Palair Plus - Ingersoll Rand Industrial Technologies On-line ...

Palair Plus - Ingersoll Rand Industrial Technologies On-line ...

Palair Plus - Ingersoll Rand Industrial Technologies On-line ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

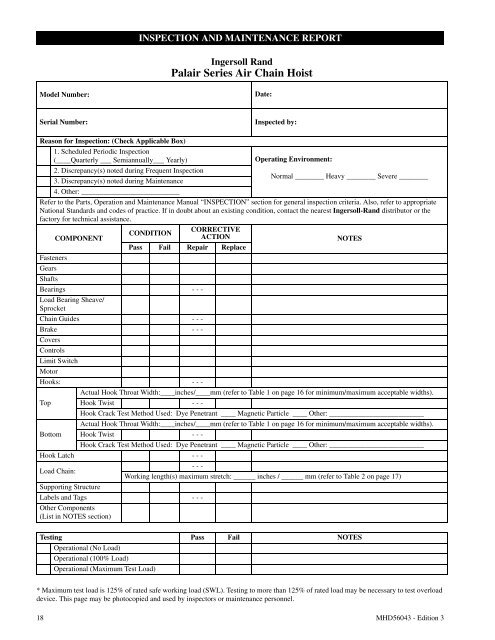

INSPECTION AND MAINTENANCE REPORT<strong>Ingersoll</strong> <strong>Rand</strong><strong>Palair</strong> Series Air Chain HoistModel Number:Date:Serial Number:Inspected by:Reason for Inspection: (Check Applicable Box)1. Scheduled Periodic Inspection(____Quarterly ___ Semiannually___ Yearly)Operating Environment:2. Discrepancy(s) noted during Frequent Inspection3. Discrepancy(s) noted during MaintenanceNormal ________ Heavy ________ Severe ________4. Other: ___________________________Refer to the Parts, Operation and Maintenance Manual “INSPECTION” section for general inspection criteria. Also, refer to appropriateNational Standards and codes of practice. If in doubt about an existing condition, contact the nearest <strong>Ingersoll</strong>-<strong>Rand</strong> distributor or thefactory for technical assistance.CORRECTIVECONDITIONCOMPONENTACTIONNOTESPass Fail Repair ReplaceFastenersGearsShaftsBearings ---Load Bearing Sheave/SprocketChainGuides ---Brake ---CoversControlsLimit SwitchMotorHooks: ---Actual Hook Throat Width:____inches/____mm (refer to Table 1 on page 16 for minimum/maximum acceptable widths).Top HookTwist ---Hook Crack Test Method Used: Dye Penetrant ____ Magnetic Particle ____ Other: __________________________Actual Hook Throat Width:____inches/____mm (refer to Table 1 on page 16 for minimum/maximum acceptable widths).Bottom HookTwist ---Hook Crack Test Method Used: Dye Penetrant ____ Magnetic Particle ____ Other: __________________________HookLatch ---Load Chain:---Working length(s) maximum stretch: ______ inches / ______ mm (refer to Table 2 on page 17)Supporting StructureLabels and Tags - - -Other Components(List in NOTES section)Testing Pass Fail NOTESOperational (No Load)Operational (100% Load)Operational (Maximum Test Load)* Maximum test load is 125% of rated safe working load (SWL). Testing to more than 125% of rated load may be necessary to test overloaddevice. This page may be photocopied and used by inspectors or maintenance personnel.18 MHD56043 - Edition 3