- Page 1 and 2:

MicroLogix 1400ProgrammableControll

- Page 3 and 4:

Summary of ChangesTo help you locat

- Page 5 and 6:

Table of ContentsSummary of Changes

- Page 7 and 8:

Table of Contents 7EQU - EqualNEQ -

- Page 9 and 10:

Table of Contents 9Chapter 18Input

- Page 11 and 12:

Table of Contents 11DLG - Data Log

- Page 13 and 14:

PrefaceRead this preface to familia

- Page 15 and 16:

Chapter 1I/O ConfigurationThis sect

- Page 17 and 18:

I/O Configuration 17MicroLogix 1400

- Page 19 and 20:

I/O Configuration 19WordBit Positio

- Page 21 and 22:

I/O Configuration 21Scaled-for-PID

- Page 23 and 24:

I/O Configuration 231762-OF4 Input

- Page 26 and 27:

26 I/O Configuration1762-IT4 Thermo

- Page 28 and 29:

28 I/O ConfigurationAddressing exam

- Page 30 and 31:

30 I/O ConfigurationInput filtering

- Page 32 and 33:

32 I/O ConfigurationConverting Anal

- Page 34 and 35:

34 I/O ConfigurationRising Edge Beh

- Page 36 and 37:

36 I/O ConfigurationIMPORTANTThe in

- Page 38 and 39:

38 I/O ConfigurationNotes:Publicati

- Page 40 and 41:

40 Controller Memory and File Types

- Page 42 and 43:

42 Controller Memory and File Types

- Page 44 and 45:

44 Controller Memory and File Types

- Page 46 and 47:

46 Controller Memory and File Types

- Page 48 and 49:

48 Controller Memory and File Types

- Page 50 and 51:

50 Controller Memory and File Types

- Page 52 and 53:

52 Controller Memory and File Types

- Page 54 and 55:

54 Controller Memory and File Types

- Page 56 and 57:

56 Controller Memory and File Types

- Page 58 and 59:

56 Function FilesOverviewFunction F

- Page 60 and 61:

58 Function FilesThe real-time cloc

- Page 62 and 63:

60 Function FilesMemory ModuleInfor

- Page 64 and 65:

62 Function FilesLE - Load on Error

- Page 66 and 67:

64 Function FilesGeneral Status Blo

- Page 68 and 69:

66 Function FilesDH-485 Diagnostic

- Page 70 and 71:

68 Function FilesDF1 Half-Duplex Sl

- Page 72 and 73:

70 Function FilesDF1 Radio Modem Di

- Page 74 and 75:

72 Function FilesModbus RTU Slave D

- Page 76 and 77:

74 Function FilesPublication 1766-R

- Page 78 and 79:

76 Function FilesDNP3 Slave Diagnos

- Page 80 and 81:

78 Function FilesActive Node Table

- Page 82 and 83:

80 Function FilesEthernetCommunicat

- Page 84 and 85:

82 Function FilesGeneral Channel St

- Page 86 and 87:

84 Function FilesGeneral Channel St

- Page 88 and 89:

86 Function FilesEthernet Diagnosti

- Page 90 and 91:

88 Function FilesEthernet Diagnosti

- Page 92 and 93:

90 Function FilesNotes:Publication

- Page 94 and 95:

92 Programming Instructions Overvie

- Page 96 and 97:

94 Programming Instructions Overvie

- Page 98 and 99:

96 Programming Instructions Overvie

- Page 100 and 101:

98 Programming Instructions Overvie

- Page 102 and 103:

100 Using the High-Speed Counter an

- Page 104 and 105:

102 Using the High-Speed Counter an

- Page 106 and 107:

104 Using the High-Speed Counter an

- Page 108 and 109:

106 Using the High-Speed Counter an

- Page 110 and 111:

108 Using the High-Speed Counter an

- Page 112 and 113:

110 Using the High-Speed Counter an

- Page 114 and 115:

112 Using the High-Speed Counter an

- Page 116 and 117:

114 Using the High-Speed Counter an

- Page 118 and 119:

116 Using the High-Speed Counter an

- Page 120 and 121:

118 Using the High-Speed Counter an

- Page 122 and 123:

