1972 Olympique - Vintage Snow

1972 Olympique - Vintage Snow

1972 Olympique - Vintage Snow

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

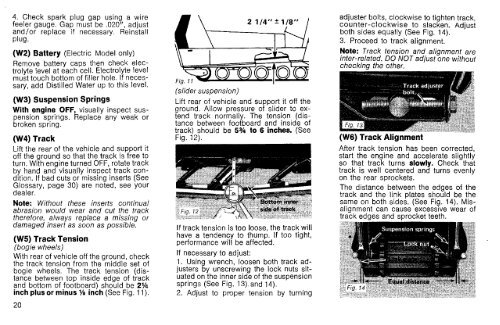

4. Check spark plug gap using a wirefeeler gauge. Gap must be .020", adjustand/or replace if necessary. Reinstallplug.(W2) Battery (Electric Model only)Remove battery caps then check electrolytelevel at each cell. Electrolyte levelmust touch bottom of filler hole. If necessary,add Distilled Water up to this level.(W3) Suspension SpringsWith engine OFF, visually inspect suspensionsprings. Replace any weak orbroken spring.(W4) TrackLift the rear of the vehicle and support itoff the ground so that the track is free toturn. With engine turned OFF, rotate trackby hand and visually inspect track condition.If bad cuts or missing inserts (SeeGlossary, page 30) are noted, see yourdealer.Note: Without these inserts continualabrasion would wear and cut the tracktherefore, always teptece a missing ordamaged insert as soon as possible.(W5) Track Tension(bogie wheels)With rear of vehicle off the ground, checkthe track tension from the middle set ofbogie wheels. The track tension (distancebetween top inside edge of trackand bottom of footboard) should be 21Ainch plus or minus Va inch (See Fig. 11).20Fig. 11 ~"""""'''''IIIIIiIIIii''''''IIIIliiiIl'''I''''''''''''''''''(slider suspension)Lift rear of vehicle and support it off theground. Allow pressure of slider to extendtrack normally. The tension (distancebetween footboard and inside oftrack) should be 5 3 A. to 6 inches. (SeeFig. 12).If track tension is too loose, the track willhave a tendency to thump. If too tight,performance will be affected.If necessary to adjust:1. Using wrench, loosen both track adjustersby unscrewing the lock nuts situatedon the inner side of the suspensionsprings (See Fig. 13).and 14).2. Adjust to proper tension by turningadjuster bolts, clockwise to tighten trackcounter-clockwise to slacken. Adjustboth sides equally (See Fig. 14).3. Proceed to track alignment.Note: Track tension and alignment areinter-related. DO NOT adjust one' withoutchecking the other.(W6) Track AlignmentAfter track tension has been corrected,start the engine and accelerate slightlyso that track turns slowly. Check thattrack is well centered and turns evenlyon the rear sprockets.The distance between the edges of thetrack and the link plates should be thesame on both sides. (See Fig. 14). Misalignmentcan cause excessive wear oftrack edges and sprocket teeth.