You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

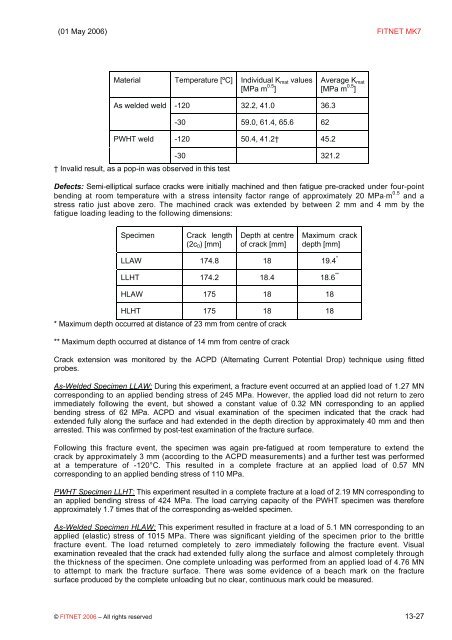

(01 May 2006) FITNET MK7Material Temperature [ºC] Individual K mat values[MPa m 0.5 ]Average K mat[MPa m 0.5 ]As welded weld-120 32.2, 41.0 36.3-30 59.0, 61.4, 65.6 62PWHT weld-120 50.4, 41.2† 45.2† Invalid result, as a pop-in was observed in this test-30 321.2Defects: Semi-elliptical surface cracks were initially machined <strong>and</strong> then fatigue pre-cracked under four-pointbending at room temperature with a stress intensity factor range of approximately 20 MPa⋅m 0.5 <strong>and</strong> astress ratio just above zero. The machined crack was extended by between 2 mm <strong>and</strong> 4 mm by thefatigue loading leading to the following dimensions:SpecimenCrack length(2c 0 ) [mm]Depth at centreof crack [mm]Maximum crackdepth [mm]LLAW 174.8 18 19.4 *LLHT 174.2 18.4 18.6 **HLAW 175 18 18HLHT 175 18 18* Maximum depth occurred at distance of 23 mm from centre of crack** Maximum depth occurred at distance of 14 mm from centre of crackCrack extension was monitored by the ACPD (Alternating Current Potential Drop) technique using fittedprobes.As-Welded Specimen LLAW: During this experiment, a fracture event occurred at an applied load of 1.27 MNcorresponding to an applied bending stress of 245 MPa. However, the applied load did not return to zeroimmediately following the event, but showed a constant value of 0.32 MN corresponding to an appliedbending stress of 62 MPa. ACPD <strong>and</strong> visual examination of the specimen indicated that the crack hadextended fully along the surface <strong>and</strong> had extended in the depth direction by approximately 40 mm <strong>and</strong> thenarrested. This was confirmed by post-test examination of the fracture surface.Following this fracture event, the specimen was again pre-fatigued at room temperature to extend thecrack by approximately 3 mm (according to the ACPD measurements) <strong>and</strong> a further test was performedat a temperature of -120°C. This resulted in a complete fracture at an applied load of 0.57 MNcorresponding to an applied bending stress of 110 MPa.PWHT Specimen LLHT: This experiment resulted in a complete fracture at a load of 2.19 MN corresponding toan applied bending stress of 424 MPa. The load carrying capacity of the PWHT specimen was thereforeapproximately 1.7 times that of the corresponding as-welded specimen.As-Welded Specimen HLAW: This experiment resulted in fracture at a load of 5.1 MN corresponding to anapplied (elastic) stress of 1015 MPa. There was significant yielding of the specimen prior to the brittlefracture event. The load returned completely to zero immediately following the fracture event. Visualexamination revealed that the crack had extended fully along the surface <strong>and</strong> almost completely throughthe thickness of the specimen. One complete unloading was performed from an applied load of 4.76 MNto attempt to mark the fracture surface. There was some evidence of a beach mark on the fracturesurface produced by the complete unloading but no clear, continuous mark could be measured.© FITNET 2006 – All rights reserved 13-27