120 Using the High-Speed Counter an

- Page 124 and 125:

122 Using the High-Speed Counter an

- Page 126 and 127:

124 Using the High-Speed Counter an

- Page 128 and 129:

126 Using the High-Speed Counter an

- Page 130 and 131:

128 Using the High-Speed Counter an

- Page 132 and 133:

130 Using the High-Speed Counter an

- Page 134 and 135:

132 Using the High-Speed Counter an

- Page 136 and 137:

134 Using the High-Speed Counter an

- Page 138 and 139:

136 Using the High-Speed Counter an

- Page 140 and 141:

138 Using the High-Speed Counter an

- Page 142 and 143:

140 Using High-Speed Outputs• Acc

- Page 144 and 145:

142 Using High-Speed Outputsstructu

- Page 146 and 147:

144 Using High-Speed OutputsTIPIf t

- Page 148 and 149:

146 Using High-Speed OutputsTIPForc

- Page 150 and 151:

148 Using High-Speed Outputs• Set

- Page 152 and 153:

150 Using High-Speed Outputsinstruc

- Page 154 and 155:

152 Using High-Speed OutputsThe cho

- Page 156 and 157:

154 Using High-Speed OutputsThe PTO

- Page 158 and 159:

156 Using High-Speed Outputs• Set

- Page 160 and 161:

158 Using High-Speed OutputsPulse T

- Page 162 and 163:

160 Using High-Speed OutputsPulse W

- Page 164 and 165:

162 Using High-Speed Outputs• Set

- Page 166 and 167:

164 Using High-Speed OutputsPWMX En

- Page 168 and 169:

166 Using High-Speed OutputsPWMX Ac

- Page 170 and 171:

168 Relay-Type (Bit) InstructionsWh

- Page 172 and 173:

170 Relay-Type (Bit) InstructionsAd

- Page 174 and 175:

172 Relay-Type (Bit) InstructionsTI

- Page 176 and 177:

174 Relay-Type (Bit) InstructionsOS

- Page 178 and 179:

176 Timer and Counter InstructionsT

- Page 180 and 181:

178 Timer and Counter InstructionsT

- Page 182 and 183:

180 Timer and Counter InstructionsT

- Page 184 and 185:

182 Timer and Counter InstructionsH

- Page 186 and 187:

184 Timer and Counter InstructionsC

- Page 188 and 189:

186 Timer and Counter InstructionsR

- Page 190 and 191:

188 Timer and Counter InstructionsN

- Page 192 and 193:

190 Compare InstructionsUsing the C

- Page 194 and 195:

192 Compare InstructionsGRT and LES

- Page 196 and 197:

194 Compare InstructionsMEQ Instruc

- Page 198 and 199:

196 Compare InstructionsNotes:Publi

- Page 200 and 201:

198 Math InstructionsAdvanced Math

- Page 202 and 203:

200 Math InstructionsUpdates to Mat

- Page 204 and 205:

202 Math InstructionsDefinitionsOve

- Page 206 and 207:

204 Math InstructionsConsiderations

- Page 208 and 209:

206 Math InstructionsNEG - NegateNE

- Page 210 and 211:

208 Math InstructionsAddressing Mod

- Page 212 and 213:

210 Math InstructionsSCP Instructio

- Page 214 and 215:

212 Math InstructionsEnter the foll

- Page 216 and 217:

214 Math InstructionsCOS - CosineAB

- Page 218 and 219:

216 Math InstructionsTAN - TangentA

- Page 220 and 221:

218 Math InstructionsThe Math Overf

- Page 222 and 223:

220 Math InstructionsACS - Arc Cosi

- Page 224 and 225:

222 Math InstructionsUse the ATN in

- Page 226 and 227:

224 Math InstructionsEnter the foll

- Page 228 and 229:

226 Math InstructionsThe RAD instru

- Page 230 and 231:

228 Math InstructionsUse the LN ins

- Page 232 and 233:

230 Math InstructionsUse the LOG in

- Page 234 and 235:

232 Math InstructionsUse the XPY in

- Page 236 and 237:

234 Math InstructionsIMPORTANTThe X

- Page 238 and 239:

