Slide bearings - Wolf Kunststoff-Gleitlager GmbH

Slide bearings - Wolf Kunststoff-Gleitlager GmbH

Slide bearings - Wolf Kunststoff-Gleitlager GmbH

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

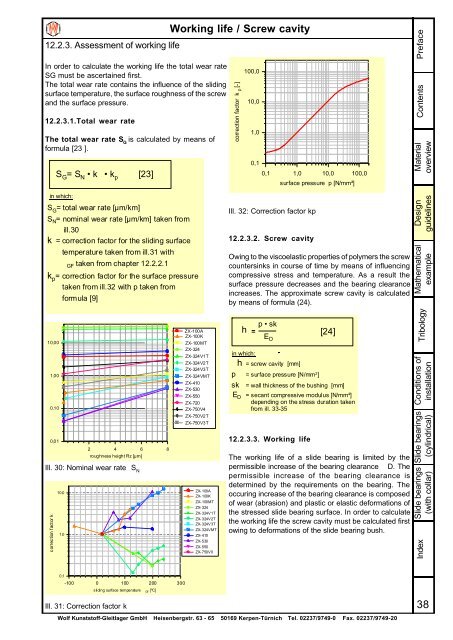

wobei:∆Sϑz=LagerspielveränderungdurchTemperaturver-änderungvonungeschlitztenBuchsen[m]αBu=Ausdehnungskoefizientdes<strong>Gleitlager</strong>sausTab.x[1/?C]∆ϑ=Temperaturveränderung[?C]d2=[m]Buchsenaußendurchmeser[4]∆SϑzαGeh=AusdehnungskoefizientdesGehäusesausTab.x[1/?C]∆ϑα?(d(2?Bu-)+d?αGehw1)d1=Buchseninendurchmeser[m]αw=AusdehnungskoefizientdesGehäusesausTab.x[1/?C]CCCCCC12.2.3. Assessment of working lifeIn order to calculate the working life the total wear rateSG must be ascertained first.The total wear rate contains the influence of the slidingsurface temperature, the surface roughness of the screwand the surface pressure.12.2.3.1.Total wear rateThe total wear rate S Gis calculated by means offormula [23 ].S G= S • k • kNϑp[23]Working life / Screw cavitycorrection factor k [-]p100,010,01,00,10,1 1,0 10,0 100,0surface pressure p [N/mm²]PrefaceContentsMaterialoverviewNin which:S10,001,000,100,012 4 6 8roughness height Rz [µm]Ill. 30: Nominal wear rate S Ncorrection factor k ϑG =10,0total wear rate [µm/km]SN= nominal wear rate [µm/km] taken fromill.30k ϑ = correction factor for the sliding surface1,0temperature taken from ill.31 withtaken from chapter 12.2.2.1ϑ GFk p = correction factor for the surface pressuretaken from ill.32 with p taken fromformula [9]ZX-100AZX-100KZX-100MTZX-324ZX-324V1TZX-324V2TZX-324V3TZX-324VMTZX-410ZX-530ZX-550ZX-720ZX-750V4ZX-750V2TZX-750V3TZX-100AZX-100KZX-100MTZX-324ZX-324V1TZX-324V2TZX-324V3TZX-324VMTZX-410ZX-530ZX-550ZX-750V0Ill. 32: Correction factor kp12.2.3.2. Screw cavityOwing to the viscoelastic properties of polymers the screwcountersinks in course of time by means of influencingcompressive stress and temperature. As a result thesurface pressure decreases and the bearing clearanceincreases. The approximate screw cavity is calculatedby means of formula (24).∆hp • skE Din which:∆h = screw cavity [mm]p = surface pressure [N/mm2]sk = wall thickness of the bushing [mm]E D = secant compressive modulus [N/mm²]depending on the stress duration takenfrom ill. 33-3512.2.3.3. Working life[24]The working life of a slide bearing is limited by thepermissible increase of the bearing clearance ∆D. Thepermissible increase of the bearing clearance isdetermined by the requirements on the bearing. Theoccuring increase of the bearing clearance is composedof wear (abrasion) and plastic or elastic deformations ofthe stressed slide bearing surface. In order to calculatethe working life the screw cavity must be calculated firstowing to deformations of the slide bearing bush.Index <strong>Slide</strong> <strong>bearings</strong> <strong>Slide</strong> <strong>bearings</strong> Conditions ofTribologyMathematical Design(with collar) (cylindrical) installationexample guidelines0,1-100 0 100 200 300sliding surface temperature ϑ GF [ºC]Ill. 31: Correction factor kϑ<strong>Wolf</strong> <strong>Kunststoff</strong>-<strong>Gleitlager</strong> <strong>GmbH</strong> • Heisenbergstr. 63 - 65 • 50169 Kerpen-Türnich • Tel. 02237/9749-0 • Fax. 02237/9749-2038