong>for</strong>ce calculations <strong>for</strong> buckleprevention• Pre<strong>for</strong>ming length calculations <strong>for</strong> <strong>the</strong> taperedsections• Table lift calculations to compensate <strong>for</strong> increasingslab height• Slab elongation ratio and travel time calculationsSlab Sizing PressRoughing MillThe roughing mills (RM) reduce <strong>the</strong> width and thickness of <strong>the</strong> bar. They can bereversing, continuous, or a combination of both.Roughing Mill ScreenSlab Tracking RM ModelsControl starts with <strong>the</strong> level 2 slab tracking function, directing <strong>the</strong> level 1 sequencingand regulators based on which zone <strong>the</strong> slab is in. Hot metal detectors and o<strong>the</strong>rsensors are used to define <strong>the</strong> zone transitions. Specific mill references distributedfrom <strong>the</strong> tracking and set-up models include:• Horizontal roll positions, side guide positions, and RM speeds• Vertical roll positions and draft compensations <strong>for</strong> <strong>the</strong> RM edgers• Spray selection <strong>for</strong> each of <strong>the</strong> millsDynamic References <strong>for</strong> Roughing MillAfter leaving <strong>the</strong> sizing press, <strong>the</strong> slab travels through <strong>the</strong> universal roughing millstands where <strong>the</strong> width is fur<strong>the</strong>r controlled by <strong>the</strong> edger drafting. Prior to each pass,<strong>the</strong> level 2 set-up model provides a new set of references to <strong>the</strong> mill.Reversing Mill ScreenLooperless Tension Control Between Close Coupled Tandem Roughing StandsClose coupled roughing stands fur<strong>the</strong>r reduce <strong>the</strong> width and thickness preparing <strong>the</strong>slab <strong>for</strong> <strong>the</strong> finishing mill stands. Low tension control is applied between <strong>the</strong> closecoupled stands including coupled edgers.Page 8 of 40© 2011 TMEIC Corporation. All Rights Reserved.