Slide bearings - Wolf Kunststoff-Gleitlager GmbH

Slide bearings - Wolf Kunststoff-Gleitlager GmbH

Slide bearings - Wolf Kunststoff-Gleitlager GmbH

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

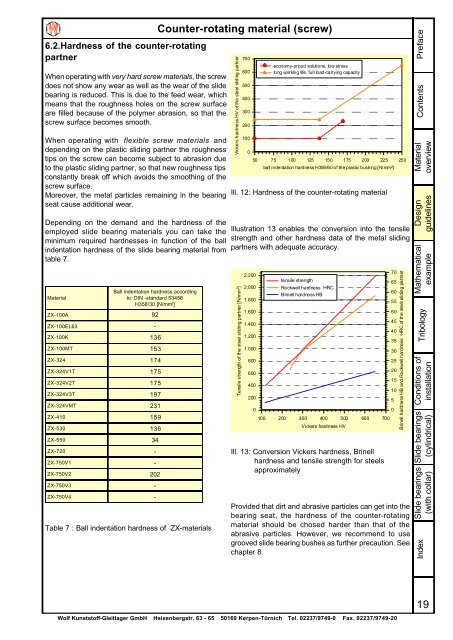

CCCCCC6.2.Hardness of the counter-rotatingpartnerWhen operating with very hard screw materials, the screwdoes not show any wear as well as the wear of the slidebearing is reduced. This is due to the feed wear, whichmeans that the roughness holes on the screw surfaceare filled because of the polymer abrasion, so that thescrew surface becomes smooth.When operating with flexible screw materials anddepending on the plastic sliding partner the roughnesstips on the screw can become subject to abrasion dueto the plastic sliding partner, so that new roughness tipsconstantly break off which avoids the smoothing of thescrew surface.Moreover, the metal particles remaining in the <strong>bearings</strong>eat cause additional wear.Depending on the demand and the hardness of theemployed slide bearing materials you can take theminimum required hardnesses in function of the ballindentation hardness of the slide bearing material fromtable 7.MaterialBall indentation hardness accordingto DIN -standard 53456H358/30 [N/mm 2 ]ZX-100A 92ZX-100EL63 -ZX-100K 136ZX-100MT 153ZX-324 174ZX-324V1T 175ZX-324V2T 175ZX-324V3T 197ZX-324VMT 231ZX-410 159ZX-530 136ZX-550 34ZX-720 -ZX-750V1 -ZX-750V2 202ZX-750V3 -ZX-750V4 -Table 7 : Ball indentation hardness of ZX-materialsCounter-rotating material (screw)Vickers hardness HV of the steel sliding partner7006005004003002001000economy-priced solutions, low stresslong working life, full load-carrying capacity50 75 100 125 150 175 200 225 250ball indentation hardness H358/60of theplastic bushing[N/mm 2]Ill. 12: Hardness of the counter-rotating materialIllustration 13 enables the conversion into the tensilestrength and other hardness data of the metal slidingpartners with adequate accuracy.2Tensile strength of the steel sliding partner [N/mm ]2.2002.0001.8001.6001.4001.2001.0008006004002000tensile strengthRockwell hardness HRCBrinell hardness HB100 200 300 400 500 600 700Vickers hardness HVIll. 13: Conversion Vickers hardness, Brinellhardness and tensile strength for steelsapproximatelyProvided that dirt and abrasive particles can get into thebearing seat, the hardness of the counter-rotatingmaterial should be chosed harder than that of theabrasive particles. However, we recommend to usegrooved slide bearing bushes as further precaution. Seechapter 8.7065605550454035302520151050Brinell hardness HB and Rockwell hardness HRC of the steel sliding partnerPrefaceContentsMaterialoverviewIndex <strong>Slide</strong> <strong>bearings</strong> <strong>Slide</strong> <strong>bearings</strong> Conditions ofTribologyMathematical Design(with collar) (cylindrical) installationexample guidelines<strong>Wolf</strong> <strong>Kunststoff</strong>-<strong>Gleitlager</strong> <strong>GmbH</strong> • Heisenbergstr. 63 - 65 • 50169 Kerpen-Türnich • Tel. 02237/9749-0 • Fax. 02237/9749-2019