You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

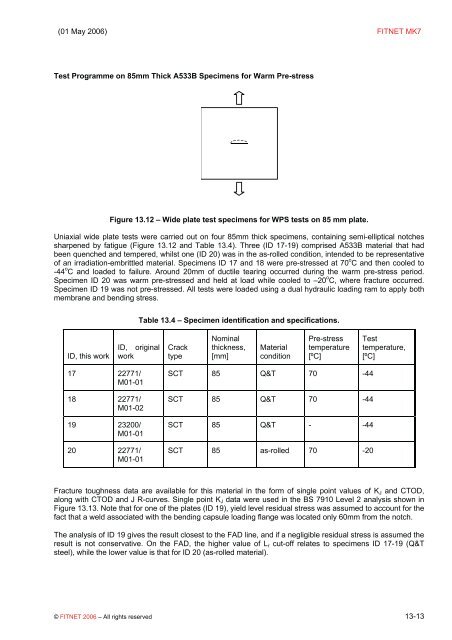

(01 May 2006) FITNET MK7Test Programme on 85mm Thick A533B Specimens for Warm Pre-stressFigure 13.12 – Wide plate test specimens for WPS tests on 85 mm plate.Uniaxial wide plate tests were carried out on four 85mm thick specimens, containing semi-elliptical notchessharpened by fatigue (Figure 13.12 <strong>and</strong> Table 13.4). Three (ID 17-19) comprised A533B material that hadbeen quenched <strong>and</strong> tempered, whilst one (ID 20) was in the as-rolled condition, intended to be representativeof an irradiation-embrittled material. Specimens ID 17 <strong>and</strong> 18 were pre-stressed at 70 o C <strong>and</strong> then cooled to-44 o C <strong>and</strong> loaded to failure. Around 20mm of ductile tearing occurred during the warm pre-stress period.Specimen ID 20 was warm pre-stressed <strong>and</strong> held at load while cooled to –20 o C, where fracture occurred.Specimen ID 19 was not pre-stressed. All tests were loaded using a dual hydraulic loading ram to apply bothmembrane <strong>and</strong> bending stress.Table 13.4 – Specimen identification <strong>and</strong> specifications.ID, this workID, originalworkCracktypeNominalthickness,[mm]MaterialconditionPre-stresstemperature[ºC]Testtemperature,[ºC]17 22771/M01-0118 22771/M01-0219 23200/M01-0120 22771/M01-01SCT 85 Q&T 70 -44SCT 85 Q&T 70 -44SCT 85 Q&T - -44SCT 85 as-rolled 70 -20Fracture toughness data are available for this material in the form of single point values of K J <strong>and</strong> CTOD,along with CTOD <strong>and</strong> J R-curves. Single point K J data were used in the BS 7910 Level 2 analysis shown inFigure 13.13. Note that for one of the plates (ID 19), yield level residual stress was assumed to account for thefact that a weld associated with the bending capsule loading flange was located only 60mm from the notch.The analysis of ID 19 gives the result closest to the FAD line, <strong>and</strong> if a negligible residual stress is assumed theresult is not conservative. On the FAD, the higher value of L r cut-off relates to specimens ID 17-19 (Q&Tsteel), while the lower value is that for ID 20 (as-rolled material).© FITNET 2006 – All rights reserved 13-13