Hawke Transit System catalogo

Hawke Transit System catalogo

Hawke Transit System catalogo

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

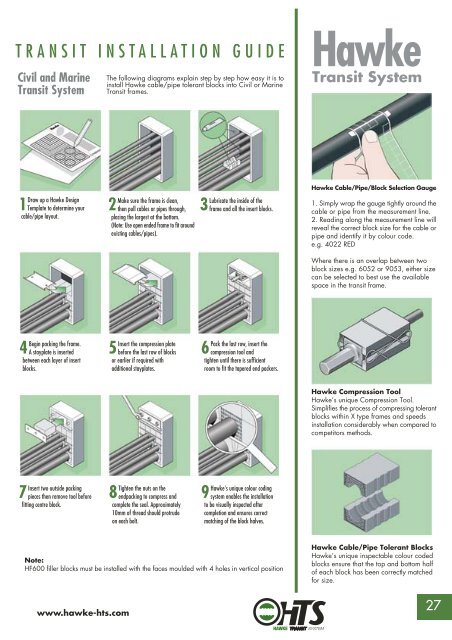

TRANSIT INSTALLATION GUIDECivil and Marine<strong>Transit</strong> <strong>System</strong>The following diagrams explain step by step how easy it is toinstall <strong>Hawke</strong> cable/pipe tolerant blocks into Civil or Marine<strong>Transit</strong> frames.<strong>Hawke</strong><strong>Transit</strong> <strong>System</strong>1Draw up a <strong>Hawke</strong> DesignTemplate to determine yourcable/pipe layout.2Make sure the frame is clean,then pull cables or pipes through,placing the largest at the bottom.(Note: Use open ended frame to fit aroundexisting cables/pipes).Lubricate the inside of the3 frame and all the insert blocks.<strong>Hawke</strong> Cable/Pipe/Block Selection Gauge1. Simply wrap the gauge tightly around thecable or pipe from the measurement line.2. Reading along the measurement line willreveal the correct block size for the cable orpipe and identify it by colour code.e.g. 4022 REDWhere there is an overlap between twoblock sizes e.g. 6052 or 9053, either sizecan be selected to best use the availablespace in the transit frame.4Begin packing the frame.A stayplate is insertedbetween each layer of insertblocks.5Insert the compression platebefore the last row of blocksor earlier if required withadditional stayplates.6Pack the last row, insert thecompression tool andtighten until there is sufficientroom to fit the tapered end packers.<strong>Hawke</strong> Compression Tool<strong>Hawke</strong>’s unique Compression Tool.Simplifies the process of compressing tolerantblocks within X type frames and speedsinstallation considerably when compared tocompetitors methods.7Insert two outside packingpieces then remove tool beforefitting centre block.8Tighten the nuts on theendpacking to compress andcomplete the seal. Approximately10mm of thread should protrudeon each bolt.9<strong>Hawke</strong>’s unique colour codingsystem enables the installationto be visually inspected aftercompletion and ensures correctmatching of the block halves.Note:HF600 filler blocks must be installed with the faces moulded with 4 holes in vertical position<strong>Hawke</strong> Cable/Pipe Tolerant Blocks<strong>Hawke</strong>’s unique inspectable colour codedblocks ensure that the top and bottom halfof each block has been correctly matchedfor size.www.hawke-hts.com27