236 Math InstructionsCPT Instructio

- Page 240 and 241:

238 Application Specific Instructio

- Page 242 and 243:

240 Application Specific Instructio

- Page 244 and 245:

242 Application Specific Instructio

- Page 246 and 247:

244 Conversion InstructionsDCD - De

- Page 248 and 249:

246 Conversion InstructionsMath Sta

- Page 250 and 251:

248 Conversion InstructionsTIPTo co

- Page 252 and 253:

250 Conversion InstructionsTOD - Co

- Page 254 and 255:

252 Conversion InstructionsTODTo BC

- Page 256 and 257:

254 Conversion InstructionsNotes:Pu

- Page 258 and 259:

256 Logical InstructionsAddressing

- Page 260 and 261:

258 Logical InstructionsOR - Logica

- Page 262 and 263:

260 Logical InstructionsNOT - Logic

- Page 264 and 265:

262 Move Instructions• Valid cons

- Page 266 and 267:

264 Move InstructionsMVM - Masked M

- Page 268 and 269:

266 Move InstructionsMath Status Bi

- Page 270 and 271:

268 File InstructionsCPW - Copy Wor

- Page 272 and 273:

270 File InstructionsIMPORTANTYou c

- Page 274 and 275:

272 File InstructionsTIPThe source

- Page 276 and 277:

274 File InstructionsBSL Instructio

- Page 278 and 279:

276 File InstructionsBSR Instructio

- Page 280 and 281:

278 File Instructions• Control -

- Page 282 and 283:

280 File Instructions• Destinatio

- Page 284 and 285:

282 File InstructionsLFL - Last In,

- Page 286 and 287:

284 File InstructionsLFU - Last In,

- Page 288 and 289:

286 File InstructionsSWP - SwapSWPS

- Page 290 and 291:

