Palair Plus - Ingersoll Rand Industrial Technologies On-line ...

Palair Plus - Ingersoll Rand Industrial Technologies On-line ...

Palair Plus - Ingersoll Rand Industrial Technologies On-line ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

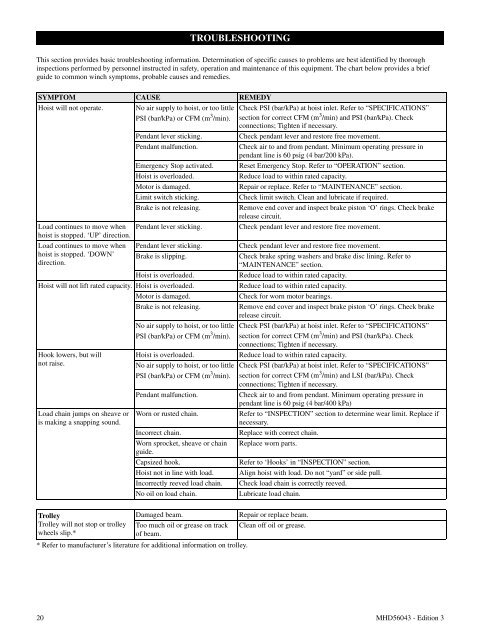

TROUBLESHOOTINGThis section provides basic troubleshooting information. Determination of specific causes to problems are best identified by thoroughinspections performed by personnel instructed in safety, operation and maintenance of this equipment. The chart below provides a briefguide to common winch symptoms, probable causes and remedies.SYMPTOM CAUSE REMEDYHoist will not operate. No air supply to hoist, or too littlePSI (bar/kPa) or CFM (m 3 /min).Check PSI (bar/kPa) at hoist inlet. Refer to “SPECIFICATIONS”section for correct CFM (m 3 /min) and PSI (bar/kPa). Checkconnections; Tighten if necessary.Pendant lever sticking.Check pendant lever and restore free movement.Pendant malfunction.Check air to and from pendant. Minimum operating pressure inpendant <strong>line</strong> is 60 psig (4 bar/200 kPa).Emergency Stop activated. Reset Emergency Stop. Refer to “OPERATION” section.Hoist is overloaded.Reduce load to within rated capacity.Motor is damaged.Repair or replace. Refer to “MAINTENANCE” section.Limit switch sticking.Check limit switch. Clean and lubricate if required.Brake is not releasing.Remove end cover and inspect brake piston ‘O’ rings. Check brakerelease circuit.Load continues to move whenhoist is stopped. ‘UP’ direction.Pendant lever sticking.Check pendant lever and restore free movement.Load continues to move whenhoist is stopped. ‘DOWN’direction.Pendant lever sticking.Brake is slipping.Hoist is overloaded.Hoist will not lift rated capacity. Hoist is overloaded.Motor is damaged.Brake is not releasing.Hook lowers, but willnot raise.Load chain jumps on sheave oris making a snapping sound.No air supply to hoist, or too littlePSI (bar/kPa) or CFM (m 3 /min).Hoist is overloaded.No air supply to hoist, or too littlePSI (bar/kPa) or CFM (m 3 /min).Pendant malfunction.Worn or rusted chain.Incorrect chain.Worn sprocket, sheave or chainguide.Capsized hook.Hoist not in <strong>line</strong> with load.Incorrectly reeved load chain.No oil on load chain.Check pendant lever and restore free movement.Check brake spring washers and brake disc lining. Refer to“MAINTENANCE” section.Reduce load to within rated capacity.Reduce load to within rated capacity.Check for worn motor bearings.Remove end cover and inspect brake piston ‘O’ rings. Check brakerelease circuit.Check PSI (bar/kPa) at hoist inlet. Refer to “SPECIFICATIONS”section for correct CFM (m 3 /min) and PSI (bar/kPa). Checkconnections; Tighten if necessary.Reduce load to within rated capacity.Check PSI (bar/kPa) at hoist inlet. Refer to “SPECIFICATIONS”section for correct CFM (m 3 /min) and LSI (bar/kPa). Checkconnections; Tighten if necessary.Check air to and from pendant. Minimum operating pressure inpendant <strong>line</strong> is 60 psig (4 bar/400 kPa)Refer to “INSPECTION” section to determine wear limit. Replace ifnecessary.Replace with correct chain.Replace worn parts.Refer to ‘Hooks’ in “INSPECTION” section.Align hoist with load. Do not “yard” or side pull.Check load chain is correctly reeved.Lubricate load chain.TrolleyTrolley will not stop or trolleywheels slip.*Damaged beam.Too much oil or grease on trackof beam.* Refer to manufacturer’s literature for additional information on trolley.Repair or replace beam.Clean off oil or grease.20 MHD56043 - Edition 3