Geotextiles in Embankment Dams - Association of State Dam Safety ...

Geotextiles in Embankment Dams - Association of State Dam Safety ...

Geotextiles in Embankment Dams - Association of State Dam Safety ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

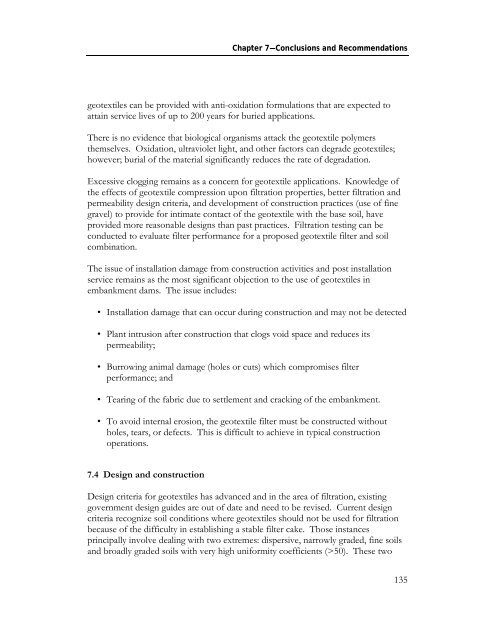

Chapter 7—Conclusions and Recommendationsgeotextiles can be provided with anti-oxidation formulations that are expected toatta<strong>in</strong> service lives <strong>of</strong> up to 200 years for buried applications.There is no evidence that biological organisms attack the geotextile polymersthemselves. Oxidation, ultraviolet light, and other factors can degrade geotextiles;however; burial <strong>of</strong> the material significantly reduces the rate <strong>of</strong> degradation.Excessive clogg<strong>in</strong>g rema<strong>in</strong>s as a concern for geotextile applications. Knowledge <strong>of</strong>the effects <strong>of</strong> geotextile compression upon filtration properties, better filtration andpermeability design criteria, and development <strong>of</strong> construction practices (use <strong>of</strong> f<strong>in</strong>egravel) to provide for <strong>in</strong>timate contact <strong>of</strong> the geotextile with the base soil, haveprovided more reasonable designs than past practices. Filtration test<strong>in</strong>g can beconducted to evaluate filter performance for a proposed geotextile filter and soilcomb<strong>in</strong>ation.The issue <strong>of</strong> <strong>in</strong>stallation damage from construction activities and post <strong>in</strong>stallationservice rema<strong>in</strong>s as the most significant objection to the use <strong>of</strong> geotextiles <strong>in</strong>embankment dams. The issue <strong>in</strong>cludes:• Installation damage that can occur dur<strong>in</strong>g construction and may not be detected• Plant <strong>in</strong>trusion after construction that clogs void space and reduces itspermeability;• Burrow<strong>in</strong>g animal damage (holes or cuts) which compromises filterperformance; and• Tear<strong>in</strong>g <strong>of</strong> the fabric due to settlement and crack<strong>in</strong>g <strong>of</strong> the embankment.• To avoid <strong>in</strong>ternal erosion, the geotextile filter must be constructed withoutholes, tears, or defects. This is difficult to achieve <strong>in</strong> typical constructionoperations.7.4 Design and constructionDesign criteria for geotextiles has advanced and <strong>in</strong> the area <strong>of</strong> filtration, exist<strong>in</strong>ggovernment design guides are out <strong>of</strong> date and need to be revised. Current designcriteria recognize soil conditions where geotextiles should not be used for filtrationbecause <strong>of</strong> the difficulty <strong>in</strong> establish<strong>in</strong>g a stable filter cake. Those <strong>in</strong>stancespr<strong>in</strong>cipally <strong>in</strong>volve deal<strong>in</strong>g with two extremes: dispersive, narrowly graded, f<strong>in</strong>e soilsand broadly graded soils with very high uniformity coefficients (>50). These two135