288 Sequencer InstructionsSQC- Sequ

- Page 292 and 293: 290 Sequencer Instructions.TIPIf ma

- Page 294 and 295: 292 Sequencer InstructionsThe bits

- Page 296 and 297: 294 Sequencer InstructionsSQO Instr

- Page 298 and 299: 296 Sequencer Instructions(1) See I

- Page 300 and 301: 298 Program Control InstructionsLBL

- Page 302 and 303: 300 Program Control InstructionsEND

- Page 304 and 305: 302 Program Control InstructionsNot

- Page 306 and 307: 304 Input and Output InstructionsTh

- Page 308 and 309: 306 Input and Output InstructionsAd

- Page 310 and 311: 308 Using InterruptsAn interrupt mu

- Page 312 and 313: 310 Using InterruptsThe priorities

- Page 314 and 315: 312 Using InterruptsUser InterruptI

- Page 316 and 317: 314 Using InterruptsIMPORTANTYou ca

- Page 318 and 319: 316 Using InterruptsTypes of Interr

- Page 320 and 321: 318 Using InterruptsUsing the Selec

- Page 322 and 323: 320 Using InterruptsSTI Error CodeE

- Page 324 and 325: 322 Using InterruptsSTI Error Detec

- Page 326 and 327: 324 Using InterruptsEII Function Fi

- Page 328 and 329: 326 Using InterruptsEII User Interr

- Page 330 and 331: 328 Using InterruptsNotes:Publicati

- Page 332 and 333: 330 Process Control Instructionerro

- Page 334 and 335: 332 Process Control InstructionPID

- Page 336 and 337: 334 Process Control InstructionSetp

- Page 338 and 339: 336 Process Control InstructionOutp

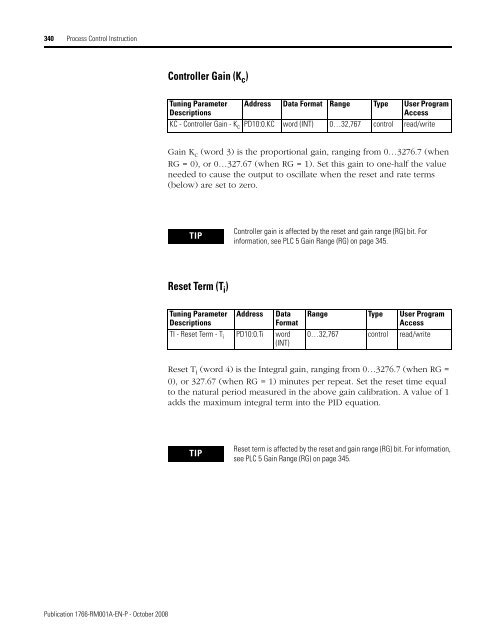

- Page 340 and 341: 338 Process Control InstructionCont

- Page 344 and 345: 342 Process Control InstructionTime

- Page 346 and 347: 344 Process Control InstructionAuto

- Page 348 and 349: 346 Process Control InstructionLoop

- Page 350 and 351: 348 Process Control InstructionEnab

- Page 352 and 353: 350 Process Control InstructionAnal

- Page 354 and 355: 352 Process Control InstructionInpu

- Page 356 and 357: 354 Process Control InstructionZero

- Page 358 and 359: 356 Process Control InstructionPID

- Page 360 and 361: 358 Process Control InstructionReco

- Page 362 and 363: 360 Process Control Instruction4. W

- Page 364 and 365: 362 ASCII InstructionsInstruction T

- Page 366 and 367: 364 ASCII InstructionsSee on page 6

- Page 368 and 369: 366 ASCII InstructionsControl Data

- Page 370 and 371: 368 ASCII InstructionsThis instruct

- Page 372 and 373: 370 ASCII InstructionsTIPYou config

- Page 374 and 375: 372 ASCII InstructionsWhen an error

- Page 376 and 377: 374 ASCII InstructionsExample[I:110

- Page 378 and 379: 376 ASCII InstructionsACB - Number

- Page 380 and 381: 378 ASCII InstructionsACI Instructi

- Page 382 and 383: 380 ASCII InstructionsThe AEX instr

- Page 384 and 385: 382 ASCII Instructions• Channel S

- Page 386 and 387: 384 ASCII Instructions(1) The Contr

- Page 388 and 389: 386 ASCII InstructionsTIPFor inform

- Page 390 and 391: 388 ASCII InstructionsASR Instructi

- Page 392 and 393:

390 ASCII InstructionsExamplesFor t

- Page 394 and 395:

392 ASCII InstructionsASCII Charact

- Page 396 and 397:

394 Communications Instructions•

- Page 398 and 399:

396 Communications InstructionsSVC

- Page 400 and 401:

398 Communications InstructionsThe

- Page 402 and 403:

400 Communications InstructionsMess

- Page 404 and 405:

402 Communications InstructionsMess

- Page 406 and 407:

404 Communications Instructions“C

- Page 408 and 409:

406 Communications InstructionsErro

- Page 410 and 411:

408 Communications Instructions2. A

- Page 412 and 413:

410 Communications InstructionsComm

- Page 414 and 415:

412 Communications Instructions0000

- Page 416 and 417:

414 Communications InstructionsExam

- Page 418 and 419:

416 Communications InstructionsComm

- Page 420 and 421:

418 Communications InstructionsData

- Page 422 and 423:

420 Communications InstructionsMess

- Page 424 and 425:

422 Communications InstructionsData

- Page 426 and 427:

424 Communications Instructions•

- Page 428 and 429:

426 Communications InstructionsPara

- Page 430 and 431:

428 Communications Instructionsinte

- Page 432 and 433:

430 Communications InstructionsExam

- Page 434 and 435:

432 Communications InstructionsExam

- Page 436 and 437:

434 Communications Instructions“T

- Page 438 and 439:

436 Communications InstructionsIn t

- Page 440 and 441:

438 Communications InstructionsExam

- Page 442 and 443:

TERMABCOMSHLDCHS GNDTXTXTXPWRDC SOU

- Page 444 and 445:

442 Communications InstructionsConf

- Page 446 and 447:

444 Communications InstructionsLoca

- Page 448 and 449:

446 Communications InstructionsNetw

- Page 450 and 451:

448 Communications InstructionsSele

- Page 452 and 453:

450 Communications InstructionsThe

- Page 454 and 455:

452 Communications InstructionsNetw

- Page 456 and 457:

454 Communications InstructionsML14

- Page 458 and 459:

