Slide bearings - Wolf Kunststoff-Gleitlager GmbH

Slide bearings - Wolf Kunststoff-Gleitlager GmbH

Slide bearings - Wolf Kunststoff-Gleitlager GmbH

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

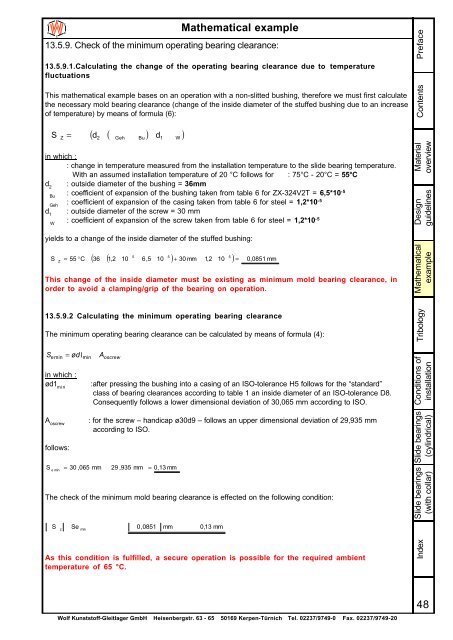

CCCCCCMathematical example13.5.9. Check of the minimum operating bearing clearance:13.5.9.1.Calculating the change of the operating bearing clearance due to temperaturefluctuationsPrefaceThis mathematical example bases on an operation with a non-slitted bushing, therefore we must first calculatethe necessary mold bearing clearance (change of the inside diameter of the stuffed bushing due to an increaseof temperature) by means of formula (6):Contents∆Sϑ Z= ∆ϑ •( d • ( α − α ) − d • α )2GehBu1Win which :∆ϑ : change in temperature measured from the installation temperature to the slide bearing temperature.With an assumed installation temperature of 20 °C follows for ∆ϑ : 75°C - 20°C = 55°Cd 2: outside diameter of the bushing = 36mmα Bu: coefficient of expansion of the bushing taken from table 6 for ZX-324V2T = 6,5*10 -5α Geh: coefficient of expansion of the casing taken from table 6 for steel = 1,2*10 -5d 1: outside diameter of the screw = 30 mmα W: coefficient of expansion of the screw taken from table 6 for steel = 1,2*10 -5MaterialoverviewDesignguidelinesyields to a change of the inside diameter of the stuffed bushing:∆SϑZ= 55 ° C •−5−5−5( 36 • ( 1,2 • 10 − 6,5 • 10 ) + 30 mm • 1,2 • 10 ) = − 0,0851 mmThis change of the inside diameter must be existing as minimum mold bearing clearance, inorder to avoid a clamping/grip of the bearing on operation.Mathematicalexample13.5.9.2 Calculating the minimum operating bearing clearanceThe minimum operating bearing clearance can be calculated by means of formula (4):Semin = ød1min− A oscrewin which :ød1 min:after pressing the bushing into a casing of an ISO-tolerance H5 follows for the “standard”class of bearing clearances according to table 1 an inside diameter of an ISO-tolerance D8.Consequently follows a lower dimensional deviation of 30,065 mm according to ISO.A oscrewfollows:S min: for the screw – handicap ø30d9 – follows an upper dimensional deviation of 29,935 mmaccording to ISO.e= 30 ,065 mm − 29 ,935 mm = 0,13 mmThe check of the minimum mold bearing clearance is effected on the following condition:TribologyConditions ofinstallation<strong>Slide</strong> <strong>bearings</strong>(cylindrical)<strong>Slide</strong> <strong>bearings</strong>(with collar)∆Sϑ z≤ Semin⇒− 0,0851mm≤0,13 mmAs this condition is fulfilled, a secure operation is possible for the required ambienttemperature of 65 °C.Index<strong>Wolf</strong> <strong>Kunststoff</strong>-<strong>Gleitlager</strong> <strong>GmbH</strong> • Heisenbergstr. 63 - 65 • 50169 Kerpen-Türnich • Tel. 02237/9749-0 • Fax. 02237/9749-2048