Download File - Hawk Measurement Systems!

Download File - Hawk Measurement Systems!

Download File - Hawk Measurement Systems!

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

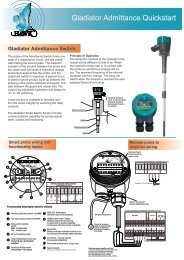

Microwave Pulse Switch - Presence & Absence DetectionMANUALRev 1.0MountingGeneral Guidelines1. The microwave beam is a polarized form of energy.As such, it is necessary to align the units in the samespatial plane. If the units do not have the same orientationthe amount of received energy is diminished. At 90°to each other, the detector is blind and cannot detect thebeam. The actual angle of mounting is not relevant, solong as both the MPS & MPR have the same angle andelevation.See figure B.2. When looking for a mounting location, try to locateand mount the units flush and where minimal buildupwill occur. The system can penetrate through generousamounts of buildup of various products; however, thebetter the position, the more reliable it will operate.3. The systems energy cannot penetrate through steellinings or other conductive linings. You must cut a viewingwindow and use an appropriate weldment.4. For high vibration applications, it is necessary to isolatethe electronics to keep them from being damaged.This is accomplished using the optional 4” UHMW or teflonwindows. The microwave sender and receiver shouldbe mounted to a stable structure (I-beam, handrail) toisolate them from the vibration. Isolation shock mountscan also be provided to help isolate the electronics.See Figure C.5. For applications which exceed 140 degrees Fahrenheit(precipitators, cement cyclones, etc.), it is necessaryto use remote mounting microwaves with waveguideassemblies. This allows the electronics to be placed inan area where ambient temperatures do not exceedthe maximum allowable temperature for the electronics.Firebrick and ceramic windows are best suited for hightemperature applications. It is necessary to contact thefactory for this type of application, however, Figure D isprovidedas a general guideline for such applications.MDS Doppler System1. Mount the MDS in an area where the product flow is tobe monitored.2. Ensure there is low vibration on the mounting if theproduct flow is low.3/ Mount the MDR sender-receiver in a position wherestationary material will not build upon the sensor face.Ensure the face of the sensor is flush with the inside ofthe flow chamber. (if used in a closed environment)4. Correctly wire the MDR to the MDA as per the connectiondiagram. If extension cableis used, S and T aresingle cables. The remainder are all then combined toform a solid ground connection back to terminal labelledP.5. RV1 and RV2 must be adjusted together with thepotentiometer positional arrows both basically alignedin the same direction. They are parallel potentiometers.Begin at minimum anti-clockwise position.6. Position Lo-Hi slide switch to low position.7. Apply power to the unit. The green LED LD1 will beilluminated.8. When material is flowing at normal speed, slowly increaseRV1 and then RV2, then RV1 then RV2 etc. untilflow is detected. Flow is detected when the Red LEDLD2 is illuminated.9. The yellow LED, LD3 will be illuminated when therelay becomes energised.10. The relay energisation is timed via an ON delay andOFF delay potentiometers ON delay is the delay whenLD2 is constantly illuminated prior to the relay pulling in.When LD2 is no longer illuminated (i.e. no flow) the delaybefore the relay switches off is controlled by the OFFdelay potentiometer.11. When LD2 is illuminated increase RV1 and RV2 by afurther 15% (approx.) of the adjusted distance from thezero position. This allows for some variation in the flowindeed - the larger the percentage used the greater theflow change needed before the relay switches.12. Intermittent flow surges can be removed via the ONdelay OFF delay potentiometers13. If you increase RV1 and RV2 to maximum and LD2is not illuminated, decrease anti-clockwise back to zero.Slide the slide switch LO-HI to the Hi position and repeatthe slow step by step adjustment of RV 1 and RV2.Sultan 234 SeriesIf possible stop the flow to ensure the sensitivity (RV1and RV2) are set correctly. The time delays can bechecked without stopping the flow of the material. Thepush button on the RHS of the board is a press to testpush button. This simulates no received flow signal andconsequently you can adjust your on and off delays.13Microwave Series