456 Communications InstructionsThe

- Page 460 and 461:

458 Communications Instructions2. A

- Page 462 and 463:

460 Communications InstructionsPubl

- Page 464 and 465:

462 Communications Instructions“T

- Page 466 and 467:

464 Communications InstructionsServ

- Page 468 and 469:

466 Communications InstructionsMSG

- Page 470 and 471:

468 Communications InstructionsErro

- Page 472 and 473:

470 Communications Instructions•

- Page 474 and 475:

472 Communications InstructionsSMTP

- Page 476 and 477:

474 Communications InstructionsConf

- Page 478 and 479:

476 Communications Instructions•

- Page 480 and 481:

478 Communications InstructionsNote

- Page 482 and 483:

480 Socket Interface Using CIP Gene

- Page 484 and 485:

482 Socket Interface Using CIP Gene

- Page 486 and 487:

484 Socket Interface Using CIP Gene

- Page 488 and 489:

486 Socket Interface Using CIP Gene

- Page 490 and 491:

488 Socket Interface Using CIP Gene

- Page 492 and 493:

490 Socket Interface Using CIP Gene

- Page 494 and 495:

492 Socket Interface Using CIP Gene

- Page 496 and 497:

494 Socket Interface Using CIP Gene

- Page 498 and 499:

496 Socket Interface Using CIP Gene

- Page 500 and 501:

498 Socket Interface Using CIP Gene

- Page 502 and 503:

500 Socket Interface Using CIP Gene

- Page 504 and 505:

502 Socket Interface Using CIP Gene

- Page 506 and 507:

504 Socket Interface Using CIP Gene

- Page 508 and 509:

506 Socket Interface Using CIP Gene

- Page 510 and 511:

508 Socket Interface Using CIP Gene

- Page 512 and 513:

510 Socket Interface Using CIP Gene

- Page 514 and 515:

512 Recipe and Data LoggingThe RCP

- Page 516 and 517:

514 Recipe and Data Logging• Desc

- Page 518 and 519:

516 Recipe and Data LoggingApplicat

- Page 520 and 521:

518 Recipe and Data LoggingData Log

- Page 522 and 523:

520 Recipe and Data LoggingNumber o

- Page 524 and 525:

522 Recipe and Data LoggingExample

- Page 526 and 527:

524 Recipe and Data LoggingEnter th

- Page 528 and 529:

526 Recipe and Data LoggingData Log

- Page 530 and 531:

528 Recipe and Data LoggingTable 24

- Page 532 and 533:

530 Recipe and Data LoggingInformat

- Page 534 and 535:

532 Recipe and Data LoggingPublicat

- Page 536 and 537:

534 LCD - LCD InformationThe second

- Page 538 and 539:

536 LCD - LCD InformationLCD Functi

- Page 540 and 541:

538 LCD - LCD InformationLCD Displa

- Page 542 and 543:

540 LCD - LCD Informationafter down

- Page 544 and 545:

542 LCD - LCD InformationLCD contra

- Page 546 and 547:

544 LCD - LCD InformationDisplaying

- Page 548 and 549:

546 MicroLogix 1400 Memory Usage an

- Page 550 and 551:

548 MicroLogix 1400 Memory Usage an

- Page 552 and 553:

550 MicroLogix 1400 Memory Usage an

- Page 554 and 555:

552 System Status FileStatus File O

- Page 556 and 557:

554 System Status FileSign FlagAddr

- Page 558 and 559:

556 System Status FileFault Overrid

- Page 560 and 561:

558 System Status FileThe following

- Page 562 and 563:

560 System Status FileSTI EnabledAd

- Page 564 and 565:

562 System Status FileFree Running

- Page 566 and 567:

564 System Status FileMemory Module

- Page 568 and 569:

566 System Status FileSuspend CodeA

- Page 570 and 571:

568 System Status FileBaud RateAddr

- Page 572 and 573:

570 System Status FileOutgoing Mess

- Page 574 and 575:

572 System Status FileRTC Day of Mo

- Page 576 and 577:

574 System Status FileOS SeriesAddr

- Page 578 and 579:

576 System Status FileNotes:Publica

- Page 580 and 581:

