LDS 3000 data sheet.pdf - Siemens

LDS 3000 data sheet.pdf - Siemens

LDS 3000 data sheet.pdf - Siemens

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

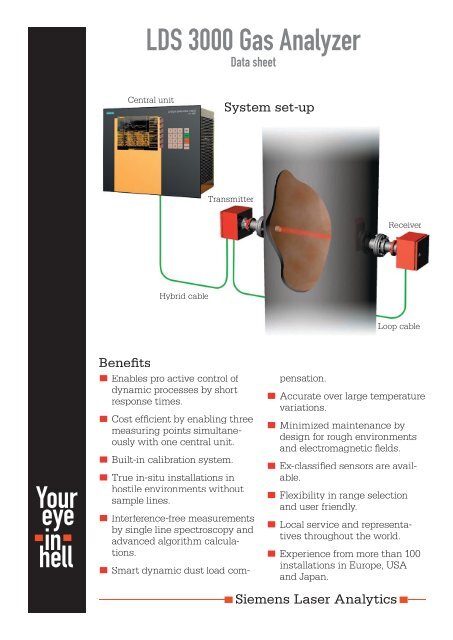

<strong>LDS</strong> <strong>3000</strong> Gas AnalyzerData <strong>sheet</strong>Central unitSystem set-upTransmitterReceiverHybrid cableLoop cableYoureyeinhellBenefits• Enables pro active control ofdynamic processes by shortresponse times.• Cost efficient by enabling threemeasuring points simultaneouslywith one central unit.• Built-in calibration system.• True in-situ installations inhostile environments withoutsample lines.• Interference-free measurementsby single line spectroscopy andadvanced algorithm calculations.• Smart dynamic dust load compensation.• Accurate over large temperaturevariations.• Minimized maintenance bydesign for rough environmentsand electromagnetic fields.• Ex-classified sensors are available.• Flexibility in range selectionand user friendly.• Local service and representativesthroughout the world.• Experience from more than 100installations in Europe, USAand Japan.<strong>Siemens</strong> Laser Analytics

<strong>LDS</strong> <strong>3000</strong> – Data <strong>sheet</strong>Measurements – generalAccuracyBetter than 2% of readingLinearity Better than 1%StabilityBetter than three times the resolutionCross sensitivity Better than the resolutionResolution/response timeThese specifications strongly depend on the measurementenvironments like dust load, temperature fl uctuations, etc.These parameters are usually better than listed but insome extreme cases they can even be slightly worse. Thereare also a trade off between resolution and response time.You can calculate the actual resolution by dividing theresolution given below with the path length in meters.Gas/application Resolution • 1 m Response timeNH 3 – SCR ~0.6 ppm 1 – 30 sec *NH 3 – SNCR ~1 ppm > 1 secNH 3 – Heavy vehicle ~1 ppm > 1 secO 2 – Combustion control ~1% 1 – 2 secCO 2 – Combustion control ~1% 1 – 2 secH 2 O – Combustion control ~1% 1 – 2 secHCl – Combustion control ~4 ppm 1 – 2 secTemp. – Combustion control ~20 °C 1 – 2 secHCl – Filter optimization ~1 ppm 1 – 3 secHF – Filter optimization ~0.4 ppm 1 – 3 secCO – ESP ~0.5% < 1 secNH 3 – Emission ~0.5 ppm < 10 secHCl – Emission ~0.3 ppm < 10 secHF – Emission ~0.1 ppm < 10 sec* Depending on dust loadThe Central Unit CU <strong>3000</strong>All critical components are housed in the central unit andit can be placed several hundred meters away from themeasurement point.DimensionsWeightPower consumptionPower supplyAmbient temperatureDust and humidityDisplayControlAnalog outputsAnalog inputsAlarmMediaCommunicationH: 399 mm x W: 483 mm (19”) x D: 390 mm.30 kg (66 lb.)150 W85 - 264 VAC, 50/60 Hz, 200 VA+10 °C to +30 °C (+50 °F to +86 °F)Free from dust and a non condensing relativehu midity of 0-80%.Graphic VGA displayMenu driven key pad and numeric key pad.Isolated active 4-20 mAIsolated 4-20 mA4 relay outputs.PC-card (PCMCIA)RS232 serial portHybrid Cable FC <strong>3000</strong>Two optical fi bres and two electrical wires for 24 VDC inone cable. (The loop cable intercon necting the sensor pairdoes not contain the single mode fi bre).Connector SM fi berConnector MM fi berJacket materialDimensionAmbient temperatureImpact resistanceMax tensile strengthMinimum bend radiusE2000 angle polishedSMAGreen, oil resistant polyurethaneDiameter: