Palair Plus - Ingersoll Rand Industrial Technologies On-line ...

Palair Plus - Ingersoll Rand Industrial Technologies On-line ...

Palair Plus - Ingersoll Rand Industrial Technologies On-line ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

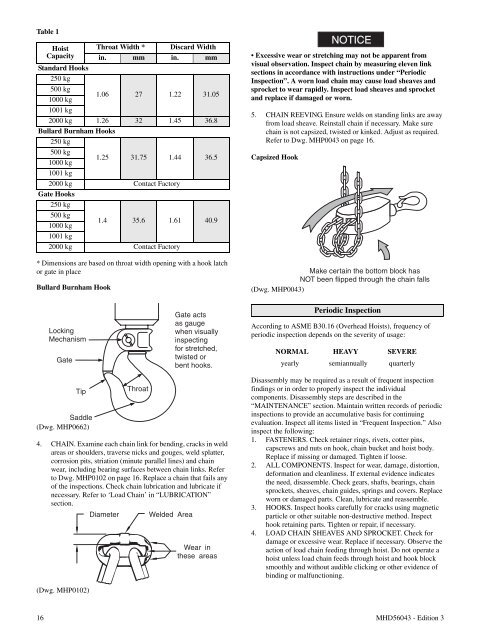

Table 1HoistCapacityStandard Hooks250 kgThroatWidth* DiscardWidthin. mm in. mm500 kg1000 kg1001 kg2000 kg1.061.2627321.221.4531.0536.8Bullard Burnham Hooks250 kg500 kg1000 kg1001 kg1.25 31.75 1.44 36.52000 kg Contact FactoryGate Hooks250 kg500 kg1000 kg1001 kg1.4 35.6 1.61 40.92000 kg Contact FactoryNOTICE• Excessive wear or stretching may not be apparent fromvisual observation. Inspect chain by measuring eleven linksections in accordance with instructions under “PeriodicInspection”. A worn load chain may cause load sheaves andsprocket to wear rapidly. Inspect load sheaves and sprocketand replace if damaged or worn.5. CHAIN REEVING. Ensure welds on standing links are awayfrom load sheave. Reinstall chain if necessary. Make surechain is not capsized, twisted or kinked. Adjust as required.Refer to Dwg. MHP0043 on page 16.Capsized Hook* Dimensions are based on throat width opening with a hook latchor gate in placeBullard Burnham Hook(Dwg. MHP0043)Periodic InspectionAccording to ASME B30.16 (Overhead Hoists), frequency ofperiodic inspection depends on the severity of usage:NORMAL HEAVY SEVEREyearly semiannually quarterly(Dwg. MHP0662)4. CHAIN. Examine each chain link for bending, cracks in weldareas or shoulders, traverse nicks and gouges, weld splatter,corrosion pits, striation (minute parallel <strong>line</strong>s) and chainwear, including bearing surfaces between chain links. Referto Dwg. MHP0102 on page 16. Replace a chain that fails anyof the inspections. Check chain lubrication and lubricate ifnecessary. Refer to ‘Load Chain’ in “LUBRICATION”section.Disassembly may be required as a result of frequent inspectionfindings or in order to properly inspect the individualcomponents. Disassembly steps are described in the“MAINTENANCE” section. Maintain written records of periodicinspections to provide an accumulative basis for continuingevaluation. Inspect all items listed in “Frequent Inspection.” Alsoinspect the following:1. FASTENERS. Check retainer rings, rivets, cotter pins,capscrews and nuts on hook, chain bucket and hoist body.Replace if missing or damaged. Tighten if loose.2. ALL COMPONENTS. Inspect for wear, damage, distortion,deformation and clean<strong>line</strong>ss. If external evidence indicatesthe need, disassemble. Check gears, shafts, bearings, chainsprockets, sheaves, chain guides, springs and covers. Replaceworn or damaged parts. Clean, lubricate and reassemble.3. HOOKS. Inspect hooks carefully for cracks using magneticparticle or other suitable non-destructive method. Inspecthook retaining parts. Tighten or repair, if necessary.4. LOAD CHAIN SHEAVES AND SPROCKET. Check fordamage or excessive wear. Replace if necessary. Observe theaction of load chain feeding through hoist. Do not operate ahoist unless load chain feeds through hoist and hook blocksmoothly and without audible clicking or other evidence ofbinding or malfunctioning.(Dwg. MHP0102)16 MHD56043 - Edition 3