578 Fault Messages and Error CodesM

- Page 582 and 583:

580 Fault Messages and Error CodesE

- Page 584 and 585:

582 Fault Messages and Error CodesE

- Page 586 and 587:

584 Fault Messages and Error CodesE

- Page 588 and 589:

586 Fault Messages and Error CodesN

- Page 590 and 591:

588 Protocol ConfigurationDH-485 Co

- Page 592 and 593:

590 Protocol ConfigurationNumber of

- Page 594 and 595:

592 Protocol ConfigurationDF1 Full-

- Page 596 and 597:

594 Protocol ConfigurationMessage-B

- Page 598 and 599:

596 Protocol Configurationstations

- Page 600 and 601:

598 Protocol ConfigurationStandard

- Page 602 and 603:

600 Protocol ConfigurationDF1 Half-

- Page 604 and 605:

602 Protocol ConfigurationMonitor A

- Page 606 and 607:

604 Protocol ConfigurationDF1 Half-

- Page 608 and 609:

606 Protocol ConfigurationDF1 Radio

- Page 610 and 611:

608 Protocol ConfigurationApplying

- Page 612 and 613:

610 Protocol ConfigurationDF1 Radio

- Page 614 and 615:

612 Protocol ConfigurationThe most

- Page 616 and 617:

614 Protocol ConfigurationModbus RT

- Page 618 and 619:

616 Protocol ConfigurationWhen the

- Page 620 and 621:

618 Protocol ConfigurationModbus Sl

- Page 622 and 623:

620 Protocol ConfigurationSupported

- Page 624 and 625:

622 Protocol ConfigurationModbus Er

- Page 626 and 627:

624 Protocol ConfigurationWhen the

- Page 628 and 629:

626 Protocol ConfigurationEthernet

- Page 630 and 631:

628 Protocol ConfigurationEthernet

- Page 632 and 633:

630 Knowledgebase Quick StartsEnter

- Page 634 and 635:

632 Knowledgebase Quick Starts# 174

- Page 636 and 637:

634 Knowledgebase Quick Starts# 174

- Page 638 and 639:

636 Knowledgebase Quick StartsPrope

- Page 640 and 641:

638 Knowledgebase Quick StartsProbl

- Page 642 and 643:

640 Knowledgebase Quick StartsMicro

- Page 644 and 645:

642 Knowledgebase Quick StartsNote:

- Page 646 and 647:

644 Knowledgebase Quick StartsNotes

- Page 648 and 649:

646 Knowledgebase Quick Starts# 175

- Page 650 and 651:

TERMABCOMSHLDCHS GNDTXTXTXPWRDC SOU

- Page 652 and 653:

650 Knowledgebase Quick StartsFor e

- Page 654 and 655:

652 Knowledgebase Quick StartsIMPOR

- Page 656 and 657:

654 Knowledgebase Quick Starts5. Cl

- Page 658 and 659:

656 Knowledgebase Quick StartsEach

- Page 660 and 661:

658 Knowledgebase Quick StartsDISCO

- Page 662 and 663:

660 Knowledgebase Quick StartsPubli

- Page 664 and 665:

662 Number Systems1x2 14 = 163841x2

- Page 666 and 667:

664 Number Systems2x16 3 = 81921x16

- Page 668 and 669:

666 Number SystemsNotes:Publication

- Page 670 and 671:

668 Glossarycommunication scanA par

- Page 672 and 673:

670 Glossaryfull-duplexA mode of co

- Page 674 and 675:

672 GlossaryModbus RTU SlaveA half-

- Page 676 and 677:

674 GlossaryprocessorA Central Proc

- Page 678 and 679:

676 GlossarysourcingA term used to

- Page 680 and 681:

678 IndexDF1 radio modem parameters

- Page 682 and 683:

680 Indexfree running clock status

- Page 684 and 685:

682 Indexmodem 672modes 672monitori

- Page 686 and 687:

684 Indexscale instruction 208scale

- Page 688 and 689:

686 IndexPublication 1766-RM001A-EN

- Page 690 and 691:

Instruction ListInstruction- Descri

- Page 692:

PLEASE FASTEN HERE (DO NOT STAPLE)O