Palair Plus - Ingersoll Rand Industrial Technologies On-line ...

Palair Plus - Ingersoll Rand Industrial Technologies On-line ...

Palair Plus - Ingersoll Rand Industrial Technologies On-line ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

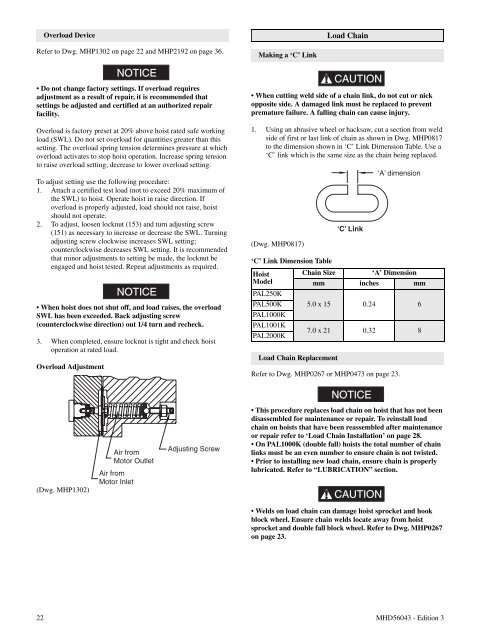

Overload DeviceLoad ChainRefer to Dwg. MHP1302 on page 22 and MHP2192 on page 36.NOTICE• Do not change factory settings. If overload requiresadjustment as a result of repair, it is recommended thatsettings be adjusted and certified at an authorized repairfacility.Overload is factory preset at 20% above hoist rated safe workingload (SWL). Do not set overload for quantities greater than thissetting. The overload spring tension determines pressure at whichoverload activates to stop hoist operation. Increase spring tensionto raise overload setting; decrease to lower overload setting.To adjust setting use the following procedure:1. Attach a certified test load (not to exceed 20% maximum ofthe SWL) to hoist. Operate hoist in raise direction. Ifoverload is properly adjusted, load should not raise, hoistshould not operate.2. To adjust, loosen locknut (153) and turn adjusting screw(151) as necessary to increase or decrease the SWL. Turningadjusting screw clockwise increases SWL setting;counterclockwise decreases SWL setting. It is recommendedthat minor adjustments to setting be made, the locknut beengaged and hoist tested. Repeat adjustments as required.NOTICE• When hoist does not shut off, and load raises, the overloadSWL has been exceeded. Back adjusting screw(counterclockwise direction) out 1/4 turn and recheck.3. When completed, ensure locknut is tight and check hoistoperation at rated load.Overload AdjustmentMakinga‘C’LinkCAUTION• When cutting weld side of a chain link, do not cut or nickopposite side. A damaged link must be replaced to preventpremature failure. A falling chain can cause injury.1. Using an abrasive wheel or hacksaw, cut a section from weldside of first or last link of chain as shown in Dwg. MHP0817to the dimension shown in ‘C’ Link Dimension Table. Use a‘C’ link which is the same size as the chain being replaced.(Dwg. MHP0817)‘C’ Link Dimension TableHoistModelPAL250KPAL500KPAL1000KPAL1001KPAL2000KLoad Chain ReplacementChain Size‘A’ Dimensionmm inches mm5.0x15 0.24 67.0x21 0.32 8RefertoDwg.MHP0267orMHP0473onpage23.NOTICE• This procedure replaces load chain on hoist that has not beendisassembled for maintenance or repair. To reinstall loadchainonhoiststhathavebeenreassembledaftermaintenanceor repair refer to ‘Load Chain Installation’ on page 28.• <strong>On</strong> PAL1000K (double fall) hoists the total number of chainlinks must be an even number to ensure chain is not twisted.• Prior to installing new load chain, ensure chain is properlylubricated. Refer to “LUBRICATION” section.(Dwg. MHP1302)CAUTION• Welds on load chain can damage hoist sprocket and hookblock wheel. Ensure chain welds locate away from hoistsprocket and double fall block wheel. Refer to Dwg. MHP0267on page 23.22 MHD56043 - Edition 3