Geotextiles in Embankment Dams - Association of State Dam Safety ...

Geotextiles in Embankment Dams - Association of State Dam Safety ...

Geotextiles in Embankment Dams - Association of State Dam Safety ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

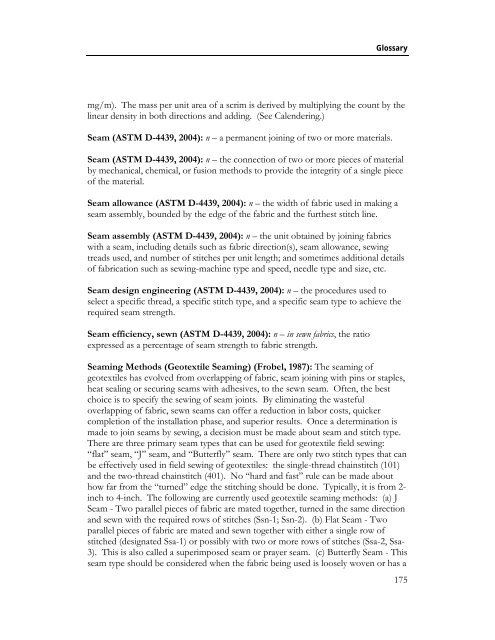

Glossarymg/m). The mass per unit area <strong>of</strong> a scrim is derived by multiply<strong>in</strong>g the count by thel<strong>in</strong>ear density <strong>in</strong> both directions and add<strong>in</strong>g. (See Calender<strong>in</strong>g.)Seam (ASTM D-4439, 2004): n – a permanent jo<strong>in</strong><strong>in</strong>g <strong>of</strong> two or more materials.Seam (ASTM D-4439, 2004): n – the connection <strong>of</strong> two or more pieces <strong>of</strong> materialby mechanical, chemical, or fusion methods to provide the <strong>in</strong>tegrity <strong>of</strong> a s<strong>in</strong>gle piece<strong>of</strong> the material.Seam allowance (ASTM D-4439, 2004): n – the width <strong>of</strong> fabric used <strong>in</strong> mak<strong>in</strong>g aseam assembly, bounded by the edge <strong>of</strong> the fabric and the furthest stitch l<strong>in</strong>e.Seam assembly (ASTM D-4439, 2004): n – the unit obta<strong>in</strong>ed by jo<strong>in</strong><strong>in</strong>g fabricswith a seam, <strong>in</strong>clud<strong>in</strong>g details such as fabric direction(s), seam allowance, sew<strong>in</strong>gtreads used, and number <strong>of</strong> stitches per unit length; and sometimes additional details<strong>of</strong> fabrication such as sew<strong>in</strong>g-mach<strong>in</strong>e type and speed, needle type and size, etc.Seam design eng<strong>in</strong>eer<strong>in</strong>g (ASTM D-4439, 2004): n – the procedures used toselect a specific thread, a specific stitch type, and a specific seam type to achieve therequired seam strength.Seam efficiency, sewn (ASTM D-4439, 2004): n – <strong>in</strong> sewn fabrics, the ratioexpressed as a percentage <strong>of</strong> seam strength to fabric strength.Seam<strong>in</strong>g Methods (Geotextile Seam<strong>in</strong>g) (Frobel, 1987): The seam<strong>in</strong>g <strong>of</strong>geotextiles has evolved from overlapp<strong>in</strong>g <strong>of</strong> fabric, seam jo<strong>in</strong><strong>in</strong>g with p<strong>in</strong>s or staples,heat seal<strong>in</strong>g or secur<strong>in</strong>g seams with adhesives, to the sewn seam. Often, the bestchoice is to specify the sew<strong>in</strong>g <strong>of</strong> seam jo<strong>in</strong>ts. By elim<strong>in</strong>at<strong>in</strong>g the wastefuloverlapp<strong>in</strong>g <strong>of</strong> fabric, sewn seams can <strong>of</strong>fer a reduction <strong>in</strong> labor costs, quickercompletion <strong>of</strong> the <strong>in</strong>stallation phase, and superior results. Once a determ<strong>in</strong>ation ismade to jo<strong>in</strong> seams by sew<strong>in</strong>g, a decision must be made about seam and stitch type.There are three primary seam types that can be used for geotextile field sew<strong>in</strong>g:“flat” seam, “J” seam, and “Butterfly” seam. There are only two stitch types that canbe effectively used <strong>in</strong> field sew<strong>in</strong>g <strong>of</strong> geotextiles: the s<strong>in</strong>gle-thread cha<strong>in</strong>stitch (101)and the two-thread cha<strong>in</strong>stitch (401). No “hard and fast” rule can be made abouthow far from the “turned” edge the stitch<strong>in</strong>g should be done. Typically, it is from 2-<strong>in</strong>ch to 4-<strong>in</strong>ch. The follow<strong>in</strong>g are currently used geotextile seam<strong>in</strong>g methods: (a) JSeam - Two parallel pieces <strong>of</strong> fabric are mated together, turned <strong>in</strong> the same directionand sewn with the required rows <strong>of</strong> stitches (Ssn-1; Ssn-2). (b) Flat Seam - Twoparallel pieces <strong>of</strong> fabric are mated and sewn together with either a s<strong>in</strong>gle row <strong>of</strong>stitched (designated Ssa-1) or possibly with two or more rows <strong>of</strong> stitches (Ssa-2, Ssa-3). This is also called a superimposed seam or prayer seam. (c) Butterfly Seam - Thisseam type should be considered when the fabric be<strong>in</strong>g used is loosely woven or has a175