Slide bearings - Wolf Kunststoff-Gleitlager GmbH

Slide bearings - Wolf Kunststoff-Gleitlager GmbH

Slide bearings - Wolf Kunststoff-Gleitlager GmbH

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

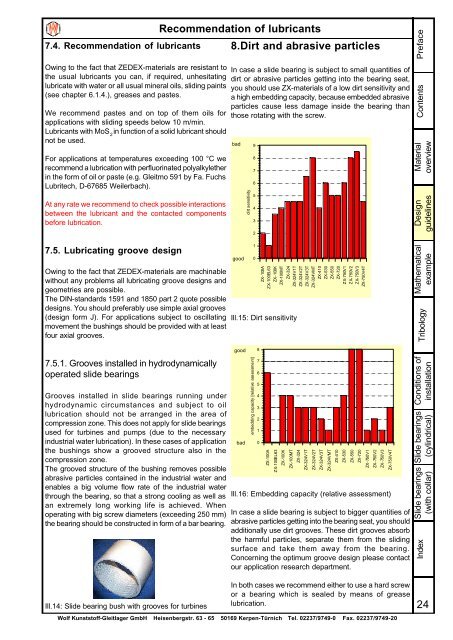

CCCCCC7.4. Recommendation of lubricantsOwing to the fact that ZEDEX-materials are resistant tothe usual lubricants you can, if required, unhesitatinglubricate with water or all usual mineral oils, sliding paints(see chapter 6.1.4.), greases and pastes.We recommend pastes and on top of them oils forapplications with sliding speeds below 10 m/min.Lubricants with MoS 2in function of a solid lubricant shouldnot be used.For applications at temperatures exceeding 100 °C werecommend a lubrication with perfluorinated polyalkyletherin the form of oil or paste (e.g. Gleitmo 591 by Fa. FuchsLubritech, D-67685 Weilerbach).At any rate we recommend to check possible interactionsbetween the lubricant and the contacted componentsbefore lubrication.7.5. Lubricating groove designOwing to the fact that ZEDEX-materials are machinablewithout any problems all lubricating groove designs andgeometries are possible.The DIN-standards 1591 and 1850 part 2 quote possibledesigns. You should preferably use simple axial grooves(design form J). For applications subject to oscillatingmovement the bushings should be provided with at leastfour axial grooves.7.5.1. Grooves installed in hydrodynamicallyoperated slide <strong>bearings</strong>Grooves installed in slide <strong>bearings</strong> running underhydrodynamic circumstances and subject to oillubrication should not be arranged in the area ofcompression zone. This does not apply for slide <strong>bearings</strong>used for turbines and pumps (due to the necessaryindustrial water lubrication). In these cases of applicationthe bushings show a grooved structure also in thecompression zone.The grooved structure of the bushing removes possibleabrasive particles contained in the industrial water andenables a big volume flow rate of the industrial waterthrough the bearing, so that a strong cooling as well asan extremely long working life is achieved. Whenoperating with big screw diameters (exceeding 250 mm)the bearing should be constructed in form of a bar bearing.Recommendation of lubricants8.Dirt and abrasive particlesIn case a slide bearing is subject to small quantities ofdirt or abrasive particles getting into the bearing seat,you should use ZX-materials of a low dirt sensitivity anda high embedding capacity, because embedded abrasiveparticles cause less damage inside the bearing thanthose rotating with the screw.badgooddirt sensitivity9876543210ZX-100AZX-100EL63ZX-100KZX-100MTZX-324ZX-324V1TIll.15: Dirt sensitivitygoodbadembedding capacity [relative assessment]876543210ZX-100AZX-100EL63ZX-100KZX-100MTZX-324V2TZX-324ZX-324V3TZX-324V1TZX-324VMTZX-324V2TIll.16: Embedding capacity (relative assessment)ZX-410ZX-324V3TIn case a slide bearing is subject to bigger quantities ofabrasive particles getting into the bearing seat, you shouldadditionally use dirt grooves. These dirt grooves absorbthe harmful particles, separate them from the slidingsurface and take them away from the bearing.Concerning the optimum groove design please contactour application research department.ZX-530ZX-550ZX-324VMTZX-720ZX-410ZX-750V1ZX-530ZX-750V2ZX-550ZX-750V3ZX-720ZX-750V4TZX-750V1ZX-750V2ZX-750V3ZX-750V4TPrefaceContentsMaterialoverviewIndex <strong>Slide</strong> <strong>bearings</strong> <strong>Slide</strong> <strong>bearings</strong> Conditions ofTribologyMathematical Design(with collar) (cylindrical) installationexample guidelinesIll.14: <strong>Slide</strong> bearing bush with grooves for turbinesIn both cases we recommend either to use a hard screwor a bearing which is sealed by means of greaselubrication.<strong>Wolf</strong> <strong>Kunststoff</strong>-<strong>Gleitlager</strong> <strong>GmbH</strong> • Heisenbergstr. 63 - 65 • 50169 Kerpen-Türnich • Tel. 02237/9749-0 • Fax. 02237/9749-2024