Slide bearings - Wolf Kunststoff-Gleitlager GmbH

Slide bearings - Wolf Kunststoff-Gleitlager GmbH

Slide bearings - Wolf Kunststoff-Gleitlager GmbH

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

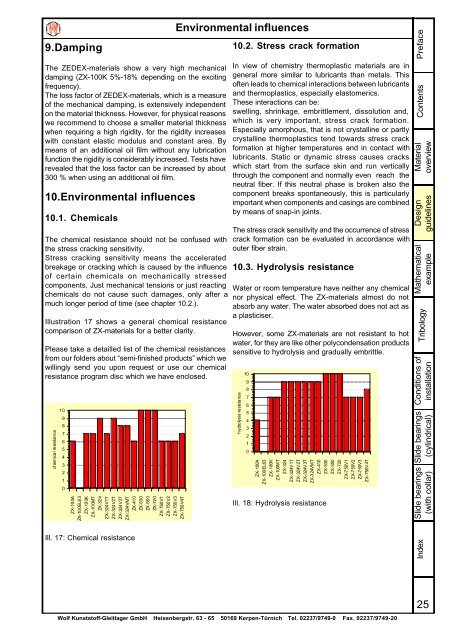

CCCCCC9.DampingThe ZEDEX-materials show a very high mechanicaldamping (ZX-100K 5%-18% depending on the excitingfrequency).The loss factor of ZEDEX-materials, which is a measureof the mechanical damping, is extensively independenton the material thickness. However, for physical reasonswe recommend to choose a smaller material thicknesswhen requiring a high rigidity, for the rigidity increaseswith constant elastic modulus and constant area. Bymeans of an additional oil film without any lubricationfunction the rigidity is considerably increased. Tests haverevealed that the loss factor can be increased by about300 % when using an additional oil film.10.Environmental influences10.1. ChemicalsThe chemical resistance should not be confused withthe stress cracking sensitivity.Stress cracking sensitivity means the acceleratedbreakage or cracking which is caused by the influenceof certain chemicals on mechanically stressedcomponents. Just mechanical tensions or just reactingchemicals do not cause such damages, only after amuch longer period of time (see chapter 10.2.).Illustration 17 shows a general chemical resistancecomparison of ZX-materials for a better clarity.Please take a detailled list of the chemical resistancesfrom our folders about “semi-finished products” which wewillingly send you upon request or use our chemicalresistance program disc which we have enclosed.chemical resistance109876543210ZX-100AZX-100EL63ZX-100KZX-100MTZX-324ZX-324V1TZX-324V2TZX-324V3TZX-324VMTZX-410Ill. 17: Chemical resistanceZX-530ZX-550ZX-720ZX-750V1ZX-750V2Environmental influencesZX-750V3ZX-750V4T10.2. Stress crack formationIn view of chemistry thermoplastic materials are ingeneral more similar to lubricants than metals. Thisoften leads to chemical interactions between lubricantsand thermoplastics, especially elastomerics.These interactions can be:swelling, shrinkage, embrittlement, dissolution and,which is very important, stress crack formation.Especially amorphous, that is not crystalline or partlycrystalline thermoplastics tend towards stress crackformation at higher temperatures and in contact withlubricants. Static or dynamic stress causes crackswhich start from the surface skin and run verticallythrough the component and normally even reach theneutral fiber. If this neutral phase is broken also thecomponent breaks spontaneously, this is particularlyimportant when components and casings are combinedby means of snap-in joints.The stress crack sensitivity and the occurrence of stresscrack formation can be evaluated in accordance withouter fiber strain.10.3. Hydrolysis resistanceWater or room temperature have neither any chemicalnor physical effect. The ZX-materials almost do notabsorb any water. The water absorbed does not act asa plasticiser.However, some ZX-materials are not resistant to hotwater, for they are like other polycondensation productssensitive to hydrolysis and gradually embrittle.hydrolysis resistance109876543210ZX-100AZX-100EL63ZX-100KZX-100MTZX-324ZX-324V1TZX-324V2TZX-324V3TZX-324VMTZX-410ZX-530Ill. 18: Hydrolysis resistanceZX-550ZX-720ZX-750V1ZX-750V2ZX-750V3ZX-750V4TPrefaceContentsMaterialoverviewIndex <strong>Slide</strong> <strong>bearings</strong> <strong>Slide</strong> <strong>bearings</strong> Conditions ofTribologyMathematical Design(with collar) (cylindrical) installationexample guidelines<strong>Wolf</strong> <strong>Kunststoff</strong>-<strong>Gleitlager</strong> <strong>GmbH</strong> • Heisenbergstr. 63 - 65 • 50169 Kerpen-Türnich • Tel. 02237/9749-0 • Fax. 02237/9749-2025